Method for constructing spinel structure on surface layer of lithium-rich manganese-based positive electrode material

A spinel structure and positive electrode material technology, applied in the direction of positive electrodes, structural parts, chemical instruments and methods, etc., can solve the problems of low Coulombic efficiency, achieve the effects of simple regulation, easy expansion of production, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] After adding 5g of lithium-rich manganese-based positive electrode material to 100mL aqueous solution of ammonium dihydrogen phosphate with a concentration of 0.25mol / L, magnetic stirring is performed to make the electrode material generate Li in the acidic solution. + —H +Ion exchange, and measure the pH value of the ammonium dihydrogen phosphate aqueous solution with a pH meter until the change rate of the pH value is less than 0.01min -1 , carry out vacuum filtration, and wash the solid obtained by suction filtration with deionized water for 3 times, and then dry in an oven at 80°C for 6h; then place the dried solid in a muffle furnace, and sinter at 450°C for 5h Transform the lithium-deficient structure of the surface layer into a spinel structure, and cool with the furnace to obtain a lithium-rich manganese-based positive electrode material with a spinel structure on the surface.

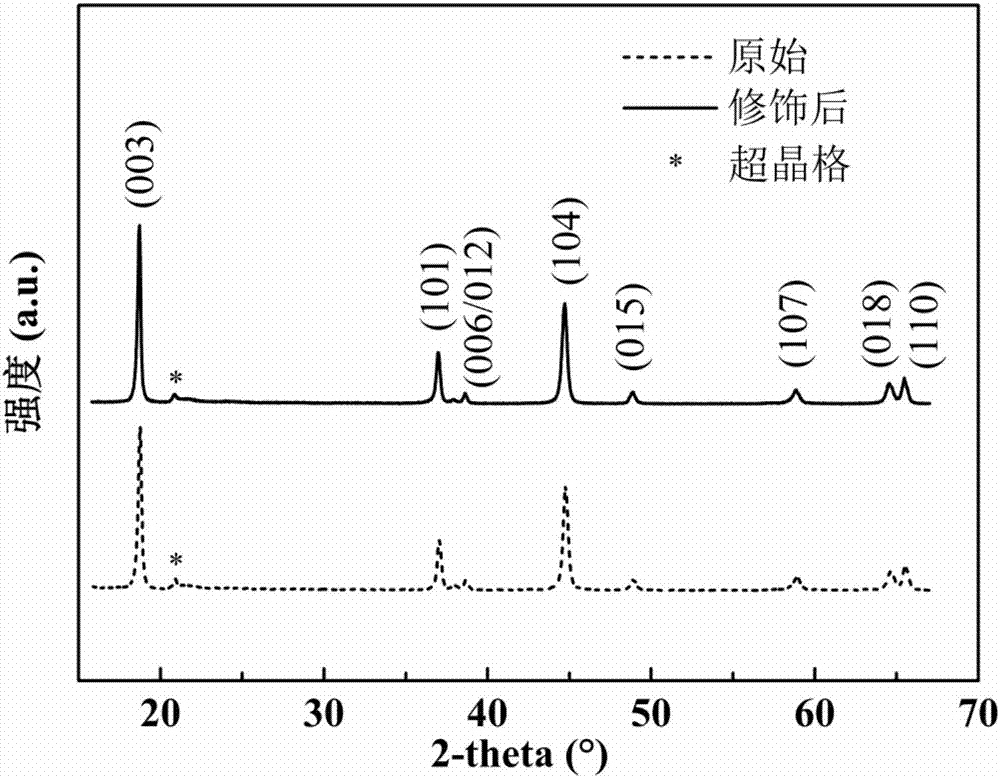

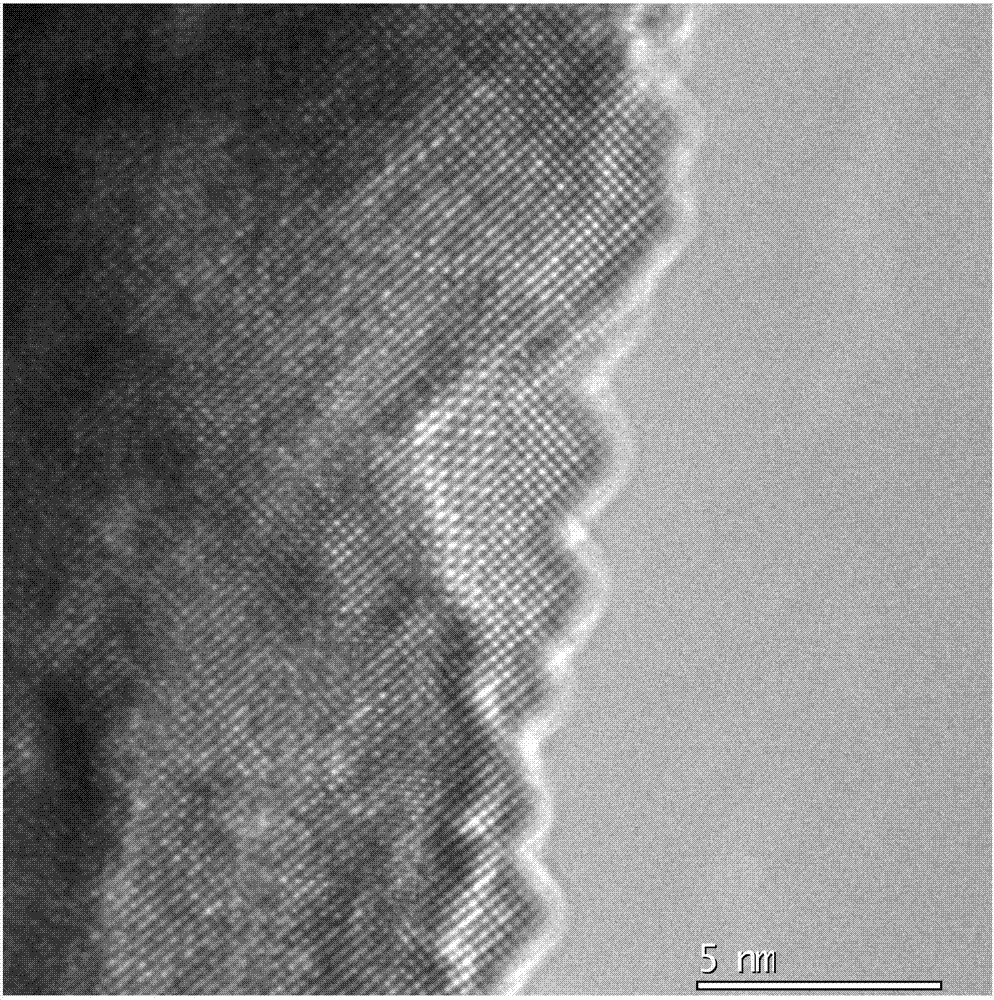

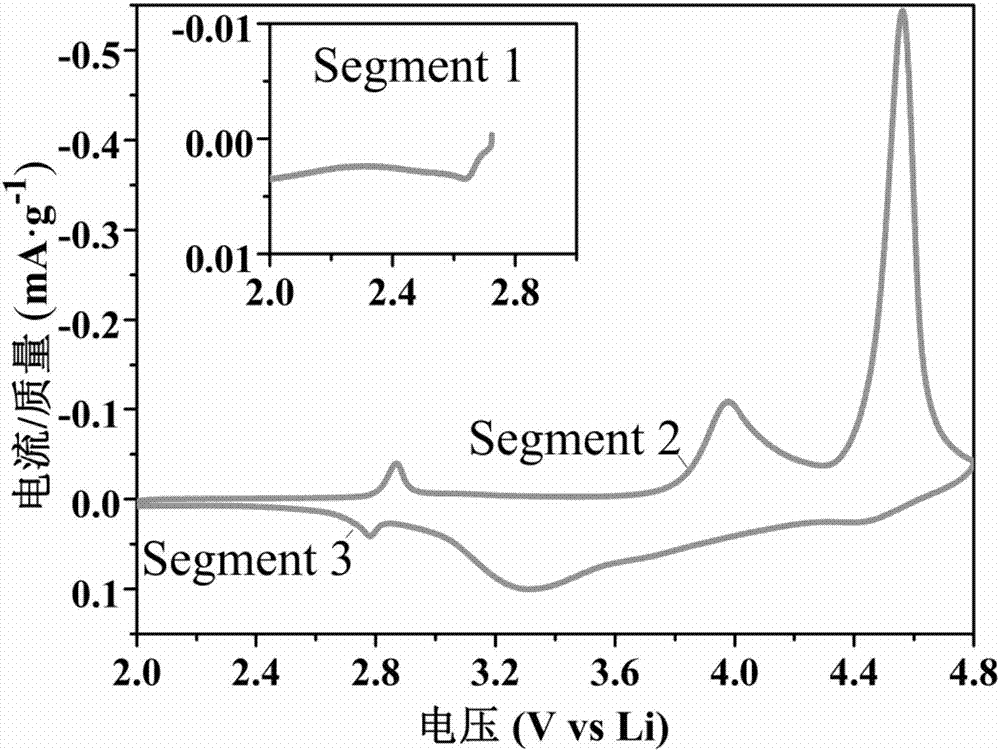

[0036] figure 1 It is the XRD comparison chart of the modified lithium-rich mangan...

Embodiment 2

[0040] After adding 5g of lithium-rich manganese-based positive electrode material to 100mL aqueous solution of ammonium dihydrogen phosphate with a concentration of 0.25mol / L, magnetic stirring is performed to make the electrode material generate Li in the acidic solution. + —H + Ion exchange, and measure the pH value of the ammonium dihydrogen phosphate aqueous solution with a pH meter until the change rate of the pH value is less than 0.01min -1 , carry out vacuum filtration, and wash the solid obtained by suction filtration with deionized water for 3 times, and then dry in an oven at 80°C for 6h; then place the dried solid in a muffle furnace, and sinter at 300°C for 5h Transform the lithium-deficient structure of the surface layer into a spinel structure, and cool with the furnace to obtain a lithium-rich manganese-based positive electrode material with a spinel structure on the surface.

[0041] Compared with the XRD pattern of the original lithium-rich manganese-based ...

Embodiment 3

[0045] After adding 5g of lithium-rich manganese-based positive electrode material to 100mL aqueous solution of ammonium dihydrogen phosphate with a concentration of 0.25mol / L, magnetic stirring is performed to make the electrode material generate Li in the acidic solution. + —H + Ion exchange, and measure the pH value of the ammonium dihydrogen phosphate aqueous solution with a pH meter until the change rate of the pH value is less than 0.01min -1 , carry out vacuum filtration, and wash the solid obtained by suction filtration with deionized water for 3 times, and then dry in an oven at 80°C for 6h; then place the dried solid in a muffle furnace, and sinter at 600°C for 5h Transform the lithium-deficient structure of the surface layer into a spinel structure, and cool with the furnace to obtain a lithium-rich manganese-based positive electrode material with a spinel structure on the surface.

[0046] Compared with the XRD pattern of the original lithium-rich manganese-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com