Thermal superconducting heat dissipation component and manufacturing method thereof

A technology for a heat dissipation component and a manufacturing method, which is applied in the field of heat transfer, can solve the problem that an aluminum heat sink cannot meet the heat dissipation requirements of a high heat flux density and a high power module, and achieves the effects of being suitable for mass production, reducing production costs, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

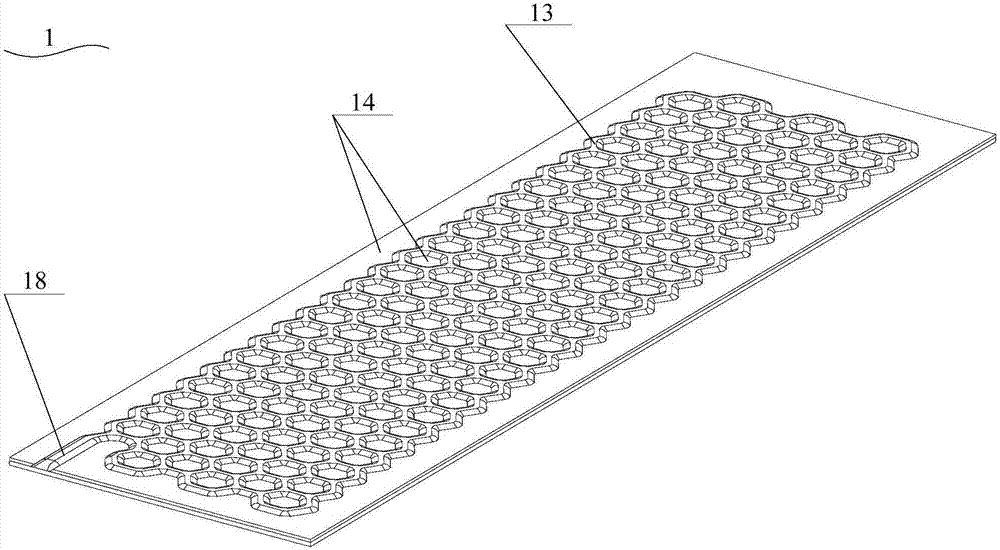

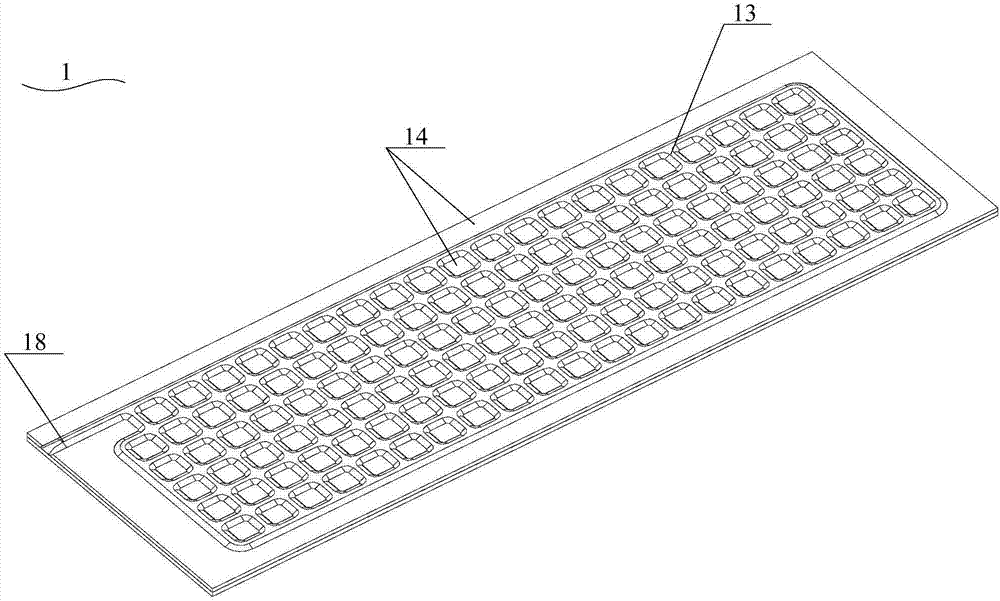

[0080] see Figure 1 to Figure 11 , the present invention provides a thermal superconducting heat dissipation assembly, the thermal superconducting heat dissipation assembly includes: a thermal superconducting heat dissipation plate 1, a thermal superconducting circuit 13 is formed in the thermal superconducting heat dissipation plate 1, and the thermal superconducting conduit The road 13 is a closed pipeline, and the thermal superconducting pipeline 13 is filled with a heat transfer working medium (not shown); a heat dissipation fin plate structure 2, and the heat dissipation fin plate structure 2 is located on the thermal superconducting heat dissipation plate 1; the heat dissipation fin plate structure 2 includes at least one heat dissipation fin 21 extending in a wave shape along a direction parallel to the surface of the thermal superconducting heat dissipation plate 1; specifically, the heat dissipation fin 21 can be It extends in a wave shape along the length direction ...

Embodiment 2

[0097] see Figure 12 and Figure 13 , this embodiment also provides a thermal superconducting heat dissipation assembly, the structure of the thermal superconducting assembly described in this embodiment is roughly the same as that of the thermal superconducting heat dissipation assembly described in Embodiment 1, the difference between the two is : In Embodiment 1, the heat dissipation fin plate structure 2 includes a first heat dissipation fin plate 22, and the first heat dissipation fin plate 22 is composed of one heat dissipation fin 21; and in the present embodiment, the heat dissipation fin plate The heat dissipation fin plate structure 2 includes a second heat dissipation fin plate 23, and the second heat dissipation fin plate 23 includes a plurality of heat dissipation fins 21 and connecting parts 231 located at both ends of the heat dissipation fins 21; The heat dissipation fins 21 are arranged in parallel and at intervals, and the connecting portion 231 is integral...

Embodiment 3

[0101] This embodiment also provides a thermal superconducting heat dissipation assembly. The structure of the thermal superconducting assembly described in this embodiment is roughly the same as that of the thermal superconducting heat dissipation assembly described in Embodiment 1. The difference between the two lies in: In Embodiment 1, the heat dissipation fin plate structure 2 includes a first heat dissipation fin plate 22, and the first heat dissipation fin plate 22 is located on a surface of the thermal superconducting heat dissipation plate 1; while in this embodiment The heat dissipation fin plate structure 2 includes two first heat dissipation fin plates 22 , and the two first heat dissipation fin plates 22 are respectively located on two opposite surfaces of the thermal superconducting heat dissipation plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com