Oil-immersion conveyor

A conveyor and conveying mechanism technology, applied in the direction of liquid injection device, pretreatment surface, injection device, etc., can solve the problems of product bruising, low efficiency, product quality decline, etc., to avoid product damage and waste, and improve product quality , fully oiled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

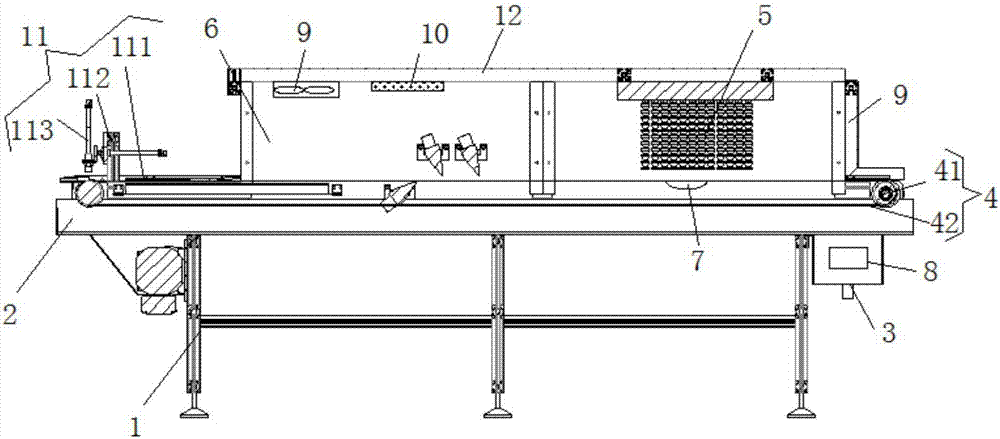

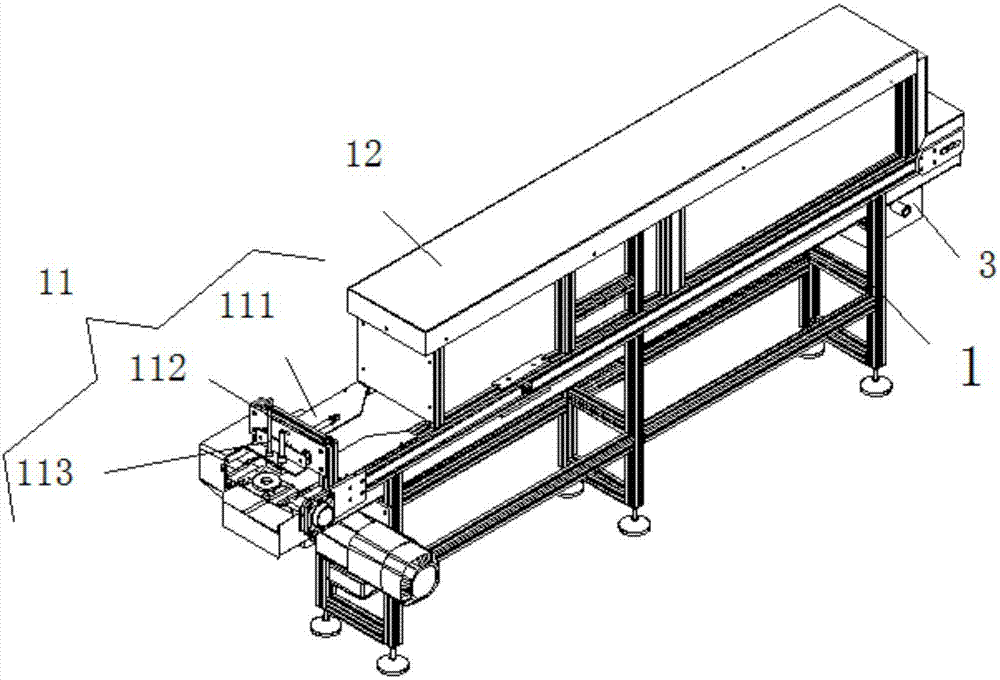

[0020] An oil-immersed conveyor, comprising a frame 1, the upper end of the frame 1 is fixedly provided with an oil receiving tank 2, an oil tank 3 is installed on the right side of the oil receiving tank 2, and an oil well pump 8 is installed in the oil tank 3, the An oil injection delivery mechanism 4 is installed above the oil tank 3, and the oil injection delivery mechanism 4 includes a motor 41 and a conveyor belt 42, the motor 41 is connected to the conveyor belt 42 through a rotating shaft, and the upper rear portion of the frame 4 is provided with The oil baffle 6, the right end of the oil baffle 6 is located on the top of the conveyor belt 42 and is provided with a spray system 5, and the bottom of the spray system 5 is located in the middle of the conveyor belt 42 and an ultrasonic vibrator 7 is installed. The oil baffle 6 A circulating fan 9 and a heating system 10 are installed on the top of the conveyor belt 42 at the left end of the conveyor belt 42, and a pusher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com