An external optical fiber temperature controller and temperature measurement method based on grating temperature measurement technology

An external type, temperature controller technology, applied in the direction of measuring devices, instruments, thermometers, etc., can solve the problems of high cost and loss, achieve short response time, easy reading, and reduce measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

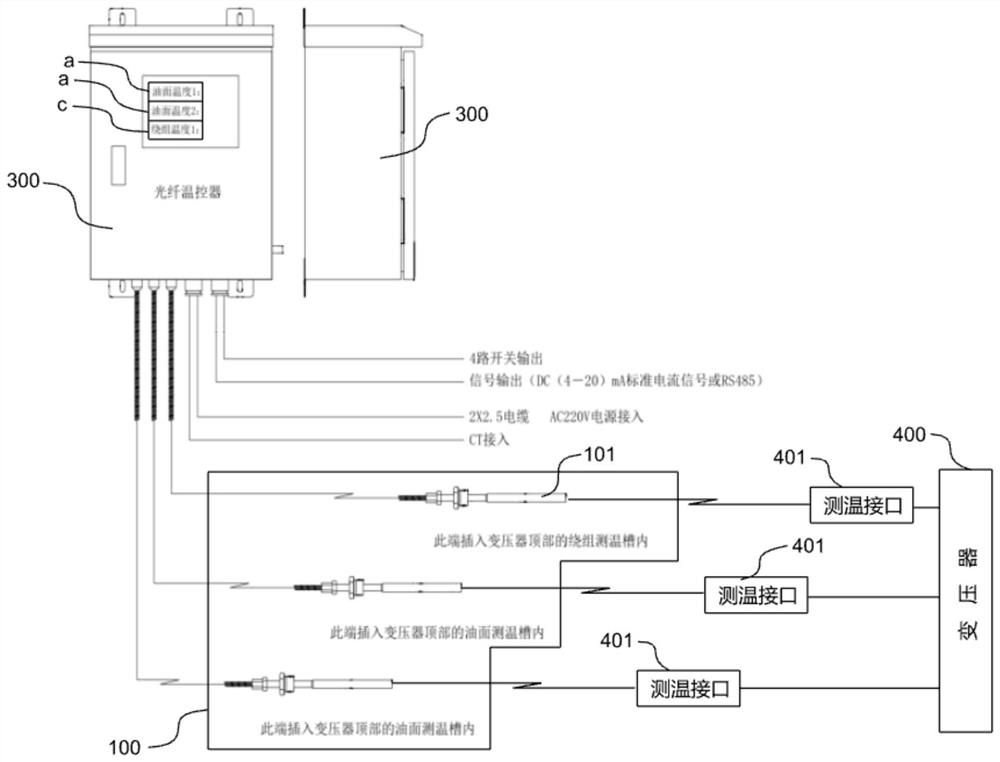

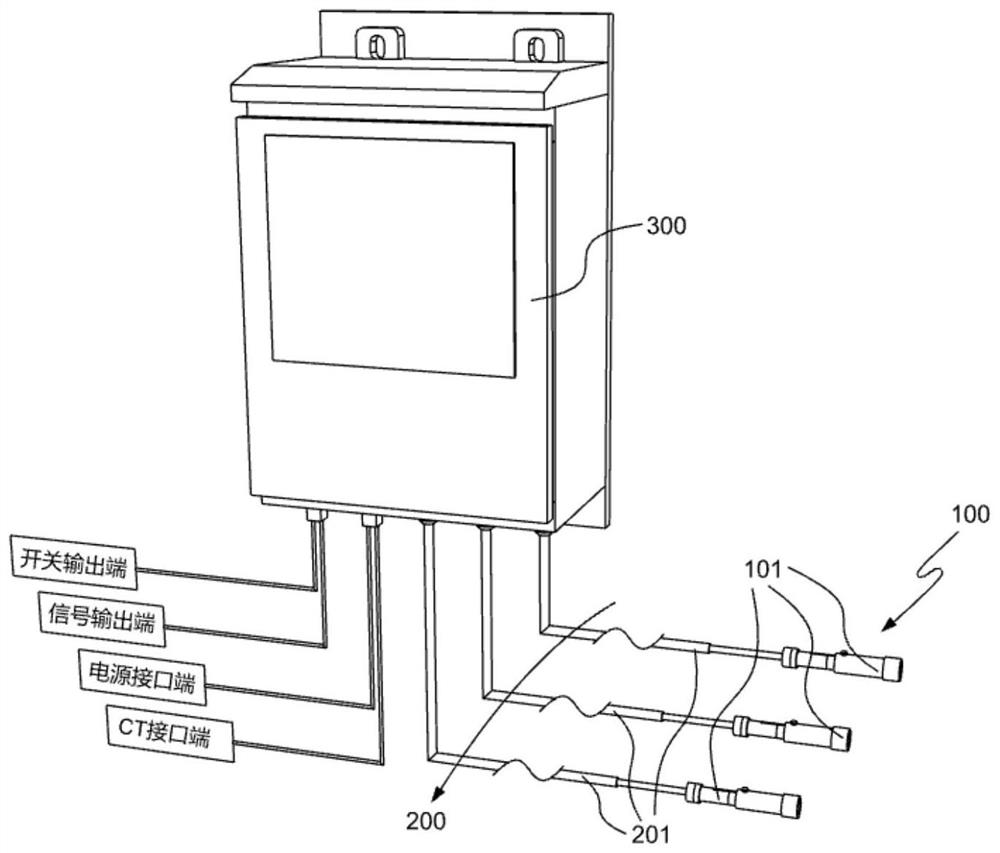

[0049] refer to figure 1 , 2, which is the first embodiment of the present invention. This embodiment provides an external optical fiber temperature controller based on grating temperature measurement technology. Based on grating temperature measurement technology, the temperature of the transformer can be monitored in real time through a detachable external temperature measurement unit. The error Small size, fast response, simple operation, and no need to modify the existing transformers that have been running stably for a long time, the cost is small and the effect is good.

[0050] Specifically, the external optical fiber thermostat based on grating temperature measurement technology includes a temperature measurement unit 100, a signal transmission unit 200, and a signal demodulation display processing unit 300. One end of the signal transmission unit 200 is connected to the temperature measurement unit 100, and the other end Connect with the signal demodulation display p...

Embodiment 2

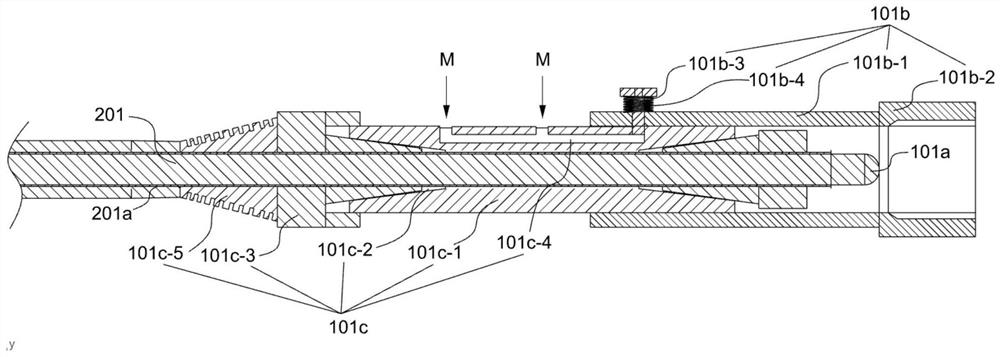

[0057] refer to Figure 3-6 , is the second embodiment of the present invention. The difference from the previous embodiment is that this embodiment allows the optical fiber probe 101a to expand and contract in the connection joint 101b relative to the temperature measurement interface 401, and cooperates with the present invention and the traditional standard measurement The fiber grating temperature measurement method directly connected to the temperature interface 401 can make the measured data more accurate, reduce heat loss and errors, and also protect the fiber optic probe 101a from damage.

[0058] Specifically, the optical fiber 201 is also sleeved with a metal hose 201a and an adapter 101c connected to the connection joint 101b, wherein the adapter 101c is sleeved on the metal hose 201a, and is located on the optical fiber 201 to connect to the optical fiber probe 101a One end of the adapter 101c can be used as a transition point for the telescopic sliding of the fibe...

Embodiment 3

[0066] The following description is the third embodiment of the present invention. This embodiment provides a temperature measurement method for an external optical fiber thermostat based on grating temperature measurement technology. Unlike the previous embodiment, this embodiment provides The method of analyzing and calculating the hot spot temperature b of the winding by analyzing and calculating the data monitored by the temperature controller has small errors and no visual errors. At the same time, the reaction speed of temperature measurement is fast, and the transmission data has no loss.

[0067] Specifically, a temperature measurement method for an external optical fiber thermostat based on grating temperature measurement technology, including calculating the winding hot spot temperature b of the transformer 400 according to the oil surface temperature a of the transformer 400 and the load current value, wherein the oil surface temperature a is determined by the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com