Open-cut rock anchoring combined basic and inverse work construction method thereof

A combination of foundation and construction method technology, applied in the direction of basic structure engineering, architecture, bridge construction, etc., can solve the problems of high cost and construction period, difficult foundation construction, high difficulty of drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

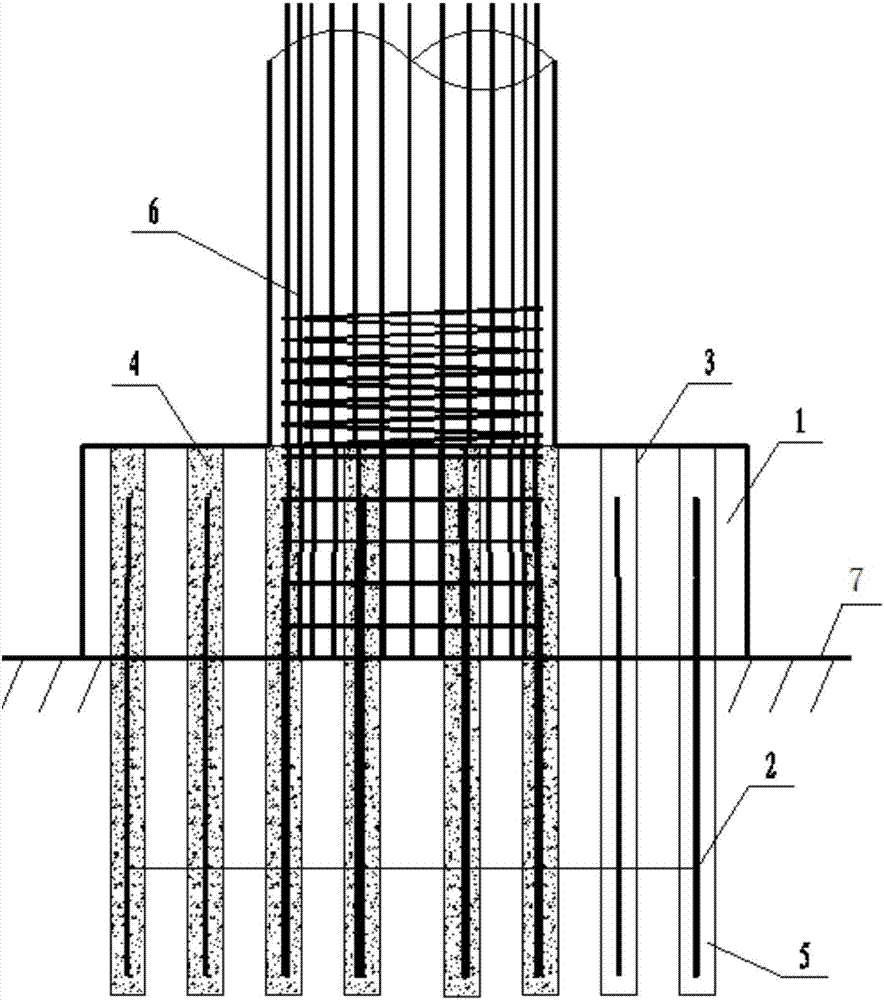

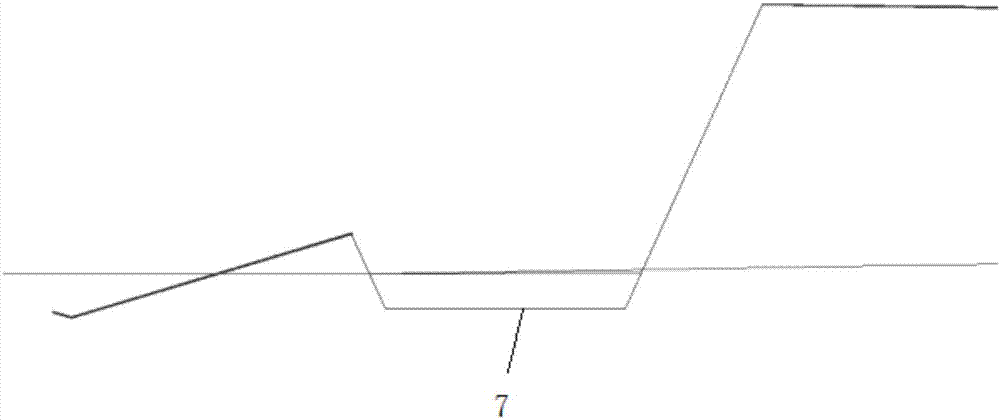

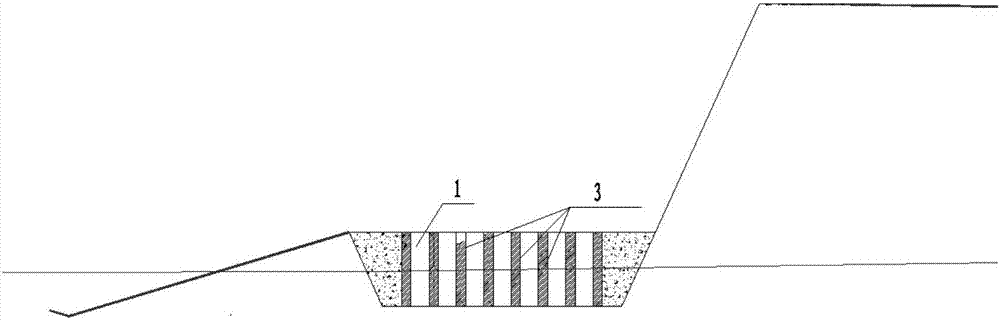

[0024] Such as figure 1 As shown, an open-cut rock-anchor composite foundation includes an open-cut cap 1 and an anchor rod 2. The open-cut cap 1 is set on the bedrock 7 and is a reinforced concrete rectangular structure. The design check indicators such as compression resistance and thrust resistance , anti-overturning, etc. all meet the design index requirements of conventional open cut foundations. A positioning sleeve 3 is pre-embedded in the open excavation cap 1, and the positioning sleeve 3 is mostly a steel pipe, which is used as a positioning guide hole for the construction of a bolter rig, and its diameter is 0.5 to 2 cm larger than that of the bolt 2. The positioning sleeves 3 include three groups, the middle group is annularly distributed, the middle group of positioning sleeves 3 corresponds to the pier body 8, and there is a row o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com