Temperature adjustable carbon crystal heating plate

A heating plate, carbon crystal technology, applied in electric heating devices, heating element materials, ohmic resistance heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Preferably, the preparation method of the modified carbon nanotubes comprises: soaking 10-20nm carbon nanotubes in concentrated sulfuric acid at 40-50°C for 15-25min, and then putting the soaked carbon nanotubes into a ball mill for grinding Truncated to obtain the modified carbon nanotubes.

[0021] By introducing modified carbon nanotubes and utilizing the combination of modified carbon nanotubes and nano bamboo charcoal powder, the conductivity of the heating paste is improved.

[0022] Preferably, the ceramic emitter is Al 2 o 3 , MnO 2 , SiO 2 、TiO 2 , ZrO 2 one or more of.

[0023] Preferably, the ceramic emitter is Al 2 o 3 , SiO 2 and ZrO 2 a mixture of, and, the AL 2 o 3 , SiO 2 and ZrO 2 The mass ratio is 3:(2-3):(2-3).

[0024] The far-infrared emissivity of the heat-generating slurry used in the present invention reaches more than 80%. 2 o 3 , SiO 2 and ZrO 2 The far-infrared emissivity of the combination whose mass ratio is 3:(2-3):(2-3) ...

Embodiment 1

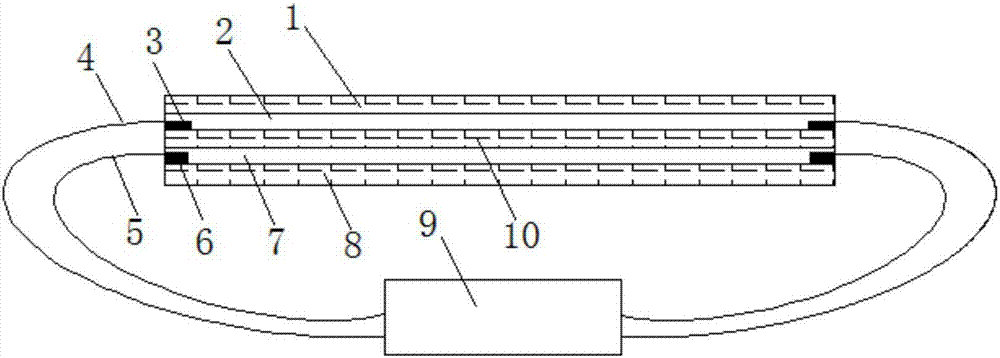

[0035] figure 1 A schematic diagram of a temperature-adjustable carbon crystal heating plate according to an embodiment of the present invention is shown.

[0036] Such as figure 1 As shown, the present invention provides a temperature-adjustable carbon crystal heating plate, which includes: a first resin layer 8, a first carbon crystal heating layer 7 is arranged on the first resin layer 8, and the first resin The two ends of the layer 8 are respectively welded with a first copper strip 6, the first copper strip 6 is covered by the first carbon crystal heating layer 7; a second resin layer 10, the second resin layer 10 is arranged on the first carbon crystal heating layer 7 On a carbon crystal heating layer 7, a second carbon crystal heating layer 2 is arranged on the second resin layer 10, and the two ends of the second resin layer 10 are respectively welded with second copper strips 3, and the second copper strips 3 is covered by the second carbon crystal heating layer 2;...

Embodiment 2

[0040] Such as figure 1 As shown, the specific structure and material of the temperature-adjustable carbon crystal heating plate of this implementation are all the same as in Example 1;

[0041] The specific ingredients of the heat generating slurry used in the first carbon crystal heat generating layer 7 and the second carbon crystal heat generating layer 2 include: in parts by mass, 18 parts of modified carbon nanotubes, 8 parts of nano bamboo charcoal powder, ceramic 13 parts of propellant, 23 parts of epoxy resin paint, 28 parts of epoxy resin paint solvent, 3 parts of curing agent, 8 parts of silicon micropowder, 1.5 parts of polycarboxylate ammonium salt ceramic dispersant, 1.5 parts of silane coupling agent; The ceramic emitter is Al 2 o 3 , SiO 2 and ZrO 2 a mixture of the Al 2 o 3 , SiO 2 and ZrO 2 The mass ratio is 3:2:2, and the epoxy resin paint is hydrogenated bisphenol A type epoxy resin paint, and the epoxy resin paint solvent is turpentine, and the curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com