Water-shedding fabric and umbrella made from the same

A fabric and fabric technology is applied in the field of non-wet fabrics and umbrellas made of the fabrics, which can solve the problems of poor rainwater hydrophobicity, inconvenience to carry, and indoor environment troubles, and is conducive to sustainable development and improvement. The effect of convenience of life and excellent hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

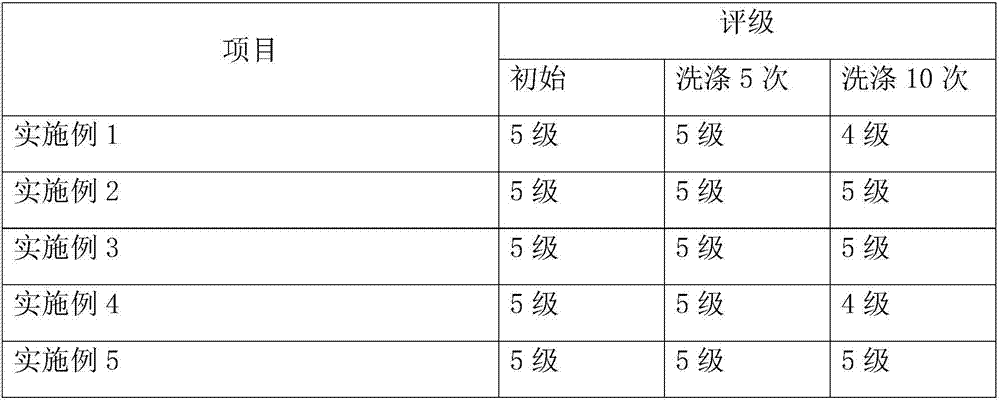

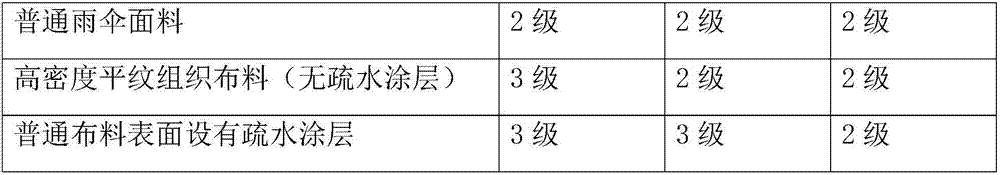

Embodiment 1

[0038] A non-sticky fabric, using 30 denier ultra-fine polyester fiber woven into a high-density plain weave cloth with a density of 200T, and a hydrophobic coating is provided on the surface of the cloth, and the hydrophobic coating includes no significant electricity generation Dipole moment organics and hydrocarbyl groups, ester groups, halogens, nitro groups and other additives that reduce the surface tension of the fabric with hydrophobic groups.

[0039] In this embodiment, the hydrophobic coating liquid includes the following components: three-prevention additives 50g / L; melamine resin 25g / L; silicon-based smoothing agent 5g / L; crosslinking agent 3g / L; high-concentration agent 0.5g / L; the rest is water to form a 1L solution.

[0040] In this embodiment, the fabric is prepared by the following method:

[0041] S1, weaving high-density plain weave fabric;

[0042] S2, prepare hydrophobic coating liquid;

[0043] S3. Fully crosslink the hydrophobic coating material liquid on the s...

Embodiment 2

[0045] A non-sticky fabric, using ultrafine polyester fiber with a fineness of 50 denier to woven a high-density plain weave cloth with a density of 400T, and providing a hydrophobic coating on the surface of the cloth, the hydrophobic coating including no significant electricity generation Dipole moment organics and hydrocarbyl groups, ester groups, halogens, nitro groups and other additives that reduce the surface tension of the fabric with hydrophobic groups.

[0046] In this embodiment, the hydrophobic coating liquid includes the following components: three-prevention additives 70g / L; melamine resin 35g / L; silicon-based smoothing agent 15g / L; crosslinking agent 7g / L; high concentration agent 1.5g / L; the rest is water to form a 1L solution.

[0047] In this embodiment, the fabric is prepared by the following method:

[0048] S1, weaving high-density plain weave fabric;

[0049] S2, prepare hydrophobic coating liquid;

[0050] S3. Fully cross-link the hydrophobic coating liquid on t...

Embodiment 3

[0052] A non-sticky fabric, using ultra-fine polyester fiber with a fineness of 40 denier to woven a high-density plain weave fabric with a density of 400T, and a hydrophobic coating on the surface of the fabric, the hydrophobic coating including no significant Electric dipole moment organics and hydrocarbyl, ester, halogen, nitro and other additives that reduce the surface tension of the fabric and hydrophobic groups.

[0053] In this embodiment, the hydrophobic coating liquid includes the following components: three-prevention additives 60g / L; melamine resin 30g / L; silicon smoothing agent 10g / L; crosslinking agent 5g / L; high-concentration agent 1g / L; the rest is water to form a 1L solution.

[0054] In this embodiment, the fabric is prepared by the following method:

[0055] S1, weaving high-density plain weave fabric;

[0056] S2, prepare hydrophobic coating liquid;

[0057] S3. Fully cross-link the hydrophobic coating material liquid on the surface of the high-density plain weave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com