A kind of flotation method of mineral with high copper-nickel ratio

A copper-nickel ore and high-copper technology, applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problem of low copper concentrate grade and recovery rate, recovery rate less than 30%, copper recovery rate is not high, etc. problems, to achieve the effect of increasing the effective utilization rate, improving the grade of copper concentrate, and improving the pharmaceutical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

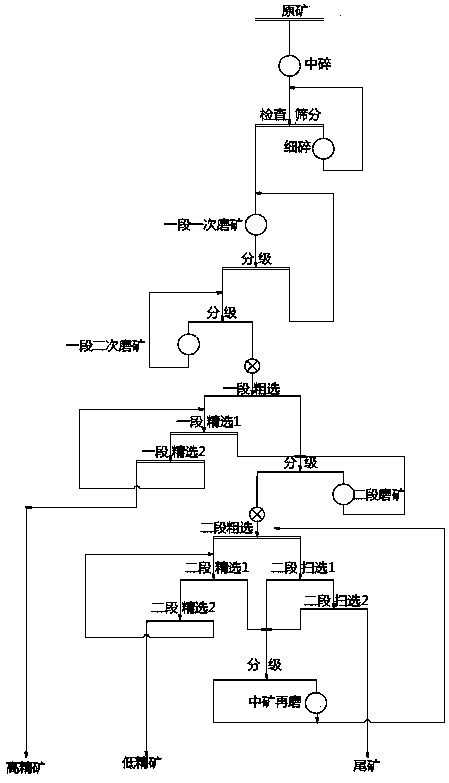

Image

Examples

example 1

[0043] Taking the raw ore containing 1.32% copper, 1.48% nickel, and a copper-nickel ratio of 0.89 as an example, go through the following beneficiation methods:

[0044] A raw material pretreatment

[0045] A.1 Crushing and screening: crush the copper-nickel ore with a high copper-nickel ratio, and obtain a finely crushed product with a particle size of -10 mm through inspection and screening;

[0046] A.2 Grinding and classification

[0047] A.2.1 One-stage grinding: The finely crushed product obtained in step A.1 is subjected to one-stage grinding, and two-stage closed-circuit grinding operations are performed to obtain pulp A1 with a -200 mesh content > 65%, which is used as a raw material for one-stage flotation;

[0048] A.3 Dosing, mixing and stirring

[0049] A.3.1 Put the primary flotation raw material A1 obtained in step A.2.1 into the stirring tank, add ammonium sulfate 800g / t to make the pH value of the pulp reach 8.5; add water to adjust the concentration of the...

example 2

[0067] The raw ore contains 1.136% copper, 1.316% nickel, and a copper-nickel ratio of 0.86. After the following beneficiation methods:

[0068] A raw material pretreatment

[0069] A.1 Crushing and screening: crush the copper-nickel ore with a high copper-nickel ratio, and obtain a finely crushed product with a particle size of -10 mm through inspection and screening;

[0070] A.2 Grinding and classification

[0071] A.2.1 One-stage grinding: The finely crushed product obtained in step A.1 is subjected to one-stage grinding, and two-stage closed-circuit grinding operations are performed to obtain pulp A1 with a -200 mesh content > 65%, which is used as a raw material for one-stage flotation;

[0072] A.3 Dosing, mixing and stirring

[0073] A.3.1 Put the primary flotation raw material A1 obtained in step A.2.1 into the stirring tank, add ammonium sulfate 1000g / t, and make the pH value of the pulp reach 9.0; add water to adjust the concentration of the pulp to 38%, add xanth...

example 3

[0091] The raw ore contains 1.02% copper, 1.29% nickel, and a copper-nickel ratio of 0.79, and undergoes the following beneficiation methods:

[0092] A raw material pretreatment

[0093] A.1 Crushing and screening: crush the copper-nickel ore with a high copper-nickel ratio, and obtain a finely crushed product with a particle size of -10 mm through inspection and screening;

[0094] A.2 Grinding and classification

[0095] A.2.1 One-stage grinding: The finely crushed product obtained in step A.1 is subjected to one-stage grinding, and two-stage closed-circuit grinding operations are performed to obtain pulp A1 with a -200 mesh content > 65%, which is used as a raw material for one-stage flotation;

[0096] A.3 Dosing, mixing and stirring

[0097] A.3.1 Put the primary flotation raw material A1 obtained in step A.2.1 into the stirring tank, add ammonium sulfate 900g / t to make the pH value of the pulp reach 8.7; add water to adjust the concentration of the pulp to 35%, add xa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com