Process using synthetic gas and fluidized bed to prepare methanol based on interstage absorption and separation

A technology for producing methanol and synthesis gas, applied in the field of coal chemical industry, can solve the problems of reducing fluidized bed heat pipes, short service life, catalyst poisoning and deactivation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

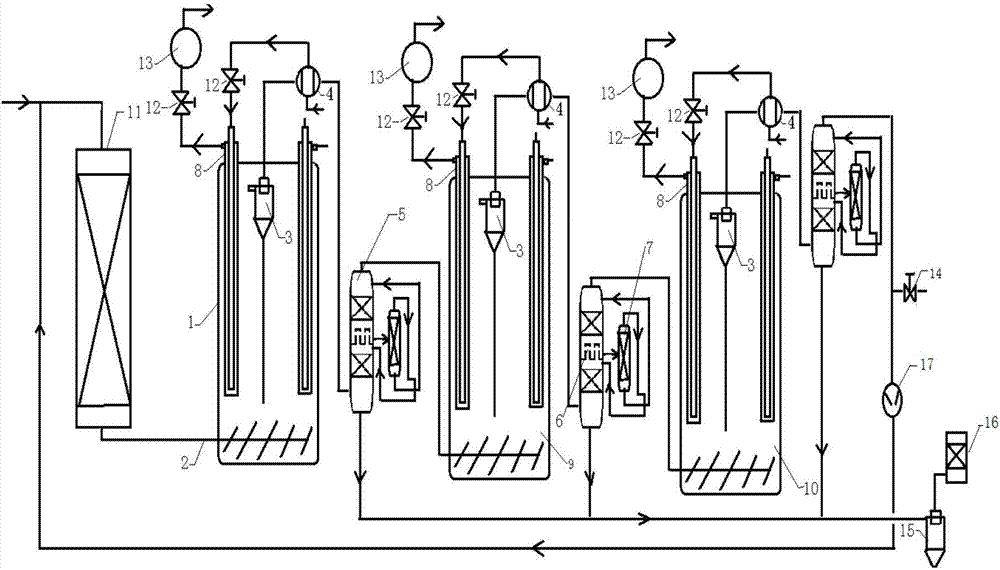

[0020] Embodiment, reaction system adopts methanol fixed-bed pre-reactor (11) and the methanol fluidized-bed reactor of two or more stages in series to form, will convert CO / H 2 The 1:2 purified synthesis gas passes through the methanol fixed-bed pre-reactor (11) and then passes through the gas distributor (2) into the first-stage methanol fluidized-bed reactor (1) with heat extraction pipes, part of CO and / H 2 At 200-280°C and 3.0-7.0Mpa with a micropowder methanol catalyst with a particle size of 20-200 μm, the homogeneous methanol synthesis reaction occurs through heat exchange through the heat pipe (8), and the product gas passes through the gas-solid separator (3) to remove the catalyst After being cooled by the water cooler (4), it enters the methanol absorption and separation tower (5); after the demethanolization, the product gas enters the methanol fluidized bed reactor with heat pipes at subsequent stages, and repeats the above process; The exhaust valve (14) discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com