Flexible cell based on metallic oxide/graphene composite macroscopic fibers and preparation method

A graphene composite and macro-fiber technology, which is applied in the manufacture of secondary batteries, battery electrodes, circuits, etc., can solve the problems of metal fibers without electrochemical properties, small active materials, easy to fall off, etc., to achieve excellent electrochemical properties, Good mechanical properties, avoid the effect of easy falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 4mg / mL Ti 0.87 o 2 0.52- The aqueous solution was mixed with a 3.9 mg / mL graphene oxide aqueous solution and added to the wet spinning equipment, and injected into an aqueous solution containing 0.6% chitosan (Ti 0.87 o 2 0.52- The mass ratio of graphene oxide to graphene oxide is 4), spun at 5mL / min to obtain as-spun fibers, and the as-spun fibers were stretched and oriented at a drawing speed of 2 times, washed with ultrapure water three times, and dried at 28°C for 24 hours to obtain Metal oxide and graphene oxide composite fibers. Put the composite fiber in 57% hydroiodic acid, soak and reduce it for 4.5 hours at a temperature of 90 degrees, take it out and wash it repeatedly with ultrapure water and ethanol, and then dry it naturally in the air to obtain a composite macroscopic fiber of metal oxide and graphene. .

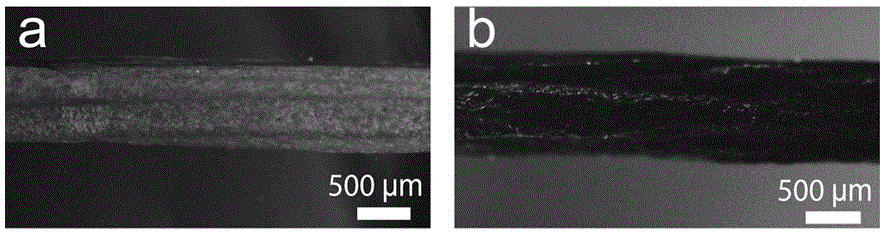

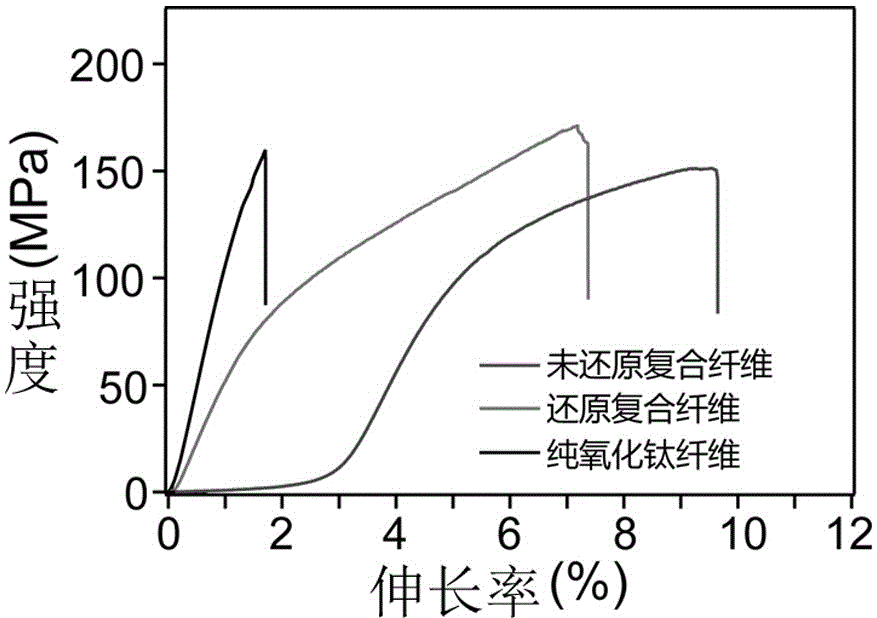

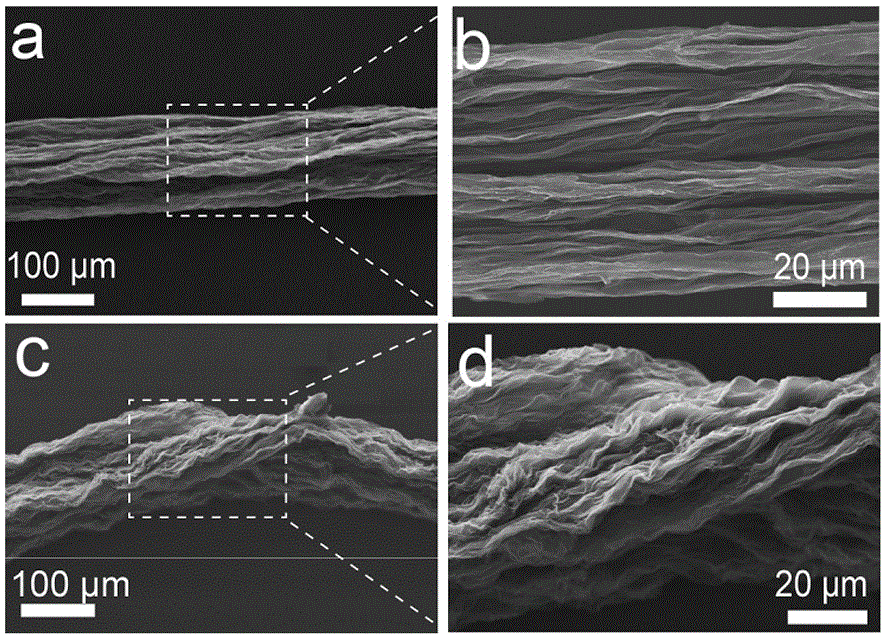

[0034] attached figure 1 a is the optical photo of metal oxide and graphene oxide composite macroscopic fiber, attached figure 1 b is the optic...

Embodiment 2

[0041] 2mg / mL Ti 0.87 o 2 0.52- The aqueous solution was mixed with a 2 mg / mL graphene oxide aqueous solution and added to the wet spinning equipment, and injected into an aqueous solution containing 1.5% chitosan (Ti 0.87 o 2 0.52- The mass ratio to graphene oxide is 4), 0.1mL / min spinning to obtain as-spun fibers, and the as-spun fibers were stretched and oriented at a drawing speed of 2 times, washed with ultrapure water three times, and then dried at 28°C for 24 hours. Obtain metal oxide and graphene oxide composite fiber. Soak the composite fiber in 57% hydroiodic acid for 4.5 hours at a temperature of 90 degrees, take it out, wash it repeatedly with ultrapure water and ethanol, and dry it naturally in the air to obtain a composite fiber of metal oxide and graphene.

[0042] The composite fiber and lithium wire are respectively used as the positive and negative electrodes to connect the copper wire current collector and put them into the heat shrinkable tube in paral...

Embodiment 3

[0045] 4mg / mL Ti 0.87 o 2 0.52- The aqueous solution was mixed with a 3.9 mg / mL graphene oxide aqueous solution and added to the wet spinning equipment, and injected into an aqueous solution containing 0.6% chitosan (Ti 0.87 o 2 0.52- The mass ratio to graphene oxide is 4), 2mL / min spinning to obtain primary fibers. The as-spun fibers were stretched and oriented at 2 times the stretching speed, washed three times with ultrapure water, and then dried at 28°C for 24 hours to obtain metal oxide and graphene oxide composite fibers. Soak the composite fiber in 57% hydroiodic acid for 4.5 hours at a temperature of 70 degrees, take it out, wash it repeatedly with ultrapure water and ethanol, and dry it naturally in the air to obtain a composite fiber of metal oxide and graphene.

[0046] The composite fiber and the lithium wire are respectively used as the positive electrode and the negative electrode to connect the copper wire current collector and put them in parallel into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com