A method and device for combined thermal energy recovery of thermal phosphoric acid and polyphosphoric acid micro-absorption

A thermal phosphoric acid and heat energy recovery technology, which is applied in the steam generation method using heat carrier, phosphoric acid, phosphorus oxyacid, etc., can solve the problem of expensive, unconsidered recovery of high-temperature exhaust heat energy and hydration reaction heat, and weakened heat recovery. benefits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] For every ton of phosphorus-containing phosphoric acid or polyphosphoric acid produced, the air quality required for the combustion of the by-product tail gas produced by the electric furnace method is 34 tons, the air quality required for yellow phosphorus combustion is 5 tons, and the air quality for heat recovery is 15 tons. tons, the water quality for heat recovery is 5 tons.

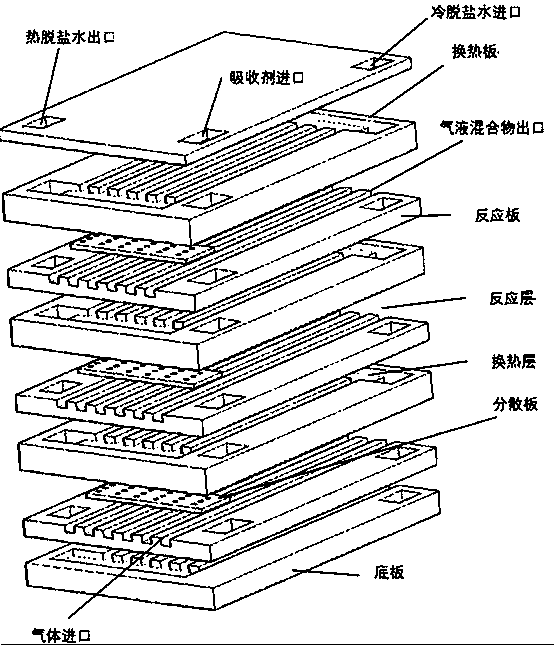

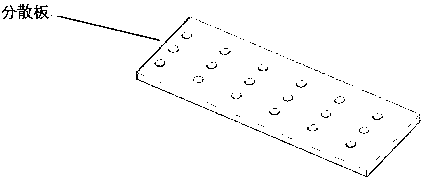

[0035] Used micro-absorption-heat exchanger 2, the hydraulic radius of the reaction plate parallel channel is 0.1mm, the hydraulic radius of the dispersion hole is 0.01mm, the angle between the axis of the dispersion hole and the parallel channel axis is 20°, and the residence time of the material is 0.1s; the heat exchange plate is a cavity with a gap of 0.1mm or a parallel channel with a hydraulic radius of 0.1mm.

Embodiment 2

[0037] For every ton of phosphoric acid or polyphosphoric acid containing phosphorus, the air quality required for the combustion of the by-product tail gas produced by the electric furnace method is 52 tons, the air quality required for yellow phosphorus combustion is 10 tons, and the air quality for heat recovery is 40 tons. tons, the water quality for heat recovery is 30 tons.

[0038] For the micro-absorption-heat exchanger 2 used, the hydraulic radius of the reaction plate parallel channel is 10mm, the hydraulic radius of the dispersion hole is 2mm, the angle between the axis of the dispersion hole and the parallel channel axis is 55°, and the residence time of the material is 5s; The heat exchange plates are cavities with a gap of 10 mm or parallel channels with a hydraulic radius of 10 mm.

Embodiment 3

[0040] For every ton of phosphorus-containing phosphoric acid or polyphosphoric acid produced, the air quality required for the combustion of the by-product tail gas produced by the electric furnace method is 70 tons, the air quality required for yellow phosphorus combustion is 15 tons, and the air quality for heat recovery is 70 tons. tons, the water quality for heat recovery is 50 tons.

[0041] In the micro-absorption-heat exchanger 2 used, the hydraulic radius of the reaction plate parallel channel is 20mm, the hydraulic radius of the dispersion hole is 4mm, the angle between the axis of the dispersion hole and the parallel channel axis is 90°, and the residence time of the material is 10s; The heat exchange plates are cavities with a gap of 20 mm or parallel channels with a hydraulic radius of 20 mm.

[0042] Through the tests of Examples 1, 2, and 3, the above-mentioned test data can all have a relatively good test structure, which meets the production requirements of ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com