Method of manufacturing trim

A manufacturing method and decorative strip technology, applied in metal rolling, metal rolling, sealing devices, etc., can solve problems such as waste and poor yield, and achieve the effects of reducing deviation, ensuring rigidity, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] Next, an embodiment in which a mode for carrying out the present invention has been embodied will be described.

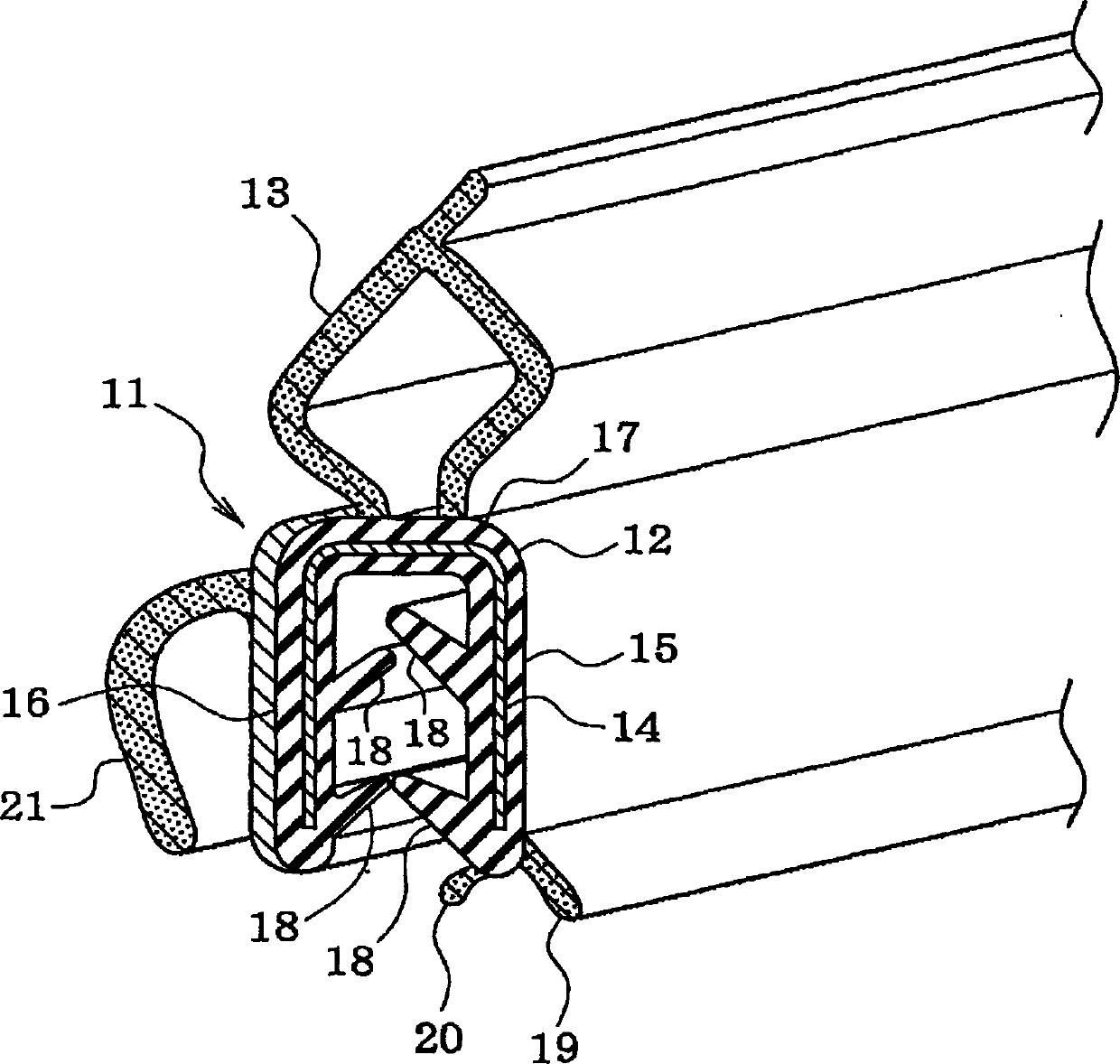

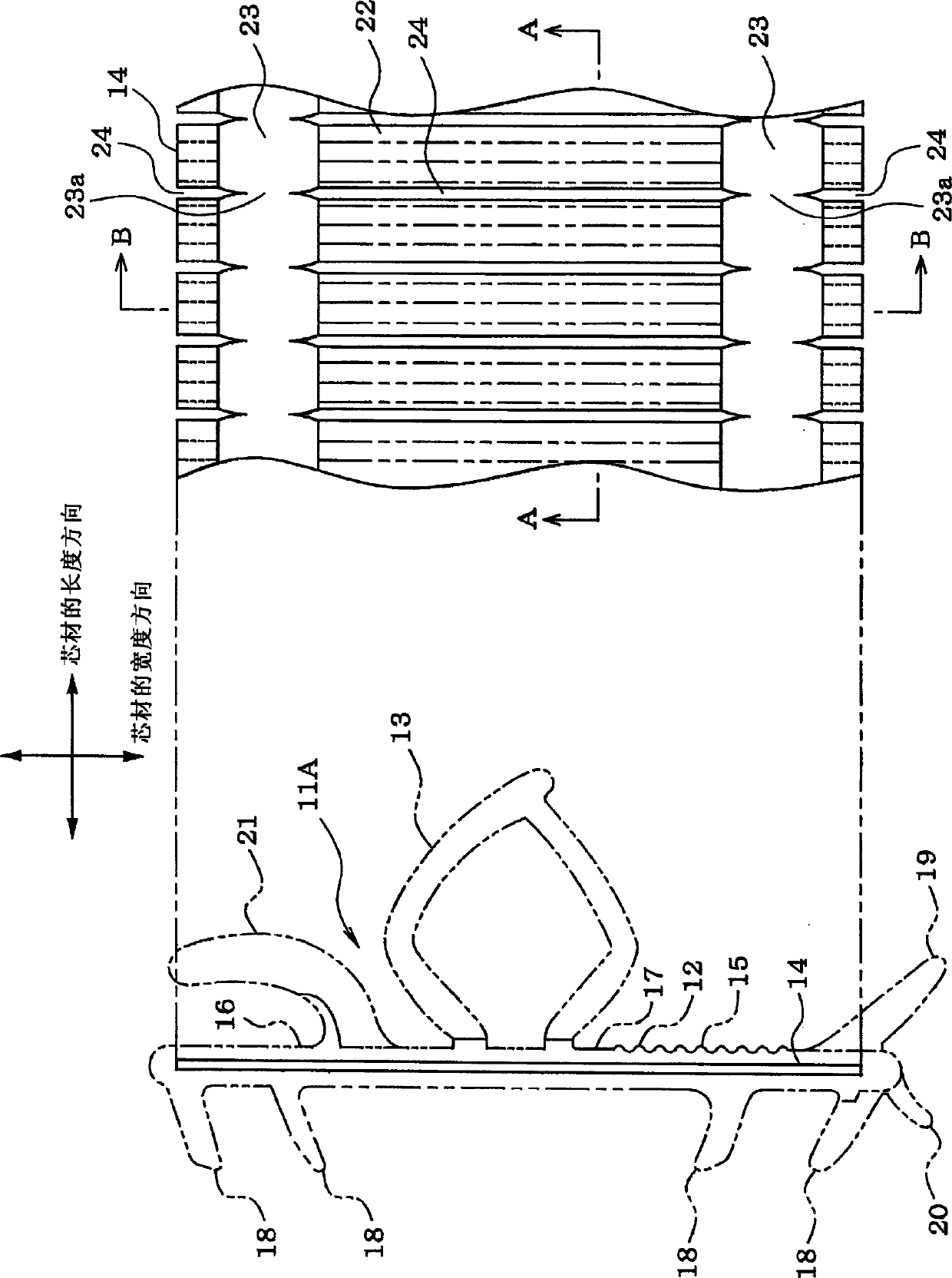

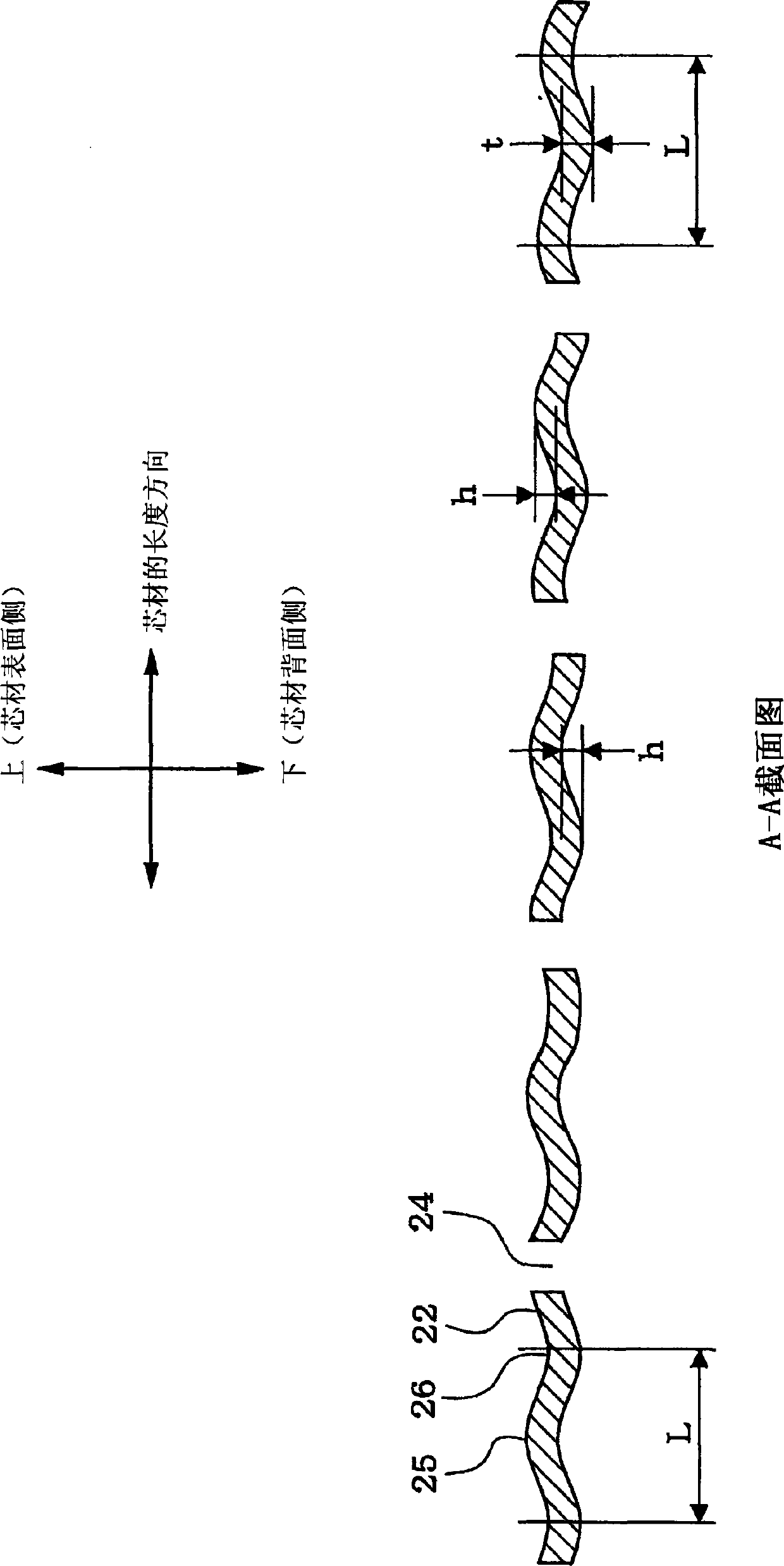

[0079] Such as figure 1 As shown, with regard to the long trim 11 (so-called trunk sealing trim) installed on the flange (not shown) of the trunk opening edge of the body panel of the automobile or the like, rubber or thermoplastic synthetic resin (including Thermoplastic Elastomer) and other elastic polymer materials are extruded to integrally form the mounting part 12 with a U-shaped cross-section and the cylindrical hollow sealing part 13 made of sponge rubber or soft TPE material, and then insert and extrude Molding (also referred to as co-extrusion molding) embeds the core material 14 formed of a band-shaped metal plate in the mounting portion 12 .

[0080] The mounting portion 12 has a vehicle exterior side wall portion 15, a vehicle interior side wall portion 16, and a bottom wall portion 17 connecting the two side wall portions 15 and 16. On the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com