A Distributed Optical Fiber Sensor for Simultaneous Monitoring of Vibration, Stress, and Temperature

A distributed optical fiber and sensor technology, applied in the optical field, can solve the problem of high cost, and achieve the effect of simplifying the system and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

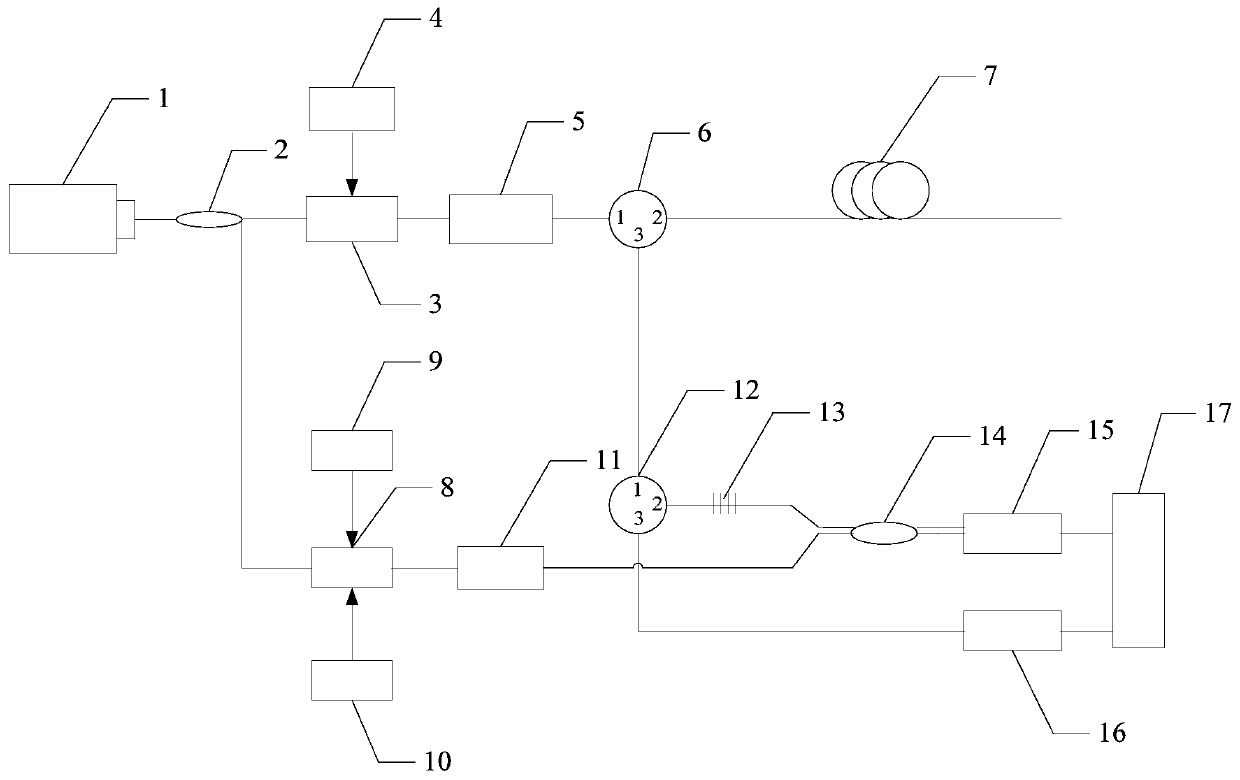

[0023] Specific Embodiment 1: Combining figure 1 , image 3 and Figure 4 Describe this embodiment, a distributed optical fiber sensor that simultaneously monitors vibration, stress, and temperature in this embodiment, the overall structure is as follows figure 1 As shown, it includes: a laser 1, a fiber coupler 2, a first electro-optic modulator 3, an arbitrary function generator 4, an erbium-doped fiber amplifier 5, a first circulator 6, an optical fiber to be tested 7, a second electro-optic modulator 8, Microwave source or single sideband modulator 9, main control board 10, polarization scrambler 11, second circulator 12, fiber grating filter or tunable filter 13, four-port coupler 14, first photodetector 15, The second photodetector 16 and acquisition card 17;

[0024] Described collection card 17 comprises a passage and two passages, and described first photodetector 15 connects a passage of collection card 17, and described second photodetector 16 connects two passag...

specific Embodiment approach 2

[0037] Specific embodiment 2: This embodiment is further defined on the basis of specific embodiment 1, and the coupling ratios of the fiber coupler 2 and the four-port coupler 14 are both between 95:5 and 80:20.

specific Embodiment approach 3

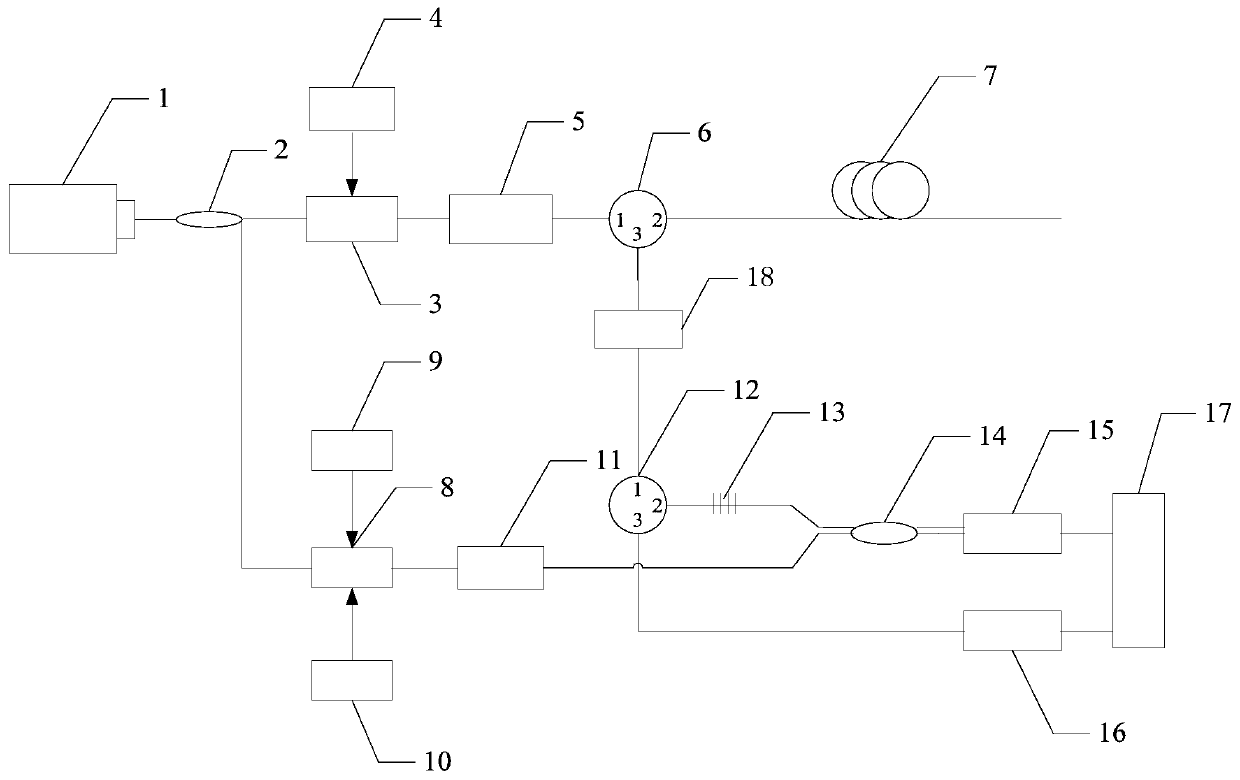

[0038] Embodiment 3: Combining figure 2 Describe this embodiment, the overall structure of this embodiment is as follows figure 2 As shown, the difference from Embodiment 1 is that it also includes an amplifier 18 located between the first circulator 6 and the second circulator 12, and the amplifier 18 is used to amplify the 3-port emission of the first circulator 6 light signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com