Aggregated type spun yarn super large drafting device and spinning technology

A super-drafting and spun yarn technology, which is applied in spinning machines, drafting equipment, textiles and papermaking, etc., can solve the problems of low yarn quality, low yarn efficiency, and high production costs, and achieve increased tightness and improved Yarn structure, anti-diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

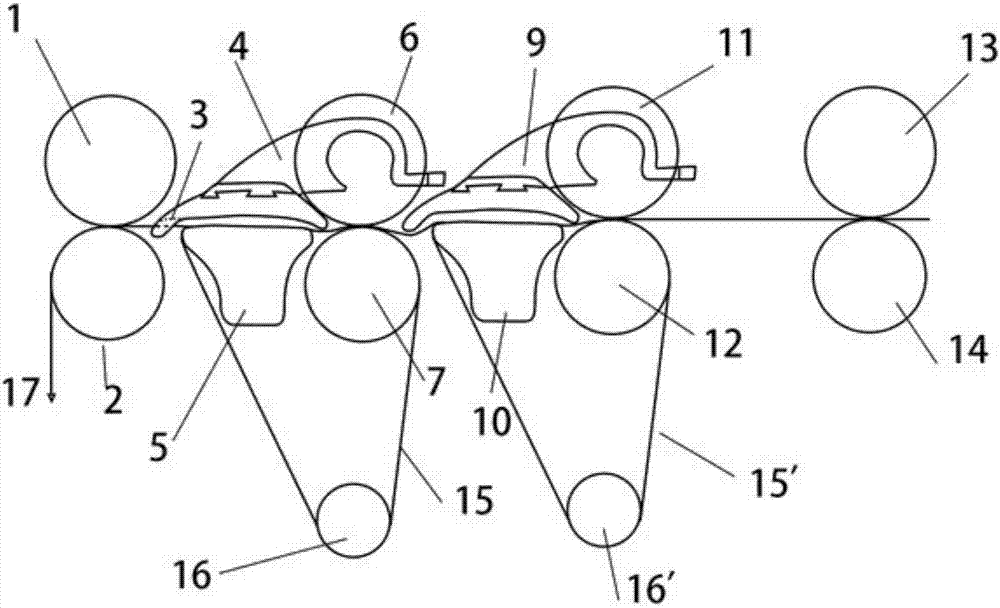

[0064] A concentrated spun yarn super large drafting device, such as figure 1 As shown, the drafting device is a four-roller drafting system, including two main drafting areas and a post-drafting area. The main drafting zone is successively the rear main drafting zone and the front main drafting zone, and the drafting rear zone, the rear main drafting zone and the front main drafting zone are successively closely adjacent to each other.

[0065] The drafting rear area is composed of the rear area traction member and the rear area clamping member; the rear area traction member is the rear top roller 11 of the rear main drafting area and the rear roller 12 of the rear main drafting area matched with it; the rear area clamping The components are the rear top roller 13 in the drafting area and the rear roller 14 in the drafting area matched with it. The distance between the centers of the rear rollers 14 is 25.1 mm.

[0066]The rear main drafting area is composed of the rear mai...

Embodiment 2

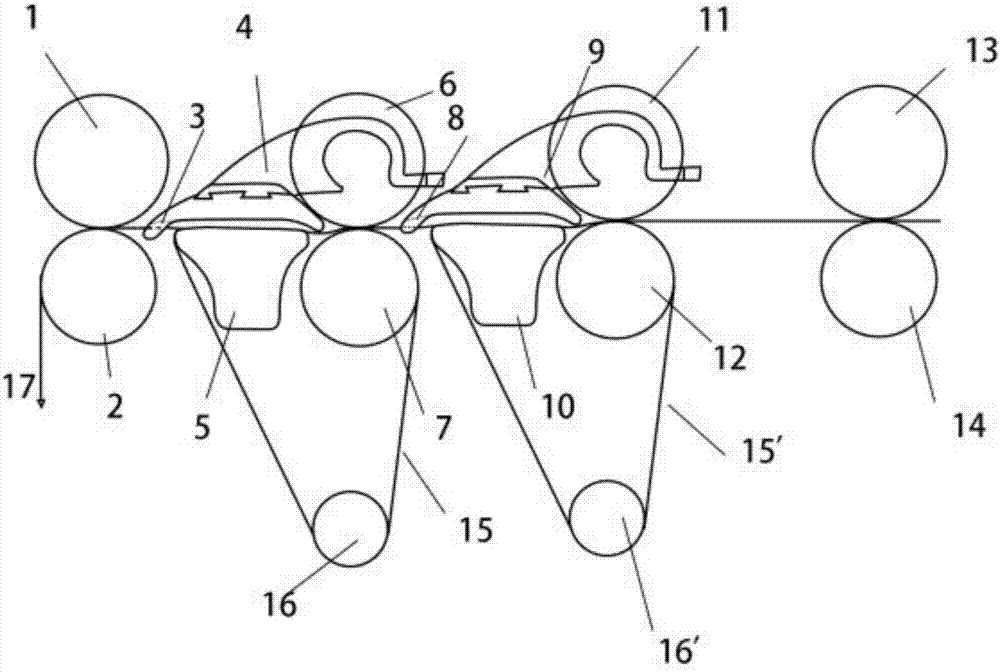

[0076] A kind of ladder gathering type spun yarn super large drafting device, such as figure 2 As shown, the drafting device is a four-roller drafting system, which is basically the same in structure as in Example 1, except that the rear upper pin is as Figure 13 As shown, there is an accumulation groove on the bonding surface of the strands, which is the accumulation groove 8 in the rear main drafting area. The track of the accumulation groove is parabolic. The depth of the accumulation groove gradually deepens according to the running direction of the strands. The inlet width of the accumulation groove is 20mm, the outlet width is 3.25mm, and the maximum outlet depth is 4mm. The rear upper pin 9 and the rear lower pin 10 are made of high wear-resistant alloy steel. And after ceramic treatment, its surface roughness is 3.20μm; the entrance width of the collecting groove in the front main drafting area is 3.25mm, the exit width is 0.1mm, and the maximum exit depth is 0.1mm; ...

Embodiment 3

[0081] A concentrated spun yarn super large drafting device, such as image 3 As shown, the drafting device is a four-roller drafting system, and its structure is basically the same as that of Embodiment 1, except that the lower end surface of the upper pin and the upper end surface of the lower pin cooperate with each other in the front main drafting zone and the rear main drafting zone It is a unimodal structure, and the unimodal is formed by the upper end of the lower pin protruding upwards, and the gathering grooves of the two upper pins are as follows Figure 14 As shown, the trajectory is an "eight" shape, the ratio of the peak bottom width to peak height in the front main drafting area is 1:0.10, and the ratio of peak bottom width to peak height in the rear main drafting area is 1:1.80; The entrance width of the gathering groove in the stretching area is 1.5mm, the exit width is 0.8mm, and the maximum exit depth is 1mm. The surface roughness of the front upper pin and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com