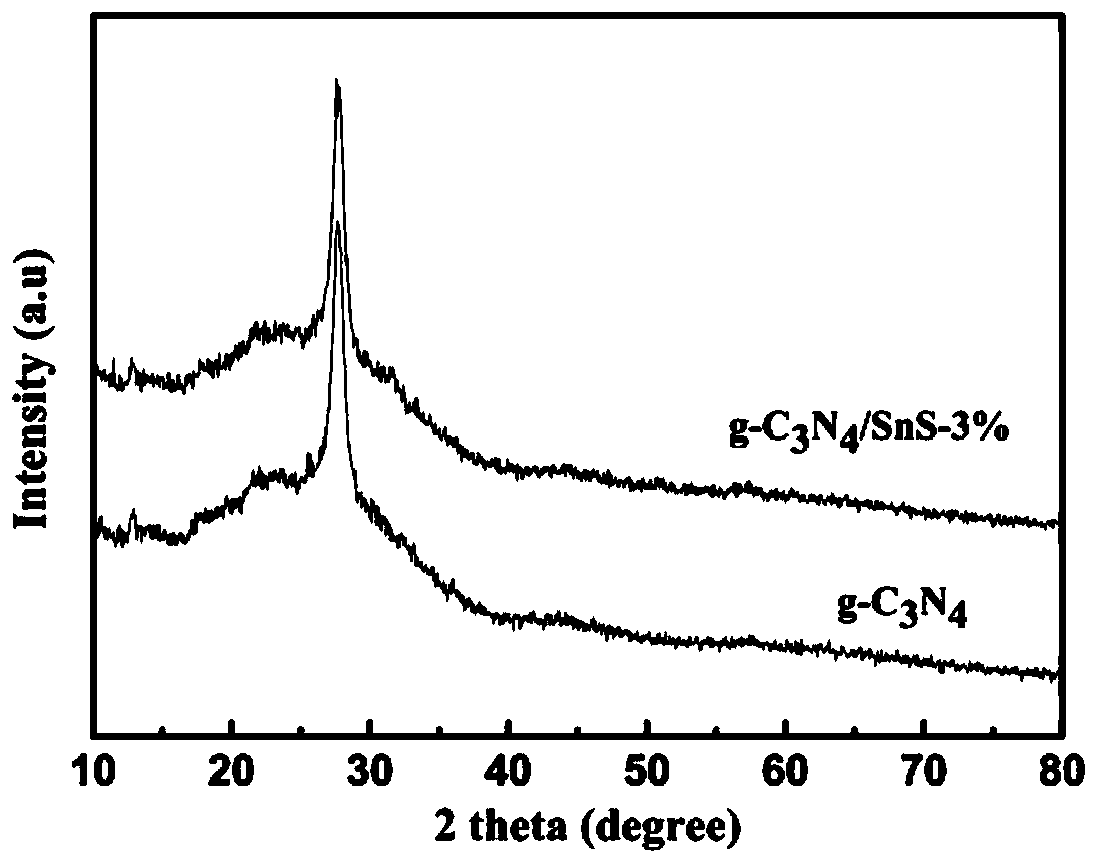

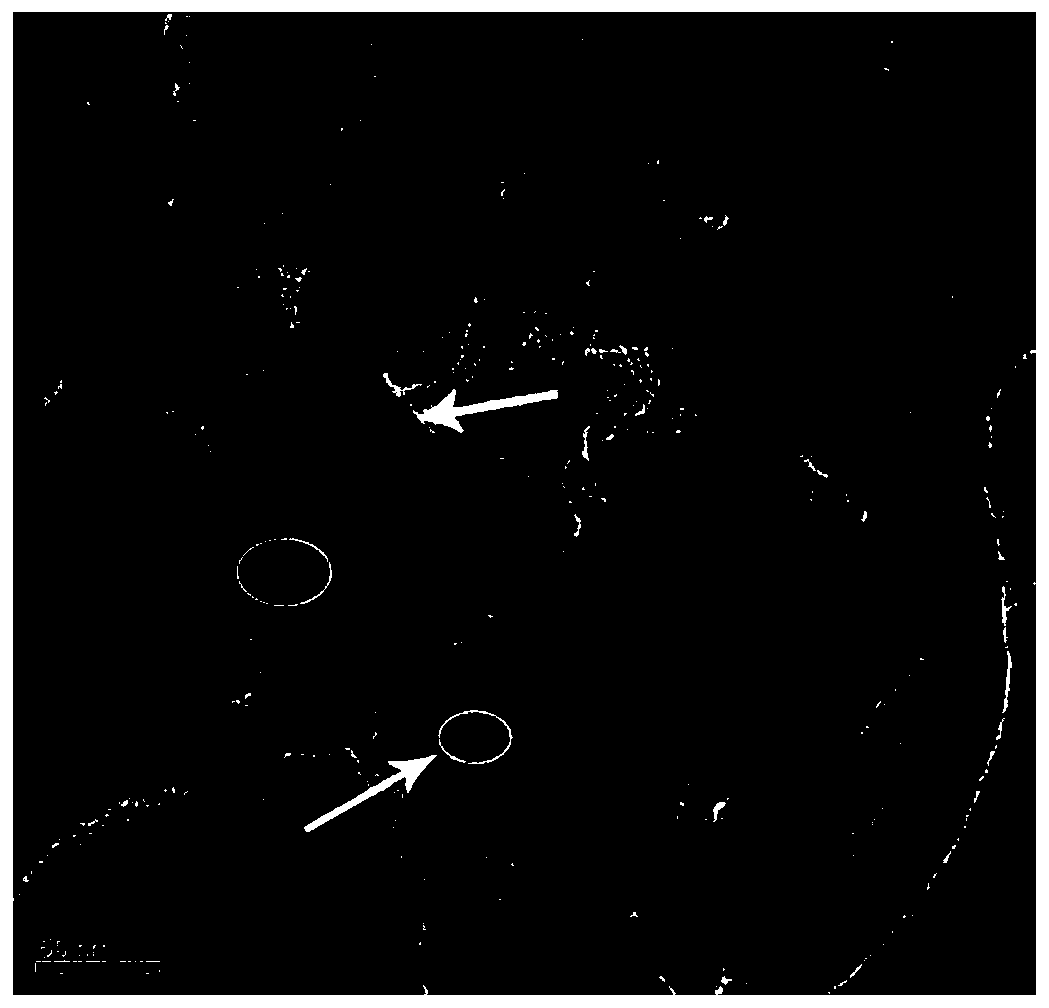

Synthesis method of a kind of graphitic carbon nitride/stannous sulfide nano-heterojunction

A synthesis method, a technology of heterojunction, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of excellent photocatalytic performance, easy operation, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh a certain amount of urea, grind it in an agate mortar and transfer it to a corundum crucible;

[0030] (2) Cover the corundum crucible in step (1) and place it in a muffle furnace for calcination. The heating rate is 3°C / min, the holding temperature is 600°C, and the holding time is 4h. After cooling to room temperature, take it out and collect the product gC 3 N 4 ;

[0031] (3) Weigh a certain amount of SnCl 2 ·2H 2 O is dissolved in deionized water, and uniform SnCl is obtained after thorough stirring 2 Solution, Sn in the resulting solution 2+ The concentration is 0.2mol / L, in SnCl 2 Add a certain amount of g-C to the solution 3 N 4 Nanopowder, stir and mix well, record it as suspension A;

[0032] (4) Weigh a certain amount of sodium sulfide and dissolve it in the solvent water, so that the S 2- The concentration is 0.2 mol / L, and then Na 2 The S solution was added to the suspension A prepared in step (3) at a dropping rate of 0.5 ml / min, and stirred for 2 hours...

Embodiment 2

[0038] (1) Weigh a certain amount of urea, grind it in an agate mortar and transfer it to a corundum crucible;

[0039] (2) Cover the corundum crucible in step (1) and place it in a muffle furnace for calcination. The heating rate is 4℃ / min, the holding temperature is 570℃, and the holding time is 3h. After cooling to room temperature, take it out and collect the product g-C 3 N 4 ;

[0040] (3) Weigh a certain amount of SnCl 2 ·2H 2 O is dissolved in deionized water, and uniform SnCl is obtained after thorough stirring 2 Solution, Sn in the resulting solution 2+ The concentration is 0.2mol / L, in SnCl 2 Add a certain amount of g-C prepared in step (2) to the solution 3 N 4 Nanopowder, stir and mix well; mark it as suspension A;

[0041] (4) Weigh a certain amount of sodium sulfide and dissolve it in the solvent water, so that the S 2- The concentration is 0.2 mol / L, and then Na 2 The S solution was added to the suspension A prepared in step (3) at a dropping rate of 0.5 ml / min, and st...

Embodiment 3

[0045] (1) Weigh a certain amount of urea, grind it in an agate mortar and transfer it to a corundum crucible;

[0046] (2) Cover the corundum crucible in step (1) and place it in a muffle furnace for calcination. The heating rate is 3℃ / min, the holding temperature is 580℃, and the holding time is 3h. After cooling to room temperature, take it out and collect the product g-C 3 N 4 ;

[0047] (3) Weigh a certain amount of SnCl 2 ·2H 2 O is dissolved in deionized water, and uniform SnCl is obtained after thorough stirring 2 Solution, Sn in the resulting solution 2+ The concentration is 0.2mol / L, in SnCl 2 Add a certain amount of g-C prepared in step (2) to the solution 3 N 4 Nanopowder, stir and mix well; mark it as suspension A;

[0048] (4) Weigh a certain amount of sodium sulfide and dissolve it in the solvent water, so that the S 2- The concentration is 0.2 mol / L, and then Na 2 The S solution was added to the suspension A prepared in step (3) at a dropping rate of 0.5 ml / min, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com