Nitrogen and phosphorus co-doped porous carbon film @ polyaniline hybrid electrode material having interface covalent bond link, and preparation method of hybrid electrode material

A hybrid material, porous carbon technology, applied in the field of materials, can solve the problem of inappropriate porous carbon, and achieve the effects of improving specific capacitance, improving cycle stability, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a polyaniline-porous carbon composite material with interfacial covalent bonds, comprising the following steps:

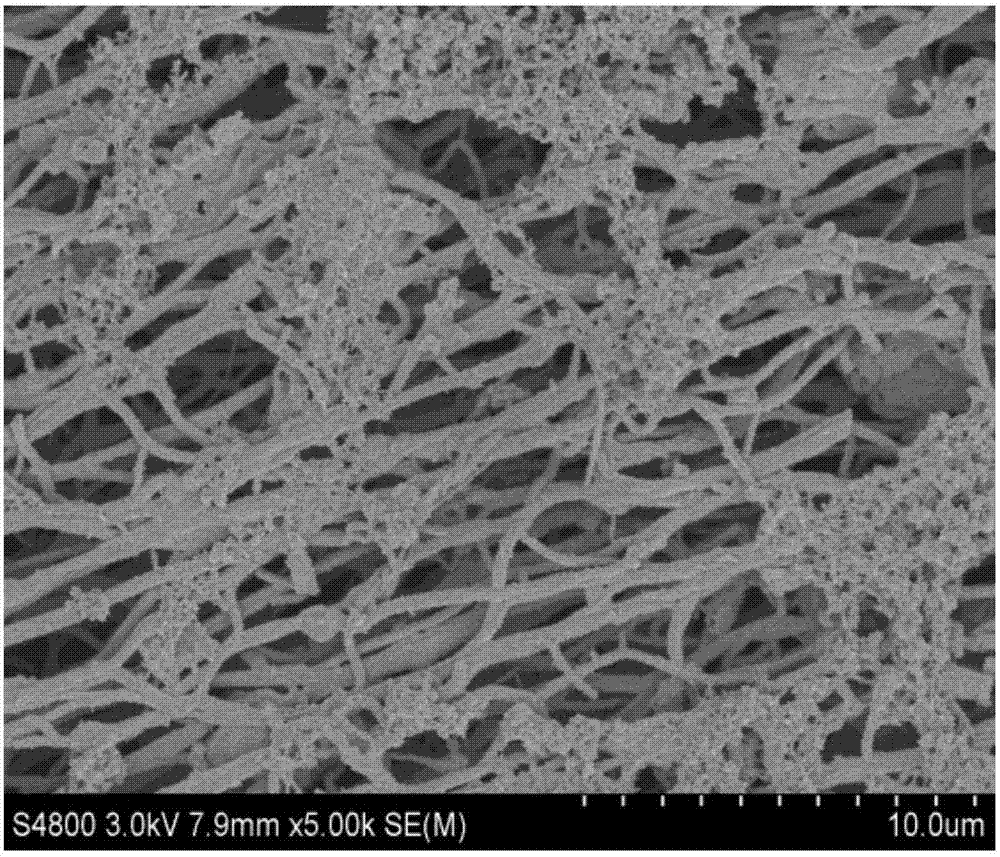

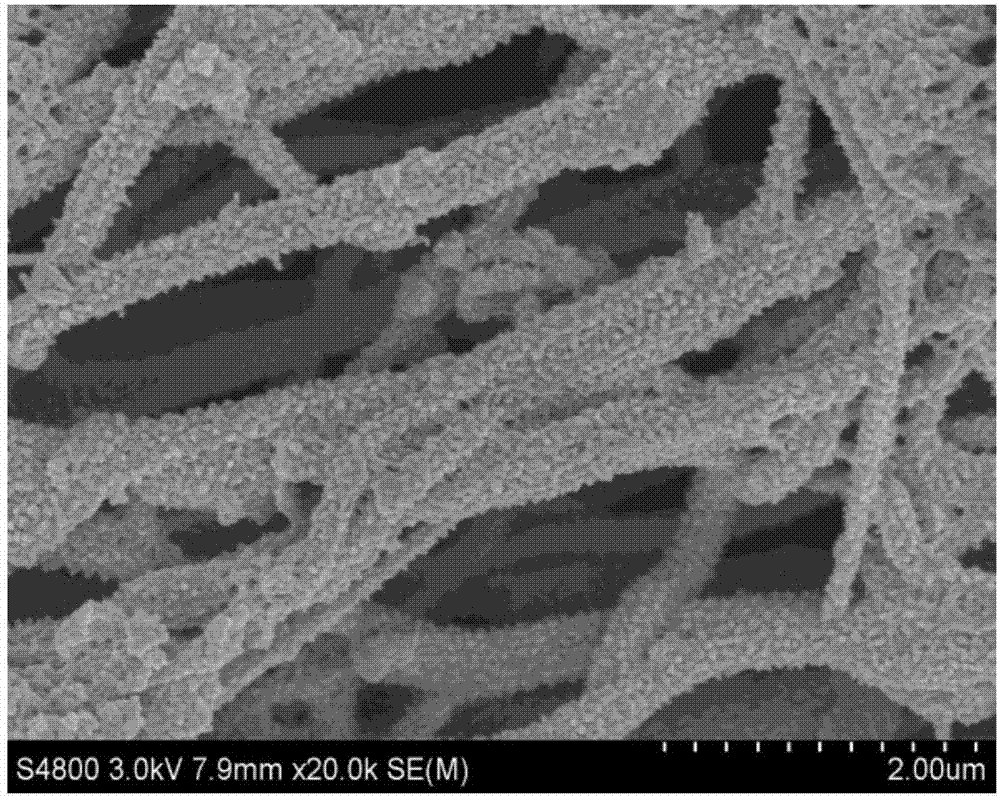

[0050] (1) Weighing the mass ratio of polyacrylonitrile: triphenylphosphine: SBA-15 is 2 grams: 1 grams: 1 grams, with 21 grams of N,N-dimethylformamide as solvent, in 70 ° C oil bath Next, dissolve polyacrylonitrile, triphenylphosphine and SBA-15 in N,N-dimethylformamide (DMF), and stir continuously at 300r / min for 8h with a magnetic stirrer to fully dissolve and mix the mixed system. homogeneous, and then ultrasonicated with 200W for 0.5h to obtain a mixed spinning solution with a mass content of 8% polyacrylonitrile. The nanofiber membrane was obtained by electrospinning (the distance between the center of the drum and the spinning needle was 15cm, the drum was φ8.5×16cm, the needle was No. 20, the needle size was φ0.06mm, the voltage was 25kv, and the rotating speed was 750r / min). Then, nitrogen and phosphorus co-doped porous carb...

Embodiment 2

[0076] (1) Weighing the mass ratio of polyacrylonitrile: triphenylphosphine: SBA-15 is 2.5 grams: 1 gram: 1 gram in turn, with 22 grams of N, N-dimethylformamide as solvent, at 70 ℃ oil Under the bath, dissolve in N,N-dimethylformamide (DMF), stir continuously with a magnetic stirrer at 300r / min for 8h, fully dissolve the mixed system and mix evenly, and then use a 200W ultrasonic wave for 0.5h to obtain A mixed spinning solution with a polyacrylonitrile content of 8%. The nanofiber membrane was obtained by electrospinning (the distance between the center of the drum and the spinning needle was 15cm, the drum was φ8.5×16cm, the needle was No. 20, the needle size was φ0.06mm, the voltage was 25kv, and the rotating speed was 750r / min). Then pre-oxidize, carbonize, activate and etch (soak in 20% hydrofluoric acid for 24 hours), etc. to obtain nitrogen and phosphorus co-doped porous carbon membrane.

[0077] Pre-oxidation: In air atmosphere, increase the temperature at 1°C / min to...

Embodiment 3

[0086](1) Weighing the mass ratio of polyacrylonitrile: triphenylphosphine: SBA-15 is 2 grams: 1 gram: 1 gram in turn, with 21 grams of N,N-dimethylformamide as solvent, at 70 ℃ oil Under the bath, dissolve in N,N-dimethylformamide (DMF), stir continuously with a magnetic stirrer at 300r / min for 8h, fully dissolve the mixed system and mix evenly, and then use a 200W ultrasonic wave for 0.5h to obtain A mixed spinning solution with a polyacrylonitrile content of 8%. Nanofiber membranes were obtained by electrospinning (the distance between the center of the drum and the spinning needle was 15cm, the drum was φ8.5×16cm, the needle was No. 20, the needle size was Φ0.06mm, the voltage was 25kv, and the rotation speed was 750r / min). Then pre-oxidize, carbonize, activate and etch (soak in 20% hydrofluoric acid for 24 hours), etc. to obtain nitrogen and phosphorus co-doped porous carbon membrane.

[0087] Pre-oxidation: In air atmosphere, increase the temperature at 1°C / min to 280°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com