Heat regeneration type vacuum deaerator

A regenerative and deaerator technology, applied in feed water heaters, preheating, chemical instruments and methods, etc., can solve the problems of waste of steam and other heat sources, failure to recycle, waste of water resources, etc., to achieve energy saving and control Easy to operate and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

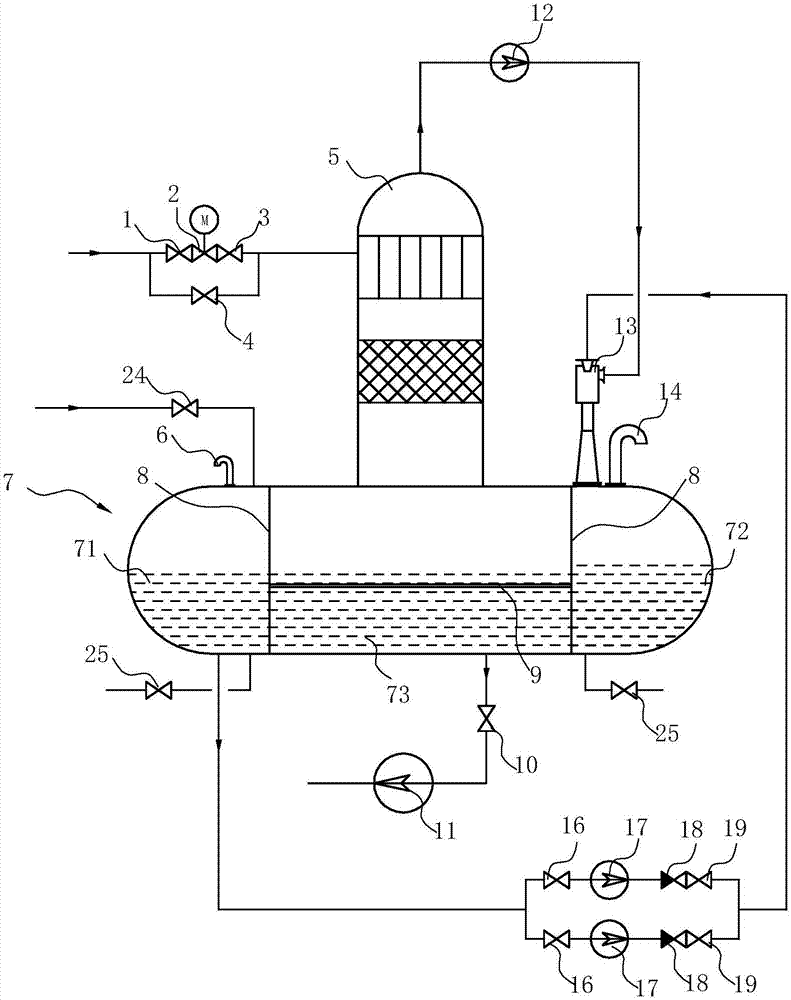

[0020] Such as figure 1 As shown, a regenerative vacuum deaerator, including

[0021] Deoxygenation head 5 adopts the structure in the prior art, and this deoxygenation head 5 comprises the water inlet that is located at the top of deoxygenation head 5 and is connected with the water inlet pipe and the exhaust port that is located at the top of deoxygenation head 5;

[0022] The water tank 7 is connected to the bottom of the deaeration head 5, and the water tank 7 is provided with two spacers 8 to separate the inner chamber of the water tank 7 into a front overflow tank 71, a rear overflow tank 72, and a tank between the front and rear overflow tanks and connected to the deaeration tank. The middle water tank 73 connected to the head 5 is provided with a heat-regenerating heat exchange pipe 9 that can communicate with the front and rear overflow water tanks. The front and rear overflow water tanks 71, 72 and the heat-regeneration heat exchange pipe 9 constitute a heat exchange...

Embodiment 2

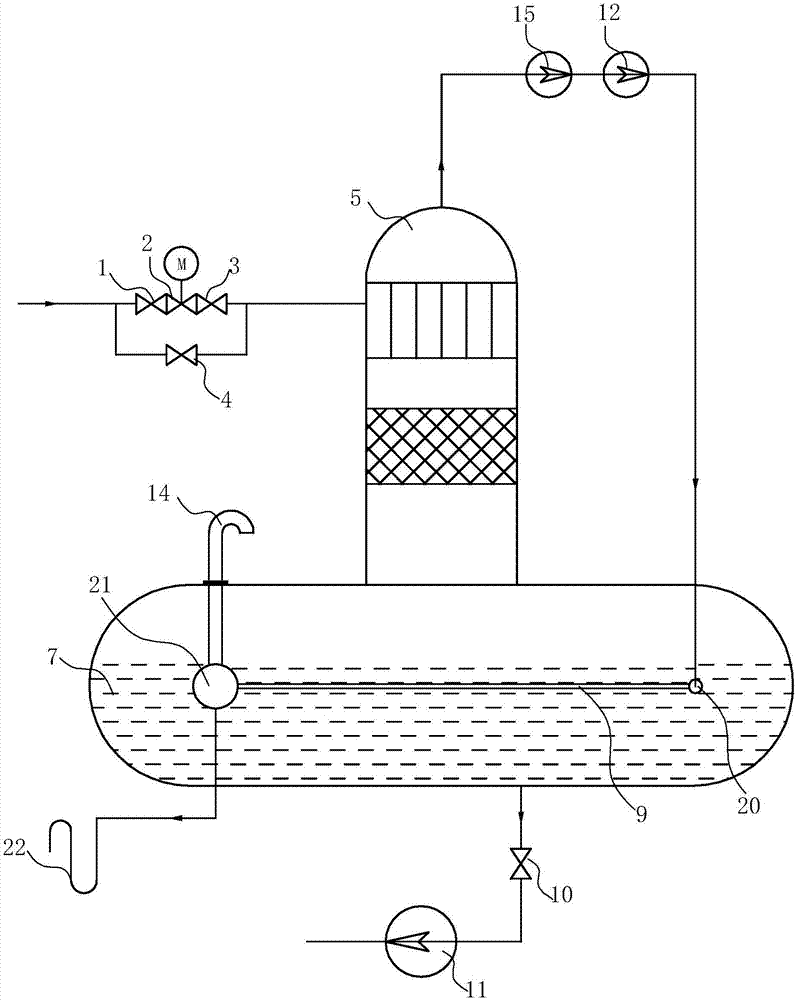

[0031] Such as figure 2 As shown, its structure is roughly the same as that of Embodiment 1, the difference is that the fore-stage vacuum pump of this embodiment adopts screw vacuum pump 12, and the main pump adopts Roots vacuum pump 15, so no working water system is required; The header 20, the gas-water separator 21 and the regenerative heat exchange pipe 9 connected to the exhaust heat recovery header 20 and the gas-water separator 21, the exhaust gas recovery header 20, the gas-water separator 21 and the heat recovery heat exchanger The tube 9 constitutes a heat exchange device, the outlet of the fore-stage vacuum pump is connected to the exhaust heat recovery tank 20, the top of the gas-water separator 21 is provided with an oxygen exhaust pipe 14 exposed to the water tank, and the bottom of the gas-water separator 21 is also It is connected with the steam trap 22 outside the water tank 7 through a pipeline.

[0032] The main process of this embodiment is:

[0033] 1. ...

Embodiment 3

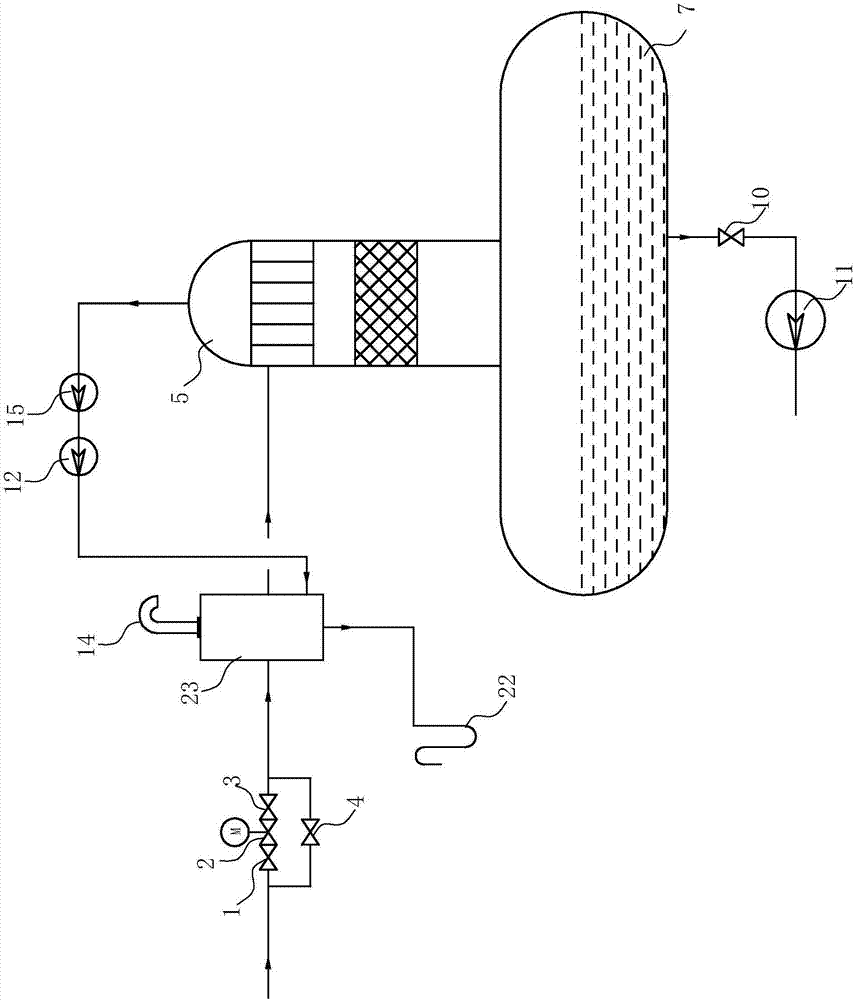

[0036] Such as image 3 As shown, its structure is roughly the same as that of Embodiment 2, the difference is that the heat exchange device of this embodiment is arranged outside the water tank, the heat exchange device is a heat exchanger 23, and the first inlet and the first outlet of the heat exchanger 23 are installed in series. In the water inlet pipe, the second inlet of the heat exchanger 23 is connected to the outlet of the backing vacuum pump (screw vacuum pump 12), and the second outlet of the heat exchanger 23 is connected to the steam trap 22, so as to exchange heat between the gas-vapor mixture and the feed water. Increase feed water temperature.

[0037] The main process of this embodiment is:

[0038] 1. Water supply process: During normal operation, the water supply enters the heat exchanger 23 through the isolation valve 1 before the water inlet regulating valve, the water inlet regulating valve 2, and the rear isolation valve 3 of the water inlet regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com