Insulation oil vacuum adsorption regeneration comprehensive treatment system and application thereof

A vacuum adsorption and comprehensive treatment technology, applied in the direction of lubricating compositions, etc., can solve the problems of reduced removal efficiency and reduced use efficiency of adsorbents, and achieve the effects of saving power outage time, improving use efficiency, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

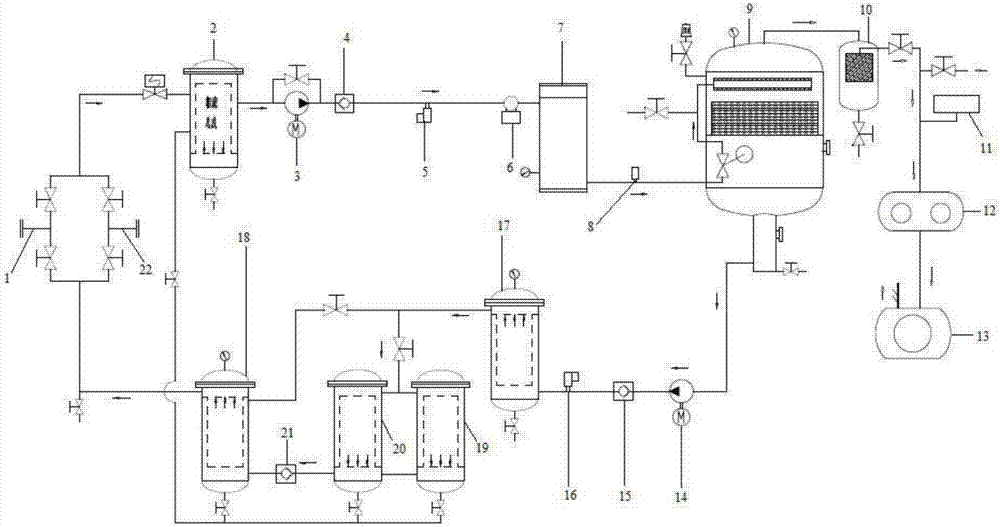

[0072] Carried out insulating oil regeneration treatment for a 110kV TBEA SFZ8-31500 / 110 transformer. According to on-site records, the oil weighs 16.3 tons, the total corrosive sulfur is 21.3mg / kg, the dissolved copper content is 1.8mg / kg, and the dielectric loss of the oil is 2.4 %,

[0073] The insulating oil to be treated is input from the oil inlet 1, flows through the primary filter tank 2, and is heated to 80°C by the heater 7, and the heated oil is input into the vacuum separator 8 for gas-liquid separation; the oil after gas-liquid separation The product is successively absorbed by the fine filter 17, the parallel regenerative filter, and the fine filter 18; finally, it flows back to the insulating oil equipment through the oil outlet 22.

[0074] The pore diameter of the filled filter element of the primary filter tank 2 is 20-100 μm.

[0075] The degree of vacuum in the vacuum separator 8 is less than or equal to 100Pa.

[0076] The pore size of the precision filt...

Embodiment 2

[0082] Compared with Example 1, the difference is that the heater 7 heats up to 50°C. After 3 days of circulation, the total corrosive sulfur content is 18.5mg / kg, the dissolved copper content is 0.6mg / kg, and the oil dielectric loss is 0.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com