Method for preparing high-performance Ti6Al4V alloy plate

A high-performance alloy plate technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of material component performance degradation, cracks, etc., and achieve the effect of improving mechanical properties and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

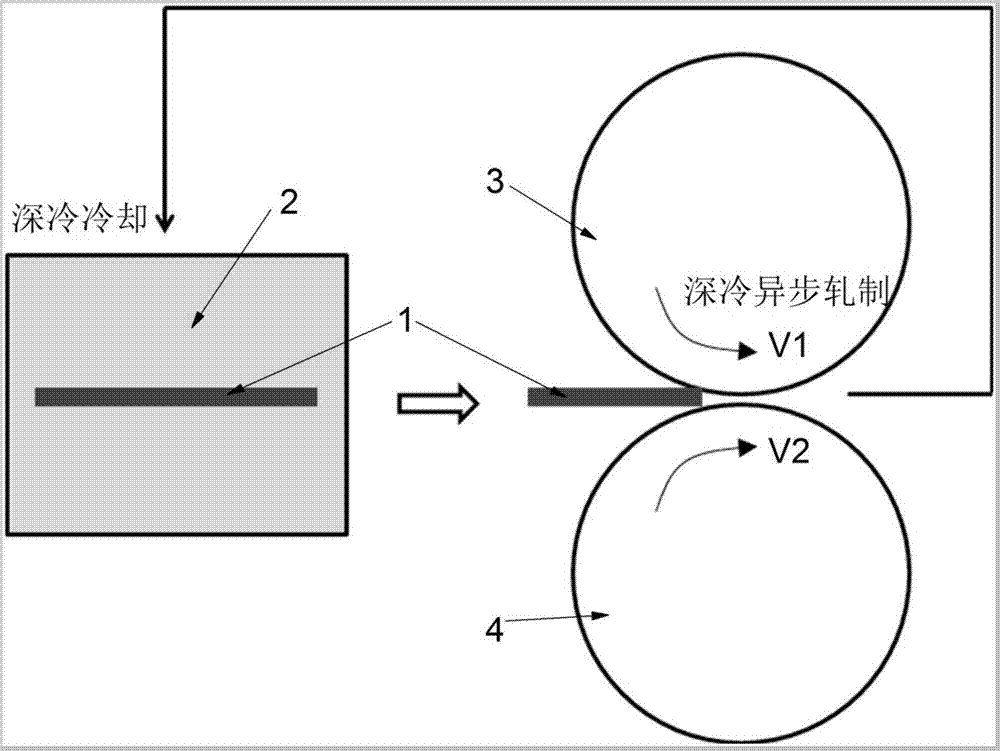

[0014] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0015] Such as figure 1 Shown, a kind of method for preparing high performance Ti6Al4V alloy plate, the steps are as follows:

[0016] Step 1: use Ti6Al4V hot-rolled plate 1 as raw material, and the thickness of the plate is 1.5mm-3.5mm.

[0017] Step 2: put the material into the cryogenic box 2 for cooling, lower the temperature of the rolled piece to -190°C, and keep it warm for 10 minutes.

[0018] The third step: take out the material and carry out cold rolling. The rolling speed of the upper roll 3 and the lower roll 4 are V1 and V2 respectively, and the speed ratio V1 of the upper and lower rolls is strictly controlled: V2=1.1~1.2. According to the low-temperature performance characteristics of Ti6Al4V, the rolling reduction rate of each pass is strictly controlled at 5%-10%.

[0019] Repeat the second and third steps until the total r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com