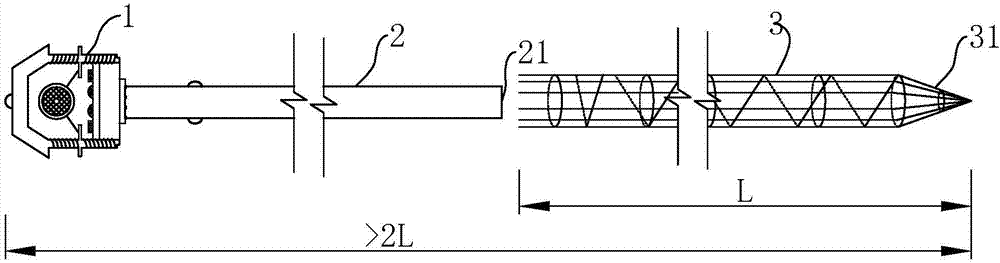

Method for effectively inserting long spiral bored pile with post-inserted cage into vibration pipe

A technology of long helical drilling and vibrating tubes, which is applied to sheet pile walls, buildings, and infrastructure engineering, etc. It can solve the problems of slow pipe penetration and low efficiency, and achieve the effects of reducing pollution, safe and reliable construction, and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

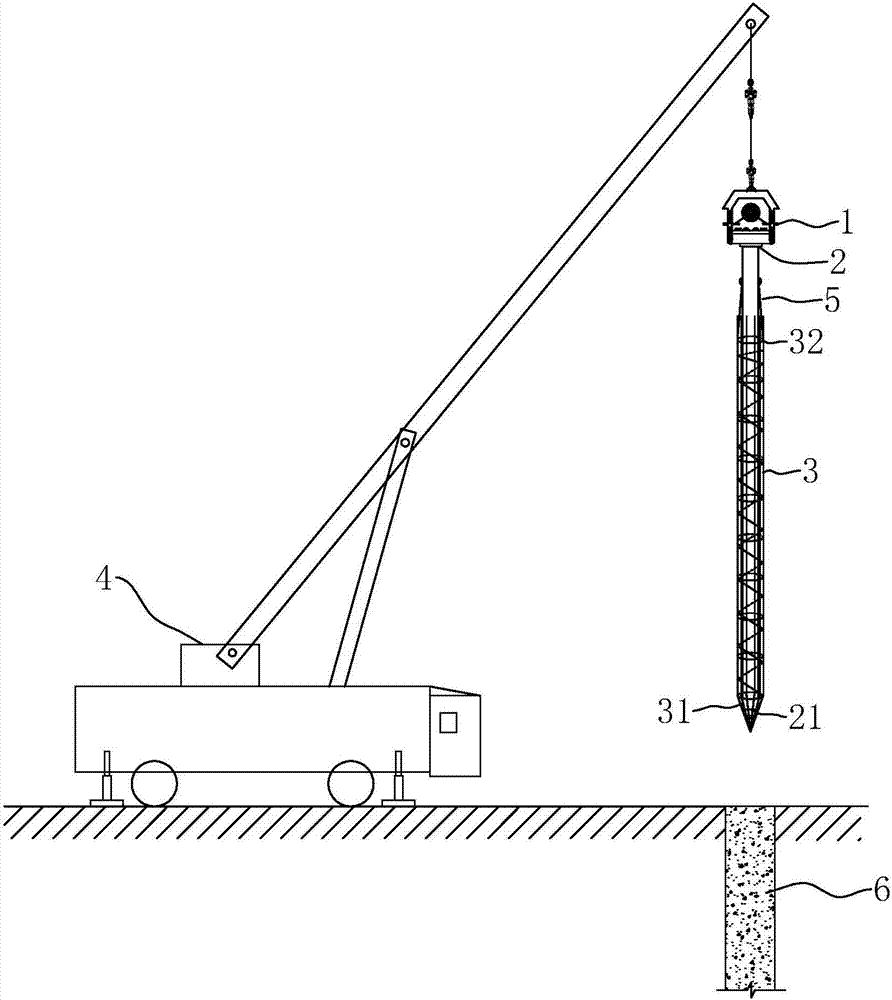

[0047] A method for efficiently inserting vibrating pipes into long auger drilled cast-in-place piles, comprising the following construction steps.

[0048] Step a, such as Figure 4 Shown, drill assembly hole 7 on the ground with the long helical drilling rig of construction concrete pile, and assembly hole 7 diameters are identical with the diameter of construction concrete pile, larger than reinforcement cage 3 diameters. refer to Image 6, 7 holes of assembling hole are darker than reinforcing cage 3 lengths 2~4m, can be 4m, can make reinforcing bar 32 of reinforcing bar 3 leak out assembling hole aperture 71, and make things convenient for the worker to hang lower hook 53 on reinforcing bar 32. Select the steel casing 8 whose diameter is larger than the reinforcement cage 3 and smaller than the assembly hole 7, and drive the steel casing 8 into the assembly hole 7 with the vibrating hammer 1 and the crane 4. The length of the steel casing 8 is greater than the depth of t...

Embodiment 2

[0053] like Figure 8 and Figure 9 As shown, the difference from Example 1 is that when the location of the assembly hole 7 is in good geology and the hole wall is not easy to collapse, the steel casing 8 is not set in the assembly hole 7, but the reinforcement cage 3 at the opening 71 of the assembly hole It needs to be fixed with a temporary fixing device 9, and the specific method is as follows:

[0054] Step b, after the reinforcement cage 3 is vertically lowered into the assembly hole 7, three positioning piles 91 are vertically driven into the ground 2 meters outside the opening of the assembly hole 71, and the three positioning piles 91 form an equilateral triangle. A pull-joint rope 92 with fixed hook 93 is bolted on one end, hooks the reinforcing rib 32 on the reinforcement cage 3 with the fix hook 93, and three pull-join ropes 92 have the same length, and when they are all in a tight state, the center of the reinforcement cage 3 That is, it is located in the cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com