Support frame for pellicles

A technology of supporting frame and skin, which is applied in the direction of originals, optics, instruments, etc. used for photomechanical processing, can solve the problems of circuit pattern offset and other problems, and achieve the effect of reducing processing amount, reducing processing amount, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

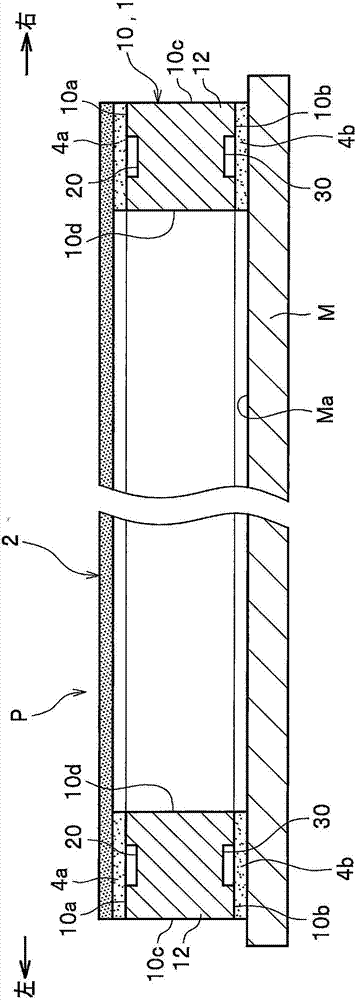

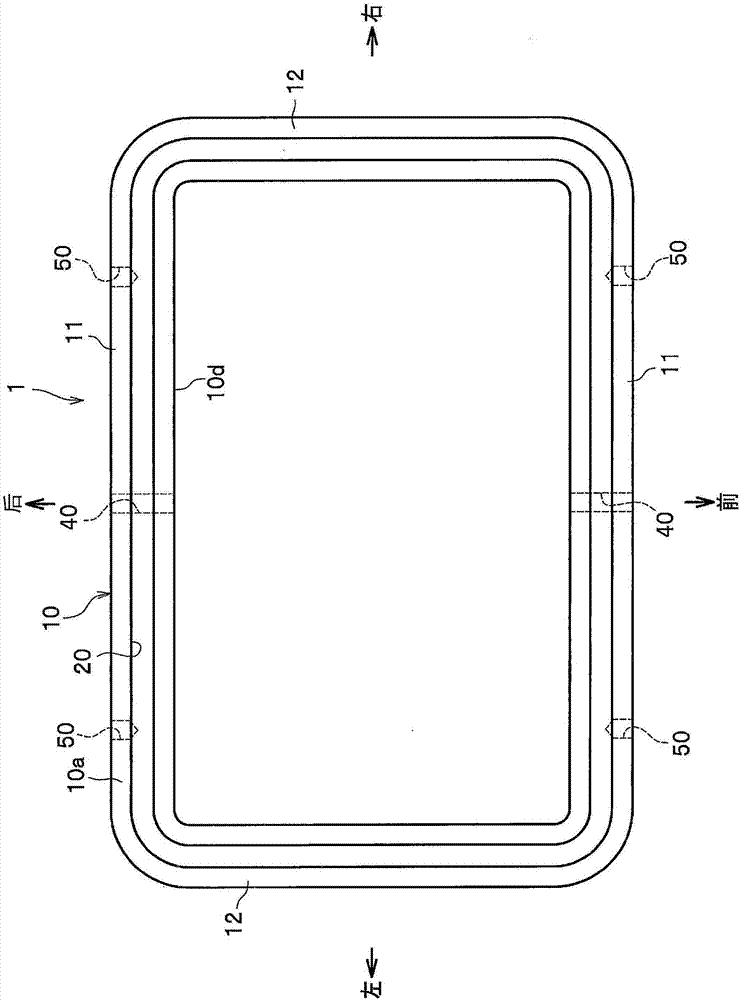

[0038] Embodiments of the present invention will be described in detail with reference to the drawings as appropriate.

[0039] In addition, in each drawing of this embodiment, in order to demonstrate the structure of a support frame easily, each part of a support frame is shown schematically moderately.

[0040] In the following description, front, rear, left, right, front, and back are set for easy understanding of the support frame, and do not limit the structure and use state of the support frame.

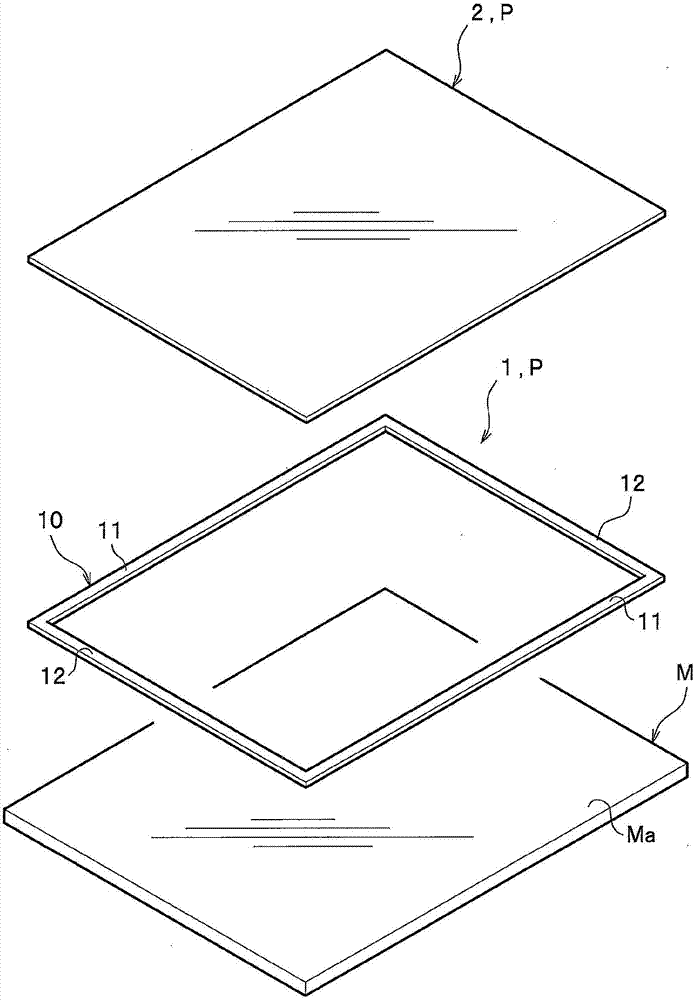

[0041] like figure 1 As shown, the support frame 1 of this embodiment is a member used for the skin P used in the manufacturing process of an integrated circuit. The skin P is a dustproof cover for preventing dust and the like from adhering to the front surface Ma of the transparent substrate M (photomask).

[0042] The skin P includes: a supporting frame 1 that surrounds the entire circuit pattern (not shown) drawn on the transparent substrate M; and a skin coating 2 that co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com