Fixing mechanism used for crude oil conveying pipeline machining

A technology for conveying pipelines and fixing mechanisms, which is applied in the direction of workbenches, manufacturing tools, workpiece clamping devices, etc., and can solve problems such as long pipe lengths, difficult control of processing accuracy and stability, and adjustment of support width of brackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

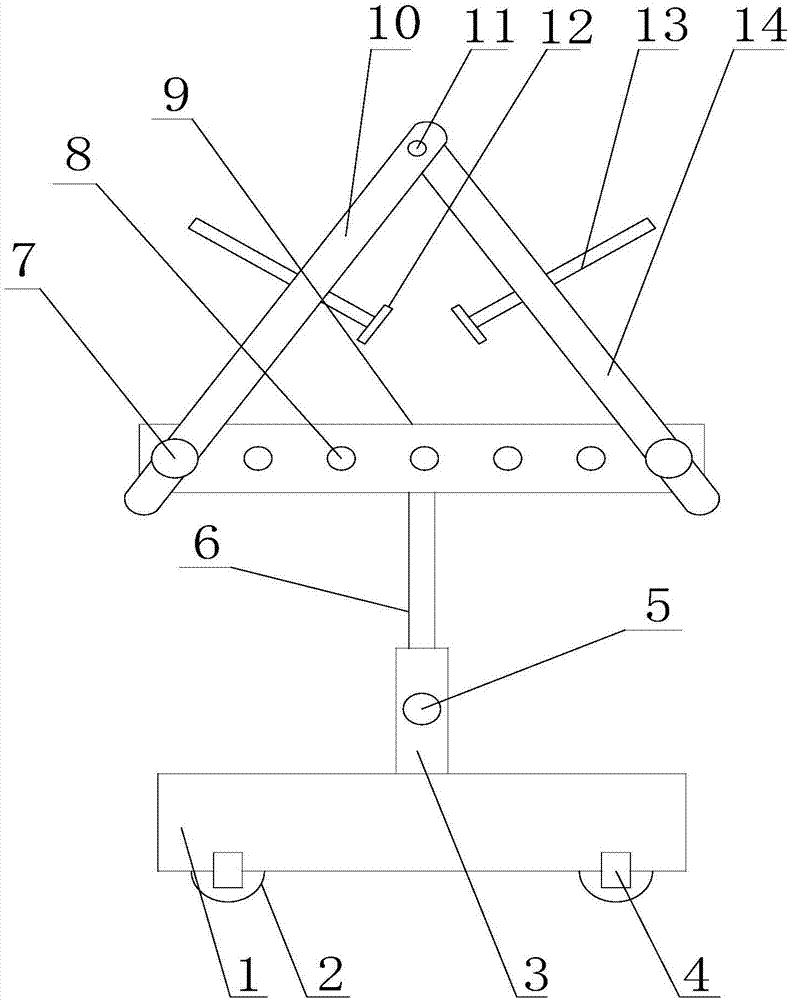

[0024] Such as figure 1 As shown, the fixing mechanism used in the present invention for processing crude oil pipelines includes a placement platform 9, a first baffle 10, and a second baffle 14. The placement platform 9 is a rectangular structure for placing pipes to be processed. The bottom of the placement platform 9 is provided with a support rod 6, the support rod 6 is connected to the central position of the placement platform 9, one end of the support rod 6 is connected with the placement platform 9, and the other end is provided with a sleeve 3, the sleeve 3 is a hollow structure, That is, a through hole is provided on the axial direction of the sleeve 3, the bottom end of the support rod 6 is located in the through hole of the sleeve 3, and an adjusting rod 5 is provided on the outer wall of the sleeve 3, and the adjusting rod 5 and the sleeve 3 are connected by threads , rotate the adjustment rod 5, the adjustment rod 5 can move into the through hole of the sleeve 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com