Method and equipment for impurity removal and enrichment of valuable metal zinc through zinc hypoxide

A valuable metal, secondary zinc oxide technology, applied in the direction of improving process efficiency, can solve the problems of environmental pollution, resource waste, fluoride and other impurities, and achieve obvious cost advantages, high output efficiency, and impurity removal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution will be described in detail below in conjunction with specific embodiments.

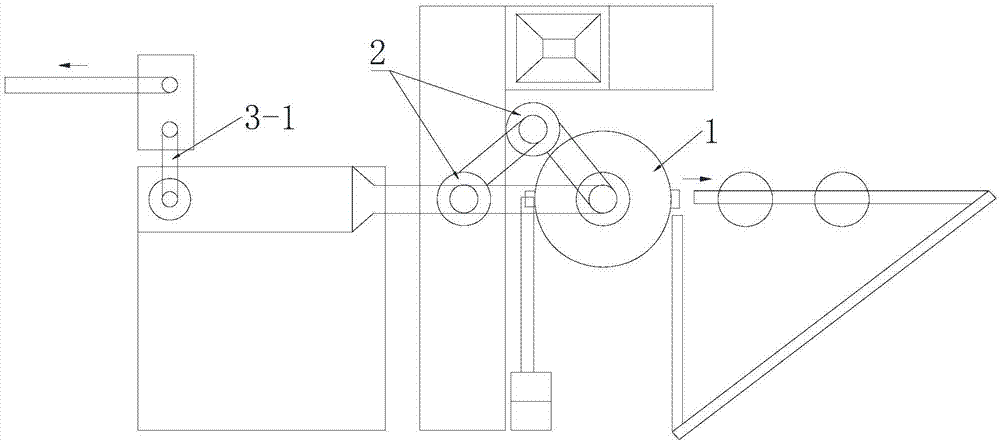

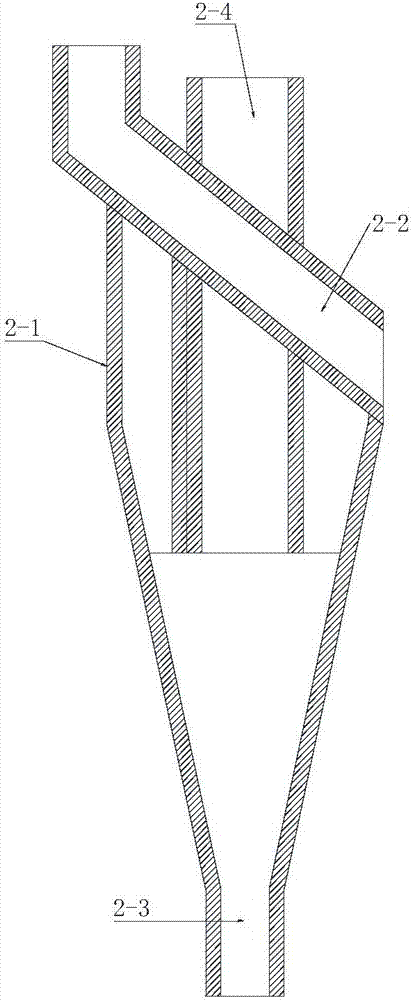

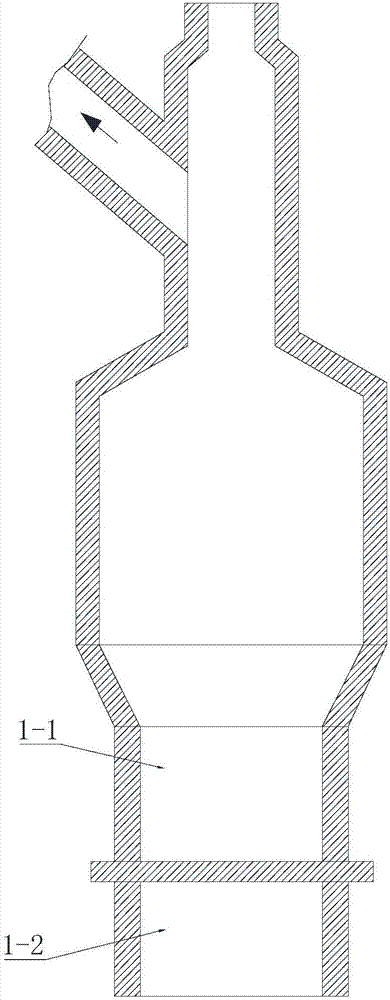

[0045] Such as Figure 1-Figure 7 As shown, the present invention is a method for removing impurities and enriching valuable metal zinc with secondary zinc oxide, which includes a roasting section and a purification section, and the roasting section is to send the soot raw material containing high fluorine chlorine suboxide zinc oxide into a fluidized bed furnace for roasting and decarburization Impurity removal enrichment recovery zinc oxide. During the roasting process of the fluidized furnace in the roasting section, oxygen is supplemented by a blower to fully burn the carbon, metal zinc particles and oxygen in the raw materials, and the high-quality zinc oxide calcine after sintering, impurity removal and enrichment is discharged from the fluidized furnace slag discharge drum , the carbon dioxide, water vapor, chloride and a small amount of zinc oxide dust generated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com