In-vitro gradient degrading method for multi-crosslinked chitosan or derivative gel of multi-crosslinked chitosan

A chitosan gel, cross-linked chitosan technology, applied in biochemical equipment and methods, microbial determination/inspection, chemical method analysis, etc., can solve problems such as few reports on the degradation of cross-linked chitosan , to achieve the effect of simple operation and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

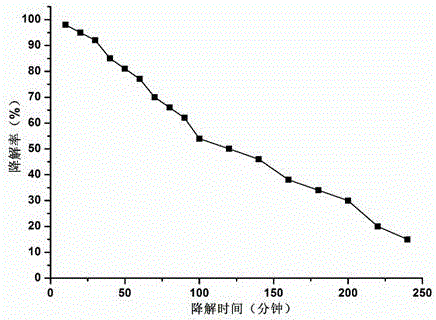

[0057] Example 1: Free Radical Degradation of Triple Crosslinked Chitosan Gels

[0058] Prepare an ascorbic acid solution with a concentration of 0.01mol / L, and adjust it to pH=3 with 3 mol / L hydrochloric acid; take cross-linked chitosan (deacetylation degree 90%, molecular weight 20KDa, three times cross-linked, mass concentration 30mg / mL, cross-linked chitosan Place 2 mL of the gel in a 50 mL centrifuge tube, add 2 mL of the above ascorbic acid solution, and cool to 0°C, where the concentration of ascorbic acid is 0.01 mol / L; keep the environment at 0°C, add hydrogen peroxide solution 2 mL, the concentration of hydrogen peroxide is 0.01 mol / L; the system is placed in a constant temperature water bath shaker, the shaking temperature is set at 37°C, samples are taken every 10 minutes for the first 100 minutes, and samples are taken every 20 minutes thereafter, taking out 100 μL of degradation solution each time At the same time, the above-mentioned ascorbic acid solution was 1...

Embodiment 2

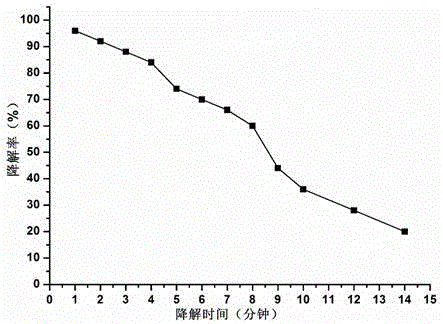

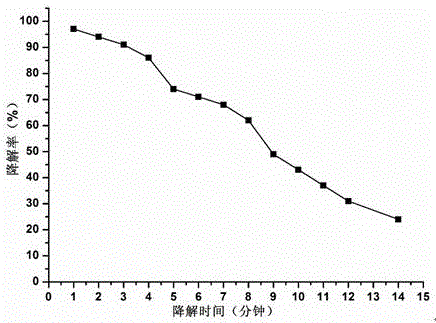

[0059] Example 2: Lysozyme degradation of triple cross-linked chitosan gels

[0060] Take 2 mL of cross-linked chitosan (deacetylation degree 90%, molecular weight 20KDa, three times of cross-linking, mass concentration 30mg / mL, cross-linking degree 2%) in a 50 mL centrifuge tube, add 2 mL concentration of 0.01 mol / L phosphate buffer (pH 7.2), add 800 u lysozyme, and cool to 0°C; place the system in a constant temperature water bath shaker, set the shaking temperature to 37°C, and take samples every 1 h for the first 12 hours After that, samples were taken every 2 hours, and 100 μL of the degradation solution was taken out each time, and 100 μL of the above-mentioned phosphate buffer solution was added at the same time. The total degradation time was 14 hours; the degradation solution was sealed in a dialysis bag with a molecular weight cut-off of 14 KDa, Quantitative dialysis was carried out with 5 mL of pure water for 2 h; 4.0 mL of the dialysate was taken, added with 1 mL o...

Embodiment 3

[0061] Example 3: Free radical degradation of six-fold cross-linked carboxymethyl chitosan gel

[0062] Prepare an ascorbic acid solution with a concentration of 0.01mol / L, and adjust it to pH=3 with 3 mol / L hydrochloric acid; take cross-linked carboxymethyl chitosan (deacetylation degree 90%, molecular weight 50KDa, substitution degree 1.2, mass concentration 30mg / mL, equal volumes of five gels with cross-linking degrees of 2%, 4%, 8%, 12%, and 16% and non-cross-linked carboxymethyl chitosan) gel 2 mL were placed in a 50 mL centrifuge tube, Add 2 mL of the above ascorbic acid solution, and cool to 0°C, where the concentration of ascorbic acid is 0.01 mol / L; keep the environment at 0°C, add 2 mL of hydrogen peroxide solution, the concentration of hydrogen peroxide is 0.01 mol / L; place the system in a constant temperature water bath In the oscillator, the shaking temperature was set at 37°C, samples were taken every 10 minutes for the first 100 minutes, and samples were taken ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com