A sand casting method for the front frame of 18kw film and television lamps

A technology of sand casting and lamps, which is applied in the direction of casting molding equipment, cores, casting molds, etc. It can solve the problems of cold insulation and insufficient pouring, large shrinkage of magnesium alloys, and entry of oxidized slag into castings, etc., to solve the problem of large shrinkage and solution loose casting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A sand casting method for the front frame of a 18KW film and television lamp according to the present invention, the process steps are as follows:

[0021] 1) Mixed resin sand: The resin sand is made by mixing the following components according to mass percentage, 80 mesh quartz sand: phenol urethane resin NP301: phenol urethane resin NP302=100:0.5: 1.2, mixing When making, first add quartz sand and phenol urethane resin NP301, mix and stir for 2 minutes, then add phenol urethane resin NP302 and mix for 3 minutes to obtain usable resin sand;

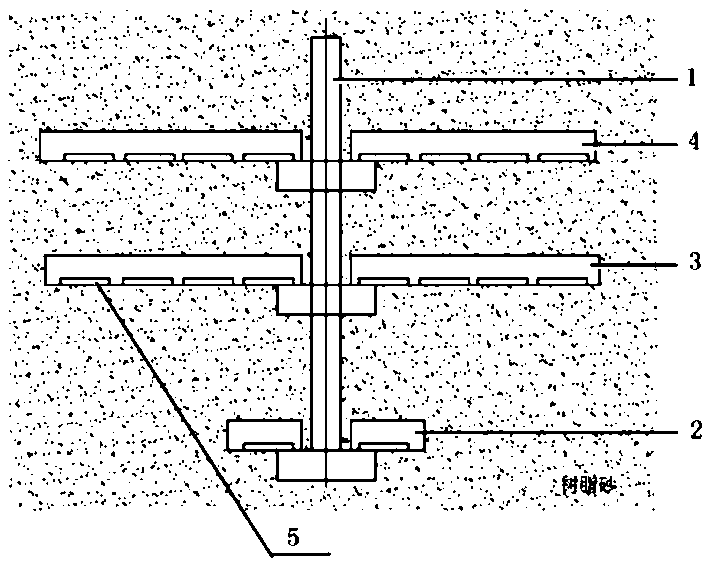

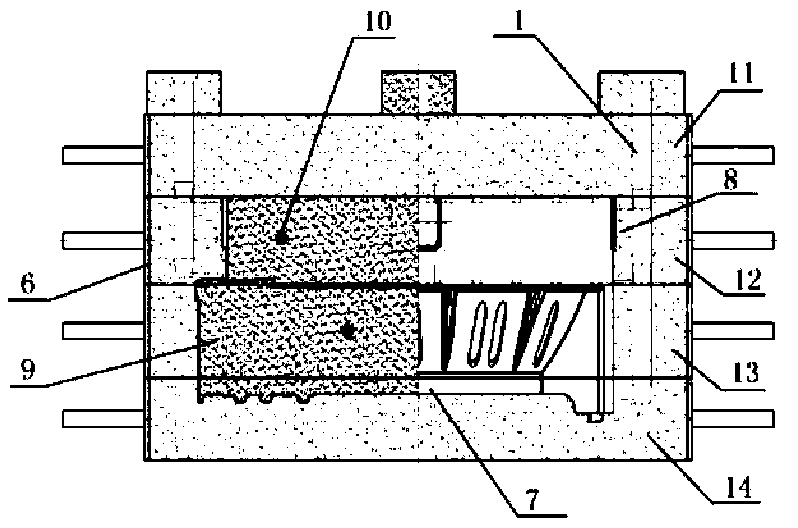

[0022] 2), molding core making: refer to figure 1 and figure 2 , adopts four-box shape and three-layer stepped runner system, the three-layer runner connects the sprue and the inner runner, and the three-layer runner is separated by sand, which can reduce the magnesium liquid entering from different sprues Mutual impact causes the pressure of the magnesium liquid to decrease, and the molded chill iron is added at the hot juncti...

Embodiment 2

[0032] According to Embodiment 1, a sand casting method for the front frame of a 18KW film and television lamp according to the present invention, the process steps are as follows:

[0033] 1) Mixed resin sand: The resin sand is made by mixing the following components according to mass percentage, 140 mesh quartz sand: phenol urethane resin NP301: phenol urethane resin NP302=100: 1.2:0.5, mixing First add quartz sand and phenolurethane resin NP301, mix and stir for 3 minutes, then add phenolurethane resin NP302 and mix for 2 minutes to obtain usable resin sand;

[0034] 2) Molding core making: four-box molding and three-layer stepped runner system are adopted. The runners are connected to the straight runner and the inner runner. Iron; during the core making process, a core bone is added to a core with a circular wall thickness;

[0035] 3) Sand spraying: After the molding is completed, spray a layer of paint on the inner wall of the cavity and the surface of the core. The pa...

Embodiment 3

[0040] According to Embodiment 1, a sand casting method for the front frame of a 18KW film and television lamp according to the present invention, the process steps are as follows:

[0041] 1) Mixed resin sand: The resin sand is made by mixing the following components according to mass percentage, 100 mesh quartz sand: phenol urethane resin NP301: phenol urethane resin NP302=100: 1.0: 1.0, mixing First add quartz sand and phenol urethane resin NP301, mix and stir for 2.5 minutes, then add phenol urethane resin NP302 and mix and stir for 2.5 minutes to obtain usable resin sand;

[0042] 2) Molding core making: four-box molding and three-layer stepped runner system are adopted. The runners are connected to the straight runner and the inner runner. Iron; during the core making process, a core bone is added to a core with a circular wall thickness;

[0043] 3) Sand spraying: After the molding is completed, a layer of paint is sprayed on the inner wall of the cavity and the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com