Continuous bending and forming device of ring

A bending forming and ring technology, applied in forming tools, heat treatment equipment, metal processing equipment, etc., can solve the problems of high material waste rate, low processing efficiency, low processing accuracy, etc., and achieve high processing efficiency and high processing accuracy. , good size consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

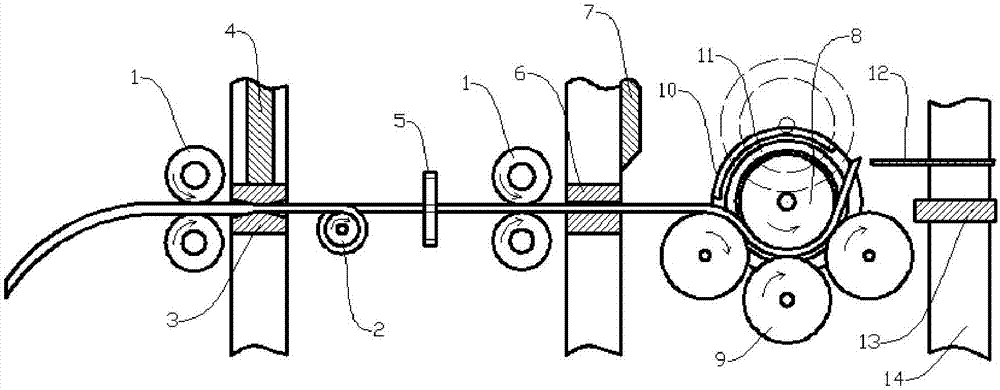

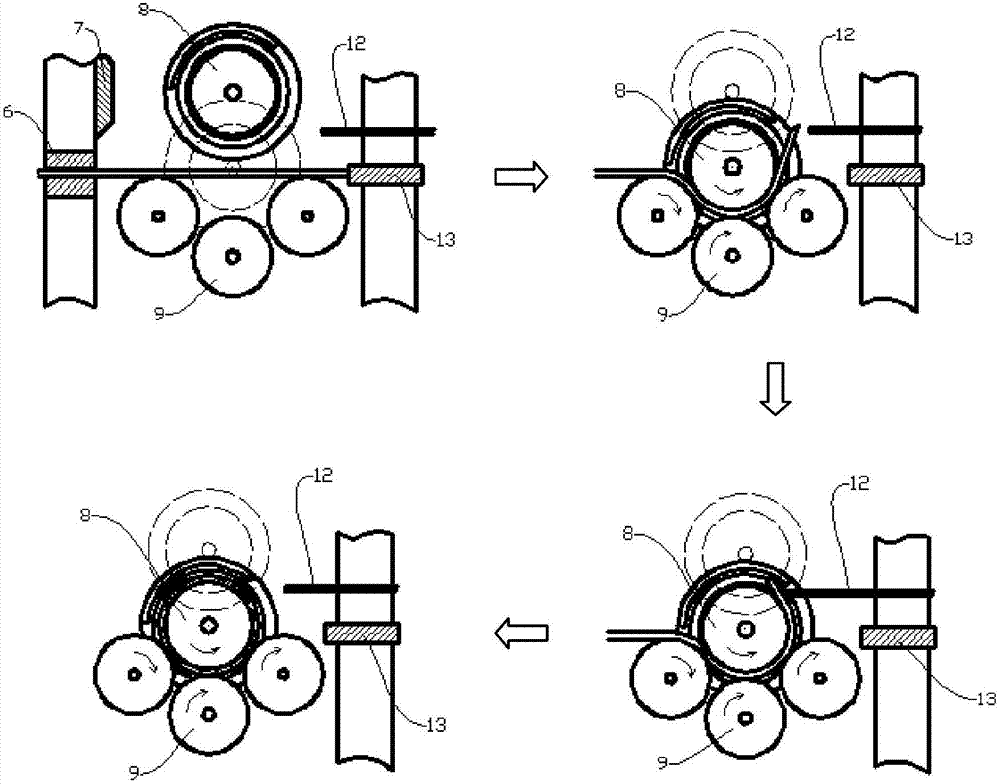

[0025] The present invention will be described in detail below with reference to the accompanying drawings.

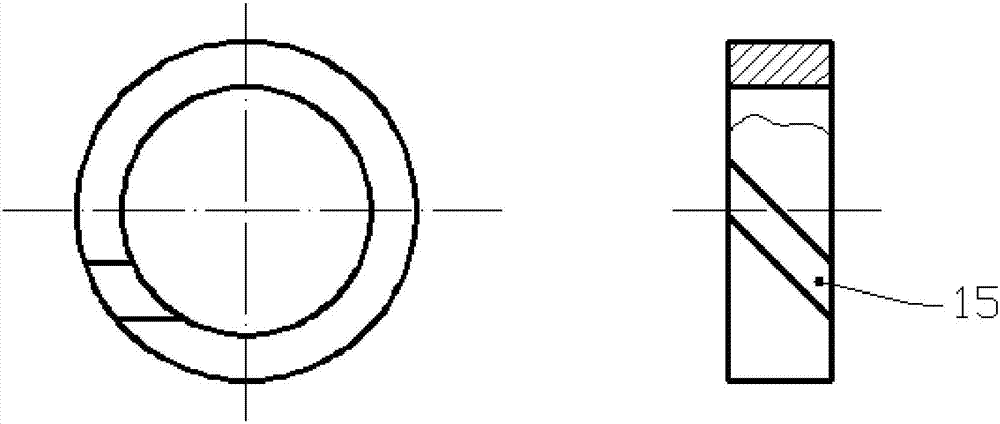

[0026] The structure created by the present invention is as figure 2 As shown, it includes a feeding mechanism and a shaping mechanism, an annealing mechanism, a cutting mechanism, and a rolling forming mechanism arranged in sequence along the feeding direction; the feeding mechanism is used to transport strip-shaped raw materials, and the shaping mechanism is used to continuously pass The section of the strip-shaped raw material is continuously processed into the shape and size required by the finished product. The annealing mechanism is used to continuously anneal the strip-shaped raw material to a suitable state for roll forming processing. The strip-shaped raw material is cut, and the rolling forming mechanism is used to roll the strip-shaped raw material into a ring-shaped finished product; the rolling forming mechanism is provided with a lifting mechanism; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com