Temperature-adjustable carbon crystal heating plate

A technology of carbon crystal heating area and heating plate, applied in the direction of electric heating device, heating element material, ohmic resistance heating, etc., can solve the problems of non-adjustable temperature and inability to realize the conversion of heating energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] Preferably, the preparation method of the ceramic emitter comprises: MgO, ZrO 3 、Ni 2 o 3 , mica powder and rare earth oxides are ground and mixed in a ball mill, and then calcined, and finally the calcined product is ground again in the ball mill to obtain the ceramic propellant; each component of the ceramic propellant Content, in parts by mass, MgO 5-10 parts, ZrO 3 3-5 copies, Ni 2 o 3 3-5 parts, 2-3 parts of mica powder and 1-2 parts of rare earth oxide.

[0017] In the present invention, the far-infrared emissivity of the heat-generating slurry used can reach more than 84% by adding the ceramic emissive composition;

[0018] Preferably, the temperature of the calcination is 1000-1500° C., and the time is 2-3 hours.

[0019] Preferably, the rare earth oxide is praseodymium oxide and / or lanthanum oxide.

[0020] As a preferred solution, the rare earth oxide is a mixture of lanthanum oxide and praseodymium oxide, and the mass ratio of the lanthanum oxide to t...

Embodiment 1

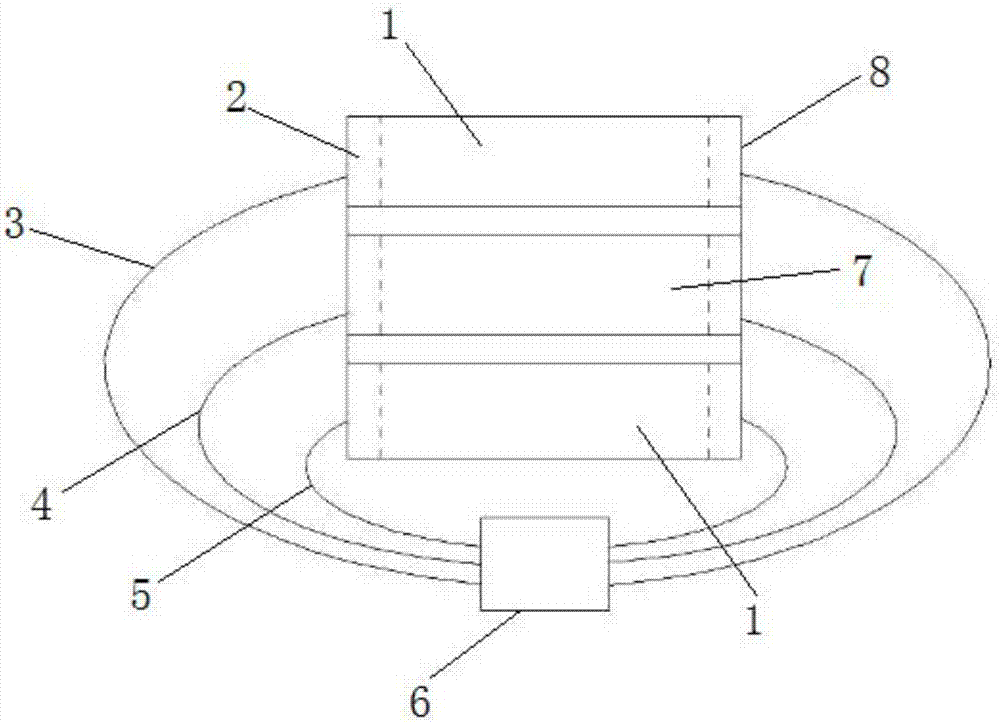

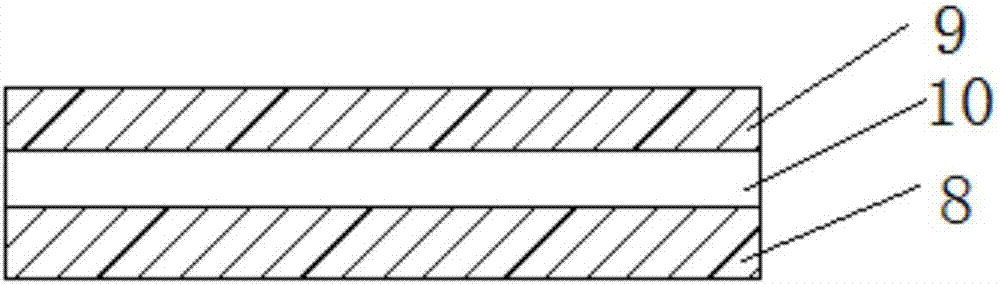

[0036] Such as Figure 1-Figure 2 As shown, the present invention provides a temperature-adjustable carbon crystal heating plate, which includes: a first resin layer 8, a second resin layer 9, and The carbon crystal heating area 10 between them; the carbon crystal heating area 10 includes, the first carbon crystal heating area 7 located in the middle of the first resin layer 8 and the second carbon crystal heating area 1 located at both ends, the first carbon crystal heating area 1 A carbon crystal heating zone 7 and the lower parts of both sides of the second carbon crystal heating zone 1 are respectively provided with copper strips 2 welded on the first resin layer 8, and the first carbon crystal heating zone 7 and the two ends There is a gap between the second carbon crystal heating area 1; wherein, the first power supply pair 4 is arranged on the copper bars 2 on both sides of the first carbon crystal heating area 7, and the second carbon crystal heating area The copper s...

Embodiment 2

[0040] Such as Figure 1-Figure 2 As shown, the specific structure and material of the temperature-adjustable carbon crystal heating plate of this implementation are all the same as in Example 1;

[0041] The specific ingredients of the heat-generating slurry used in the first carbon crystal heating zone 7 and the second carbon crystal heating zone 1 include: in parts by mass, 17 parts of graphite, 8 parts of nano-bamboo charcoal powder, and 13 parts of ceramic propellant , 23 parts of epoxy resin paints, 28 parts of epoxy resin paint solvents, 3 parts of curing agents, 8 parts of silicon micropowder, 3 parts of dispersants and silane coupling agents, the mass ratio of the dispersants and the silane coupling agents It is 1:0.8; described epoxy resin paint is hydrogenated bisphenol A type epoxy resin paint, and described epoxy resin paint solvent is turpentine, and described curing agent is m-xylylenediamine; Wherein, described ceramic launcher The preparation method includes:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com