Preparation method and application of g-C3N4-Cu2O composite catalyst

A composite catalyst, g-c3n4-cu2o technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of photocatalytic efficiency to be improved, to ensure photocatalytic performance, strong Effect of Visible Light Absorptivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

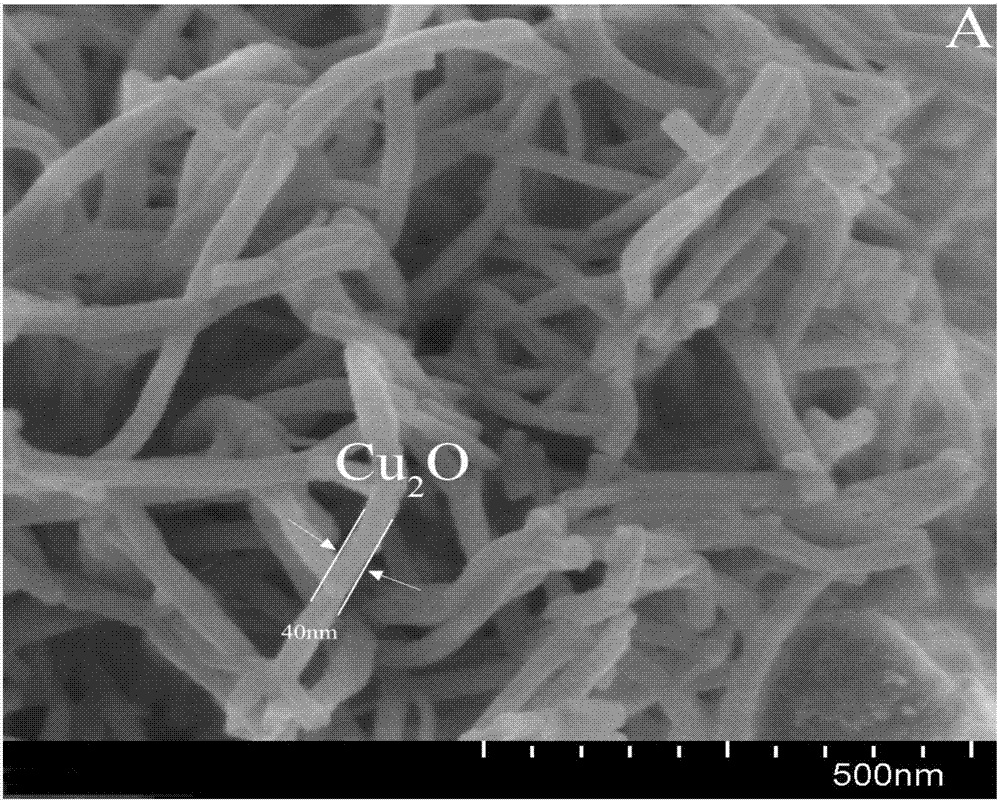

Image

Examples

preparation example Construction

[0035] Embodiments of the present invention g-C 3 N 4 -Cu 2 The preparation method of O composite catalyst comprises the steps:

[0036] providing a first solution comprising Cu in a dissolved state 2+ ;

[0037] Add protonated g-C to the first solution 3 N 4 , stirred, sonicated to obtain a suspension;

[0038] Add xylitol to the suspension under stirring, adjust the pH value to 10-12, and stir to obtain a mixed solution;

[0039] Heating the mixed solution to 150-200°C in a high-pressure reaction vessel, and reacting at a constant temperature for 25-35 hours to obtain a reactant;

[0040] The solid-liquid separation of the reactant after cooling to obtain a solid product, washing, and vacuum drying;

[0041] The solid product is heated to 150-250°C under the protection of the atmosphere and kept at a constant temperature for 1h-3h to obtain g-C 3 N 4 -Cu 2 O composite catalyst.

[0042] Graphite carbon nitride (g-C 3 N 4 ) is a typical n-type semiconductor mate...

Embodiment 1

[0047] Raw Materials and Reagents

[0048] Dicyandiamide (C 2 h 4 N 4 ), copper sulfate pentahydrate (CuSO 4 ·5H 2 O), sodium hydroxide (NaOH), and hydrochloric acid (HCl) were of analytical grade (AR), purchased from Sinopharm Chemical Reagent Co., Ltd.; xylitol (C 5 h 12 0 5 ), methyl orange (C 14 h 14 N 3 NaO 3 S) were analytically pure (AR), purchased from Shanghai Aladdin Biochemical Technology Co., Ltd.

[0049] Protonated g-C 3 N 4 preparation of

[0050] After heating dicyandiamide to 550°C at a heating rate of 2K / min, calcining for 4 hours, cooling, and grinding the obtained light yellow powder; adding concentrated sulfuric acid to the ground powder for mixing, stirring, and ultrasonication to obtain a mixture; The mixture is mixed with water and stirred to obtain a milky white suspension, which is centrifuged, washed and dried to obtain acidified g-C 3 N 4 ; The acidified g-C 3 N 4 Reflux at 65°C for 6h, filter with suction, wash and dry to obtain g...

Embodiment 2

[0054] Protonated g-C 3 N 4 preparation of

[0055] After heating dicyandiamide to 500°C at a heating rate of 1K / min, calcining for 5 hours, cooling, and grinding the obtained light yellow powder; adding concentrated sulfuric acid to the ground powder for mixing, stirring, and ultrasonication to obtain a mixture; The mixture is mixed with water and stirred to obtain a milky white suspension, which is centrifuged, washed and dried to obtain acidified g-C 3 N 4 ; The acidified g-C 3 N 4 Reflux at 50°C for 8h, filter with suction, wash and dry to obtain g-C 3 N 4 .

[0056] g-C 3 N 4 -Cu 2 Preparation of O composite photocatalyst

[0057] The g-C 3 N 4 grow to Cu 2 O surface, the specific steps are as follows: first, 1.25g CuSO 4 ·5H 2 O was added to 40mL deionized water, when the solution turned dark blue, continue to add g-C to the above solution 3 N 4 The powder was magnetically stirred for 2 hours and then ultrasonically continued for 2 hours to obtain a hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com