Nuclear fuel assembly underwater test platform and test method

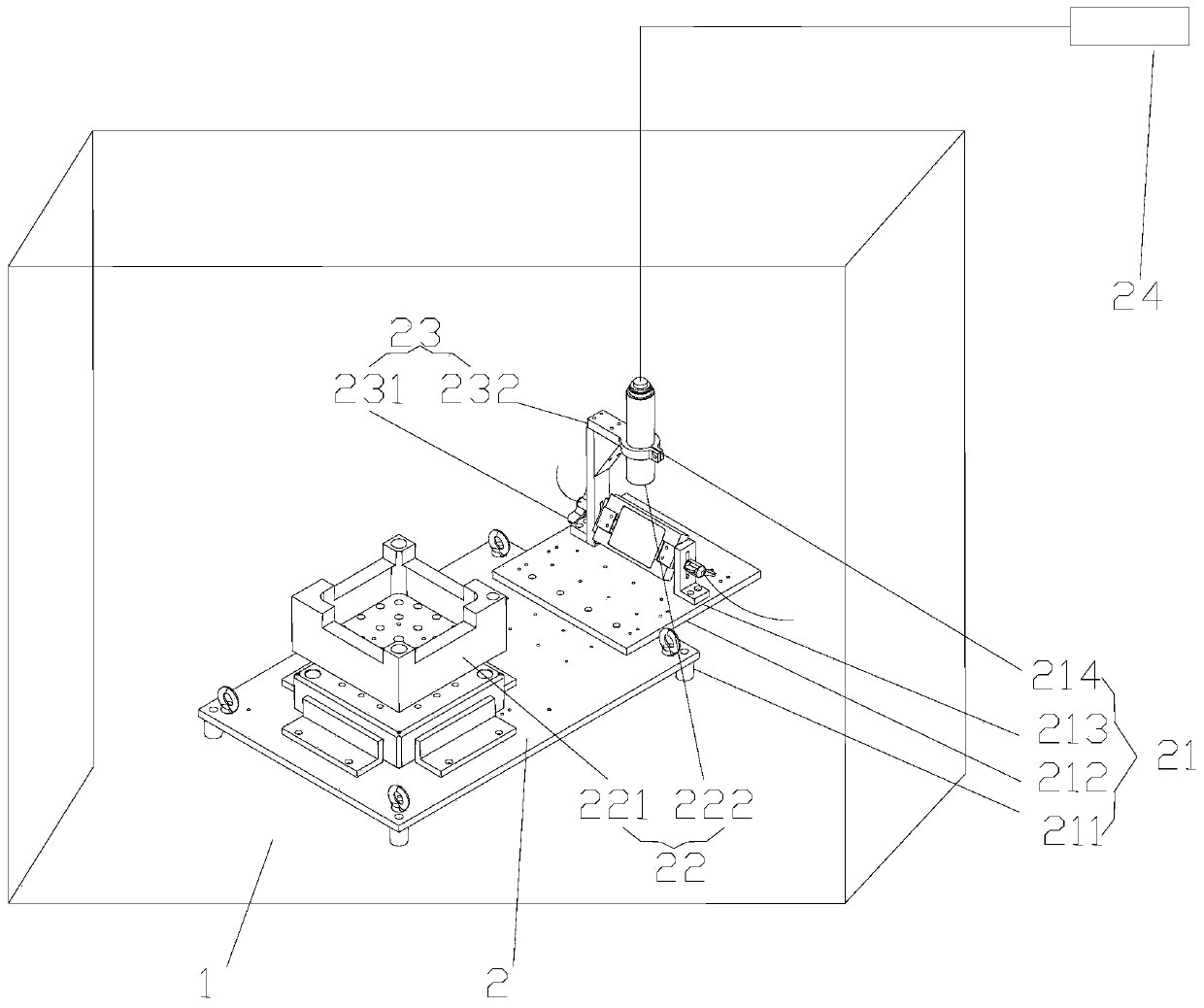

A technology of nuclear fuel assembly and test platform, applied in the field of nuclear power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

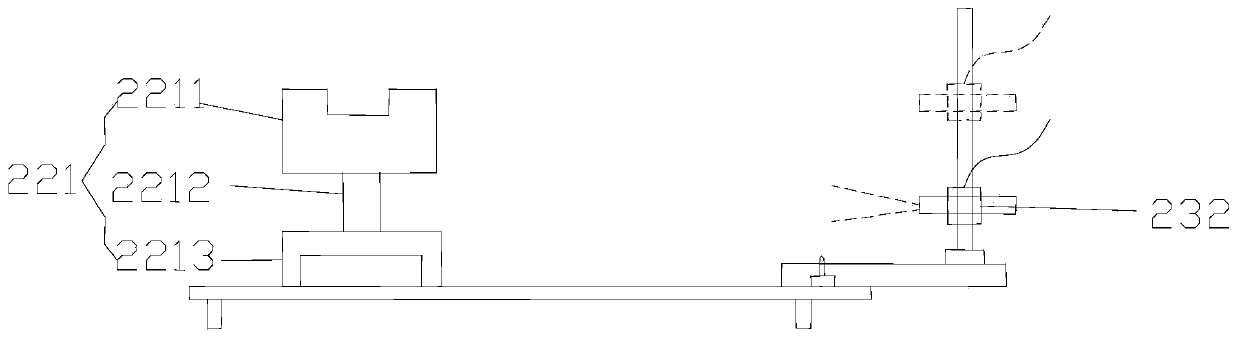

Method used

Image

Examples

Embodiment 1

[0066] In this embodiment, the above-mentioned determination of the actual equivalent value is carried out on the water, and the final equivalent value is determined, that is, the distance between the camera and the object to be measured is determined, and the distance is kept constant, and the test platform is placed underwater. The influence of the underwater environment on the measurement results of the nuclear fuel height is tested. Since the influence of the above-water and underwater environments on the equivalent value is small, the influence of the environment on the equivalent value is not considered here.

[0067] Further, Table 2 and Table 3 represent the measurement results of the height difference between the upper and lower tube bases above water and underwater, respectively. The water medium here is ordinary natural water. Fix the distance between the above-water and underwater camera devices and the target, adjust the test platform to the best state, measure th...

Embodiment 2

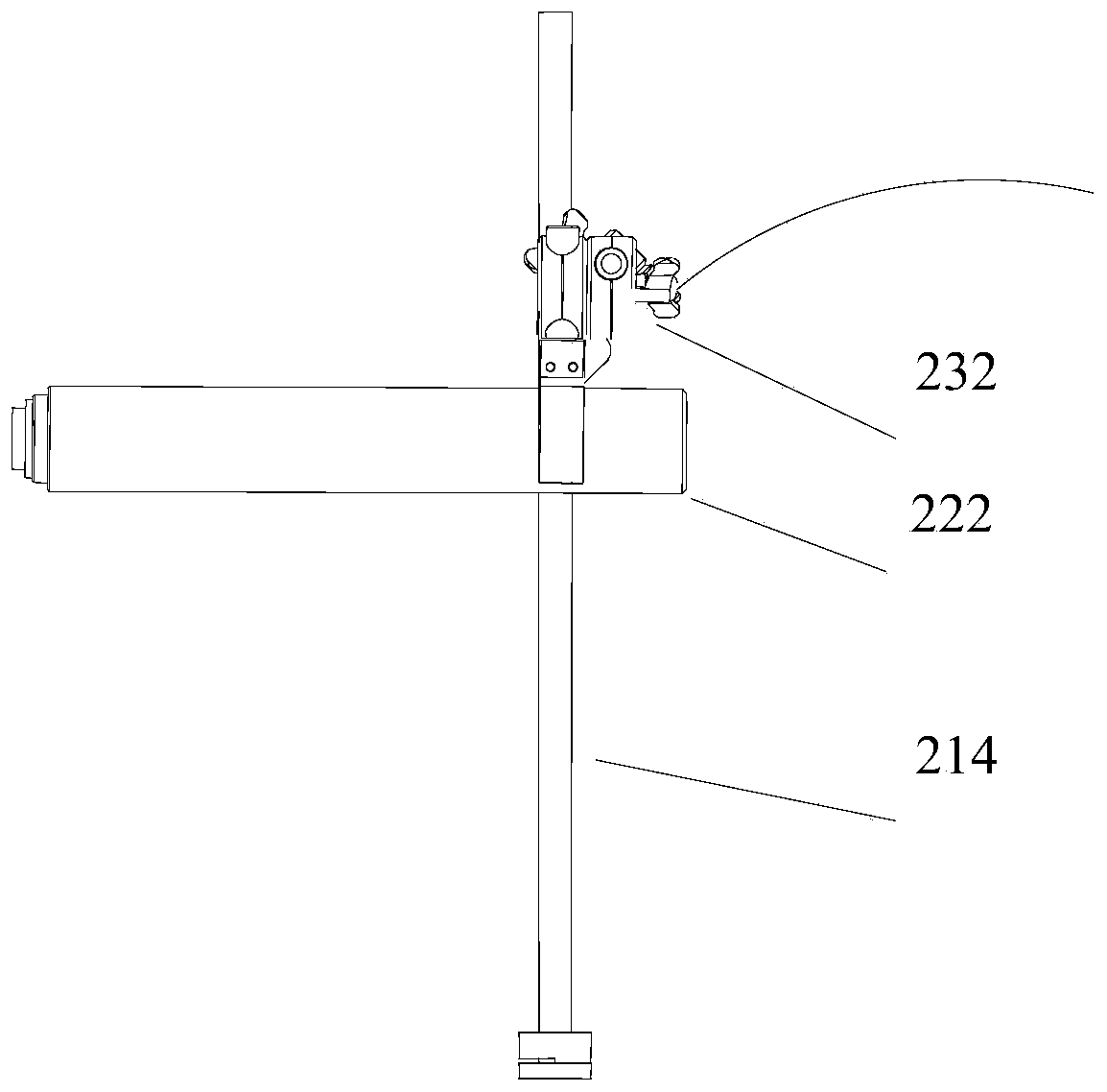

[0076] In this embodiment, the mirror imaging principle is used to conduct an indirect imaging test on the target sample, and to verify the measurement accuracy. Preferably, in this test, the width of the upper nozzle of the nuclear fuel assembly is measured for the above-water and underwater conditions respectively. Move the slider to the upper end of the camera bracket, then fix it with the fixing device, and shoot the light from the camera on the reflector to make the light reflector present an object image. If the reflector does not present a full phase, you can use the second drive Components make it appear full phase in the mirror. Table 4 and Table 5 show the measurement results of the width of the upper pipe seat above water and underwater respectively. It can be seen from the comparison that the measurement results of the mirror imaging model and the direct illumination model are closer. Therefore, the mirror imaging model is the premise of enhancing the service life ...

Embodiment 3

[0082] In this embodiment, the nuclear fuel assembly test platform can also measure the integrity of the appearance of the nuclear fuel assembly. By creating defects on the surface of nuclear fuel assemblies such as roll marks, scratches, sticking, rusting (see Figures 5a to 5d ), reasonable selection of the camera device, artificial adjustment of the parameters of the camera device, and the cleaning image of the target object can be taken to realize the integrity detection of the target object surface. If the surface integrity of the target object is damaged, it can be detected by the camera probe and the defect site can be marked by software. From Figures 5a to 5d It can be clearly seen that the sample defects can be clearly detected, realizing the possibility that the test platform can detect the integrity of the appearance of defects underwater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com