A carbon fiber heat exchanger and its manufacturing process

A heat exchanger and carbon fiber technology, applied in the field of heat exchange, can solve the problems of low conduction efficiency, high cost of metal titanium, and short service life of heat exchangers made of non-metallic polymer materials, so as to improve adaptability, service life, and preparation The method is simple and the effect of increasing the profit of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

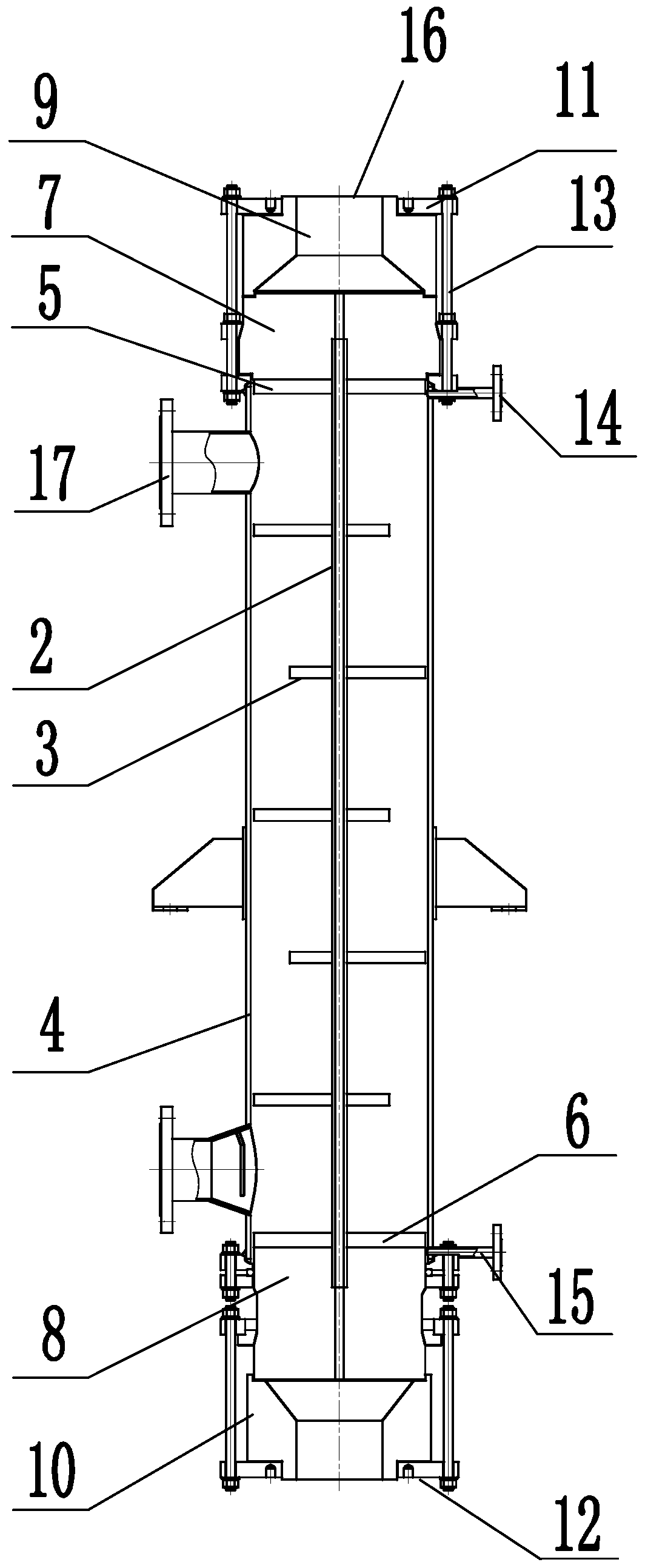

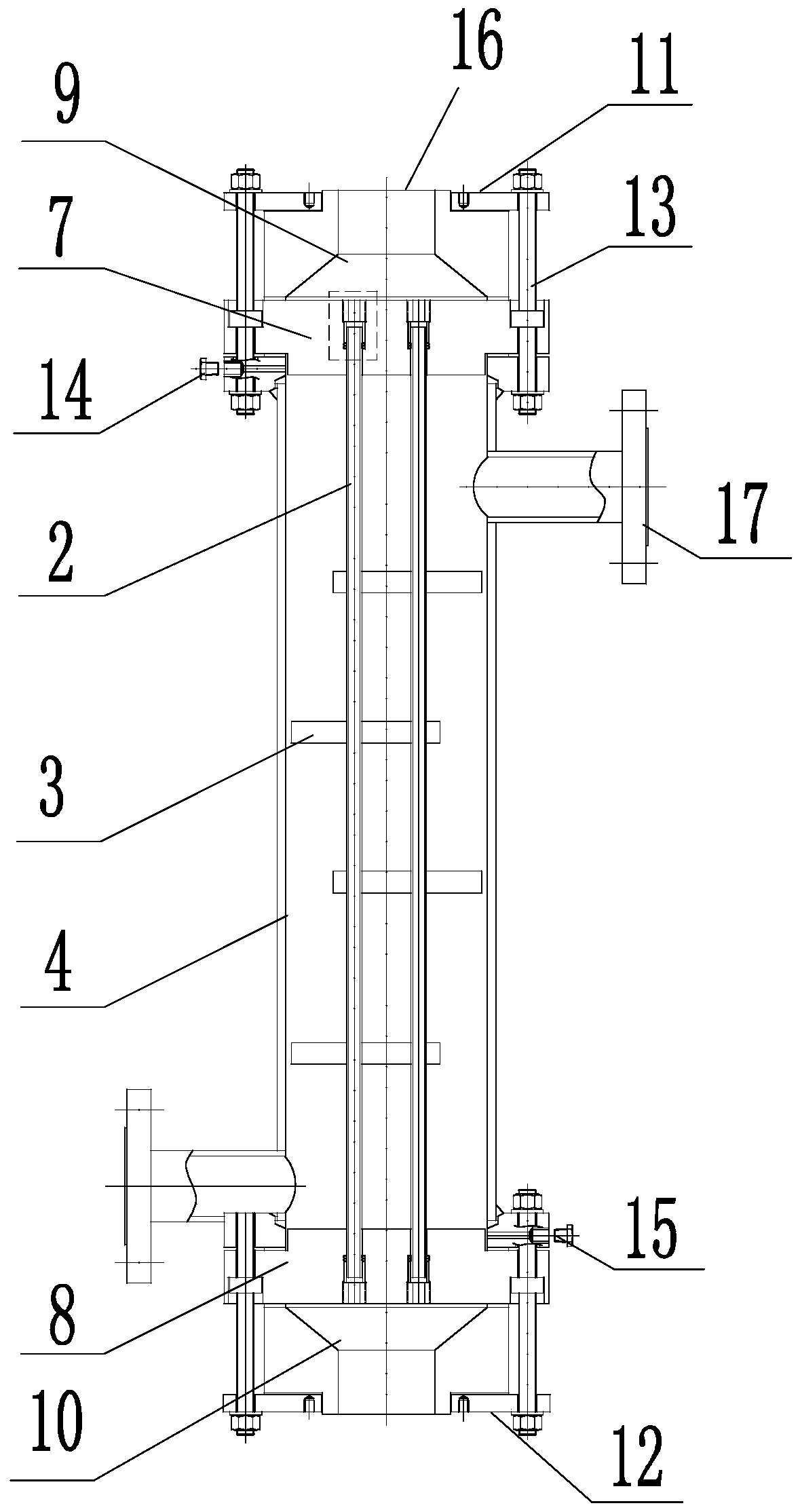

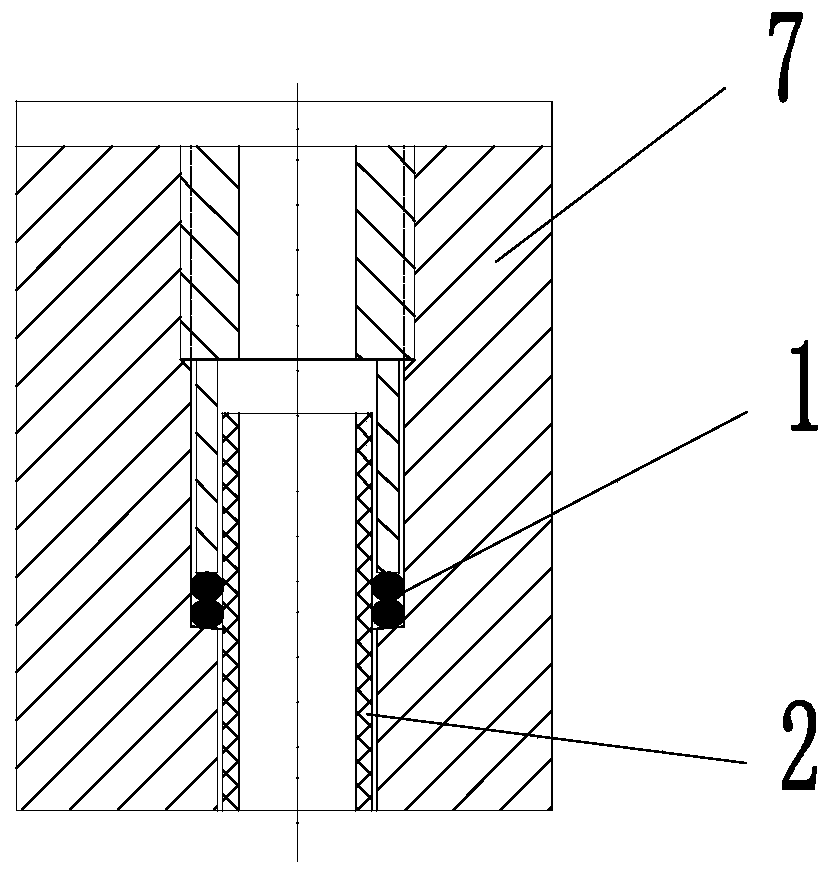

[0025] Such as Figure 1~3 As shown, a novel carbon fiber heat exchanger includes a jacket 4, which also includes a carbon fiber heat exchange tube 2, a baffle 3, an upper tube sheet 7, and a lower tube sheet 8; the inner cavity of the jacket 4 is vertically A plurality of carbon fiber heat exchange tubes 2 are provided; the carbon fiber heat exchange tubes 2 are distributed along the axis of the jacket 4 in an equilateral triangle or square;

[0026] There are multiple baffles 3, and the multiple baffles are distributed in the inner cavity of the jacket 4 from top to bottom; the adjacent baffles 3 are arranged in a staggered left and right order to increase the residence time of the shell-side fluid. And the distance between the baffles 3 can be adjusted, so as to control the flow rate more effectively and improve the heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com