Preparation method of laser-modified self-healing thermal barrier coating based on ultrasonic vibration assistance

A technology of thermal barrier coating and ultrasonic vibration, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., to achieve the effect of improving adaptability and service life, improving thermal shock resistance and thermal corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

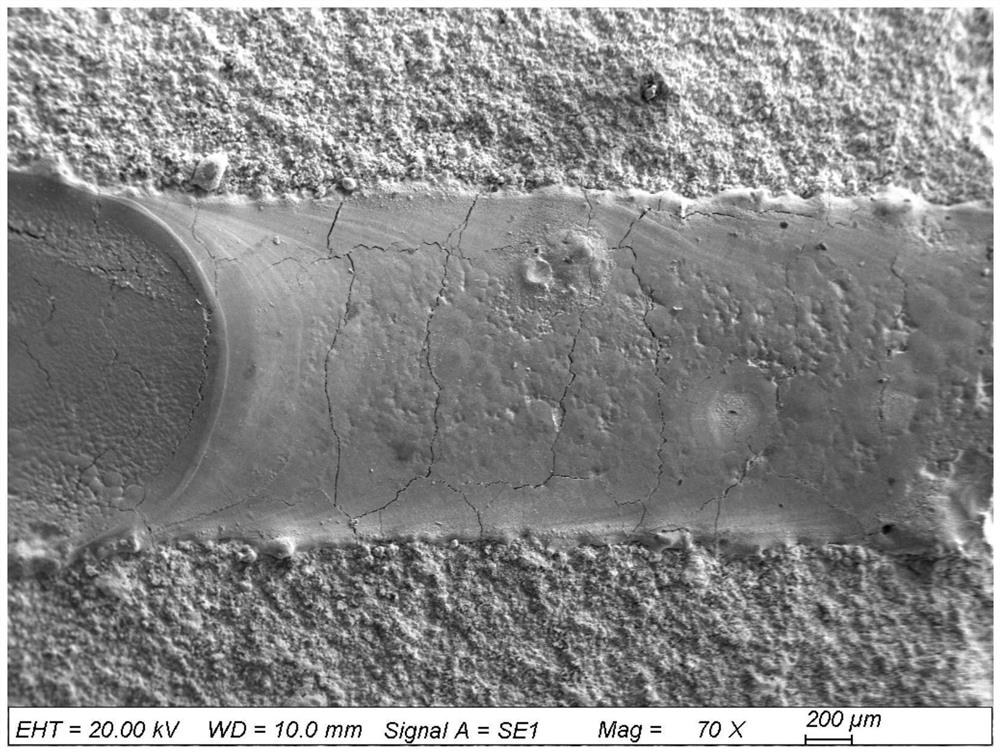

[0027] 1) Prepare a thermal barrier coating on a nickel-based superalloy substrate, including a ceramic layer and an adhesive layer; prepare an adhesive layer by supersonic flame spraying, the powder is NiCrAlY, and the thickness of the adhesive layer is about 100 μm.

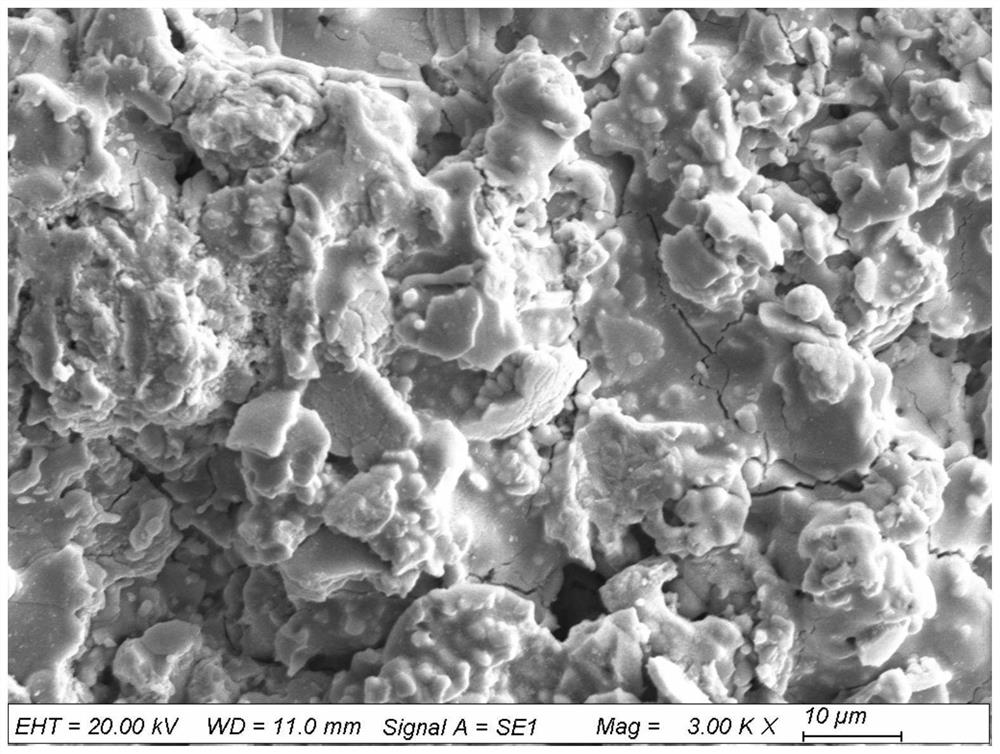

[0028] 2) On the prepared bonding layer, a ceramic layer is prepared by atmospheric plasma spraying (APS), the powder is 7% yttria partially stabilized zirconia (7YSZ), and the thickness of the ceramic layer is about 300 μm.

[0029] 3) Ultrasonic cleaning is performed on the prepared thermal barrier coating to remove surface stains and impurities.

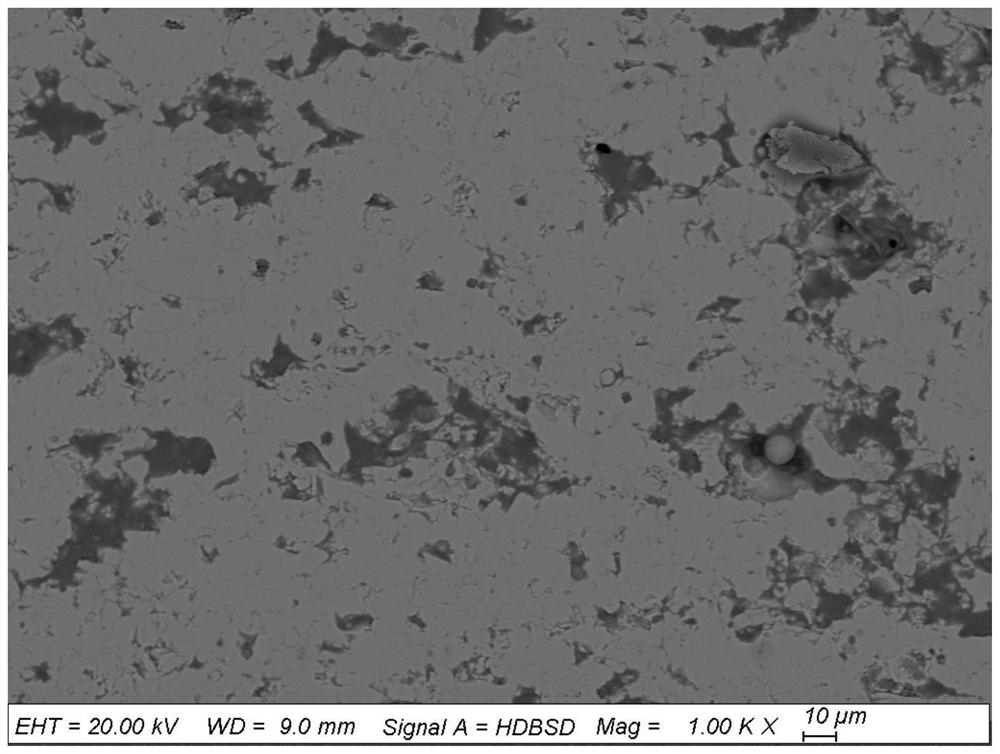

[0030] 4) 5% TiAl 3 +CYSZ self-healing powder is evenly spread on the thermal barrier coating sample with a powder thickness of about 0.3mm. Laser modification technology (laser alloying) is used to modify the ceramic layer of the thermal barrier coating. The selected The equipment is a 1kW flexible laser manufacturing system and ultrasonic vibration auxiliary equ...

Embodiment 2

[0038] 1) Prepare a thermal barrier coating on a nickel-based superalloy substrate, including a ceramic layer and an adhesive layer; use atmospheric plasma spraying (APS) to prepare an adhesive layer, the powder is NiCrAlY, and the thickness of the adhesive layer is about 100 μm.

[0039] 2) On the prepared adhesive layer, a ceramic layer is prepared by atmospheric plasma spraying (APS), the powder is 7% yttria partially stabilized zirconia (7YSZ), and the thickness of the ceramic layer is about 300 μm.

[0040] 3) Ultrasonic cleaning is performed on the prepared thermal barrier coating to remove surface stains and impurities.

[0041] 4) 10% TiAl 3 +CYSZ self-healing powder is evenly spread on the surface of the thermal barrier coating sample, and the thickness of the powder is about 0.4mm. The laser modification technology (laser alloying) is used to modify the ceramic layer of the thermal barrier coating. The equipment is a 1kW flexible laser manufacturing system. The lase...

Embodiment 3

[0044] 1) Prepare a thermal barrier coating on a nickel-based superalloy substrate, including a ceramic layer and an adhesive layer; prepare an adhesive layer by atmospheric plasma spraying, the powder is NiCrAlY, and the thickness of the adhesive layer is about 100 μm.

[0045] 2) On the prepared adhesive layer, a ceramic layer is prepared by atmospheric plasma spraying (APS), the powder is 7% yttria partially stabilized zirconia (7YSZ), and the thickness of the ceramic layer is about 300 μm.

[0046] 3) Ultrasonic cleaning is performed on the prepared thermal barrier coating to remove surface stains and impurities.

[0047] 4) 15% TiAl 3 +CYSZ self-healing powder is evenly spread on the surface of the thermal barrier coating sample, and the thickness of the powder is about 0.5mm. The laser modification technology (laser alloying) is used to modify the ceramic layer on the surface of the thermal barrier coating. The equipment used is a 1kW flexible laser manufacturing system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com