Method for culturing chlorella by using crude glycerine optimized sludge dewatering liquid

A technology for sludge dehydration and crude glycerin, which is applied in the field of environmental engineering and microalgae biology, can solve the problems of difficult treatment and high cost of crude glycerin purification, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Sludge dehydration liquid treatment

[0031] The settled and filtered sludge dehydration liquid was divided into two parts: one part was used as the original water sample (without any treatment), and the other part was sterilized at 121°C for 30 minutes as the sterilized water sample for the experiment . The water quality indicators before and after sterilization are shown in Table 1.

[0032] Table 1 Water quality characteristics before and after sterilization

[0033]

Embodiment 2

[0034] Example 2: Chlorella growth under different concentrations of crude glycerol in non-sterilized sludge dehydration liquid

[0035] Centrifuge the chlorella liquid cultivated to the logarithmic phase at 4000r / min for 5 minutes, wash with deionized water three times and then centrifuge, and dehydrate the unsterilized sludge with crude glycerin concentration of 0, 1, 2, 4, 6g / L respectively Resuspend the algal bodies (numbers 0, 1, 2, 4, 6) in 600ml of liquid solution, adjust the algae density (OD) to about 0.3, and place the Erlenmeyer flask in a constant temperature light incubator. The culture conditions were 25°C, 5000 lux light, 12h:12h light-to-dark ratio, and the pH of each sewage water sample was not adjusted. Shake the Erlenmeyer flask 5 times a day and take samples regularly.

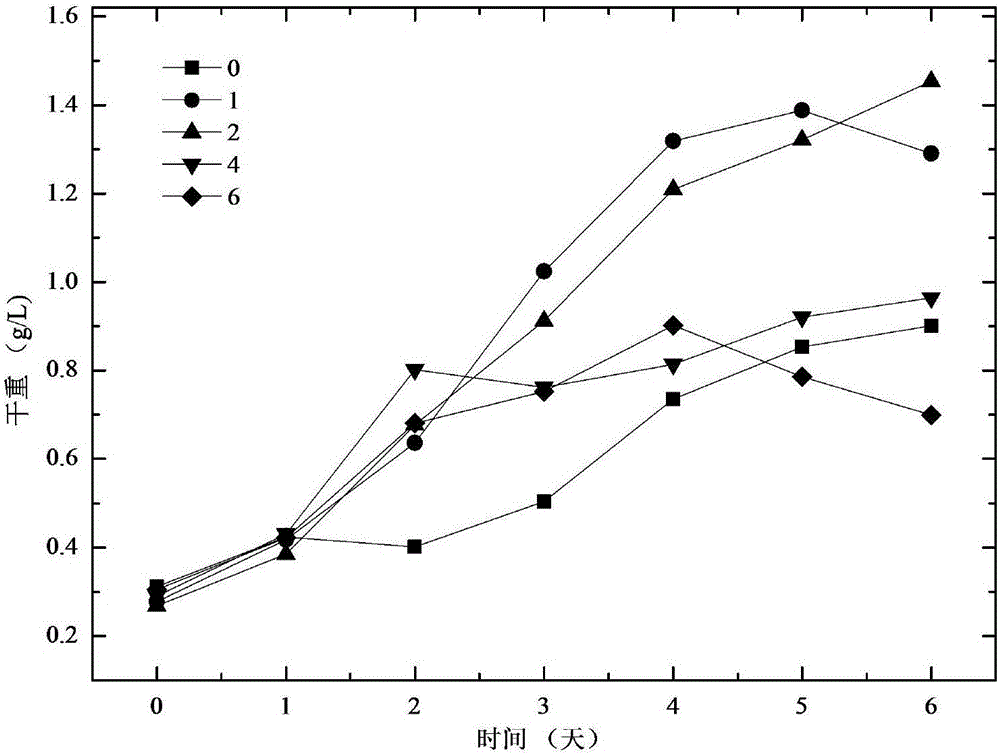

[0036] Determination of algae density (OD680nm) in the water sample, the experimental results are as follows figure 1 As shown, the biomass of Chlorella increased with the culture time un...

Embodiment 3

[0037] Example 3: Nitrogen and phosphorus consumption under different crude glycerol concentrations in unsterilized sludge dehydration liquid

[0038] The water sample sample of timing sampling among the embodiment 2 measures the change of nutrient salt (N, P) content in the water sample, and experimental result is as follows figure 2 , image 3 , Figure 4 . Such as figure 2 As shown, the ammonia nitrogen content decreased with the culture time. The removal rates of ammonia nitrogen in the non-sterilized experimental group were 64%, 98%, 99%, 95% and 91%, respectively. The ammonia nitrogen content of the crude glycerin low concentration experimental group decreased rapidly in the first two days, and was basically fully utilized on the third day, with a good removal effect.

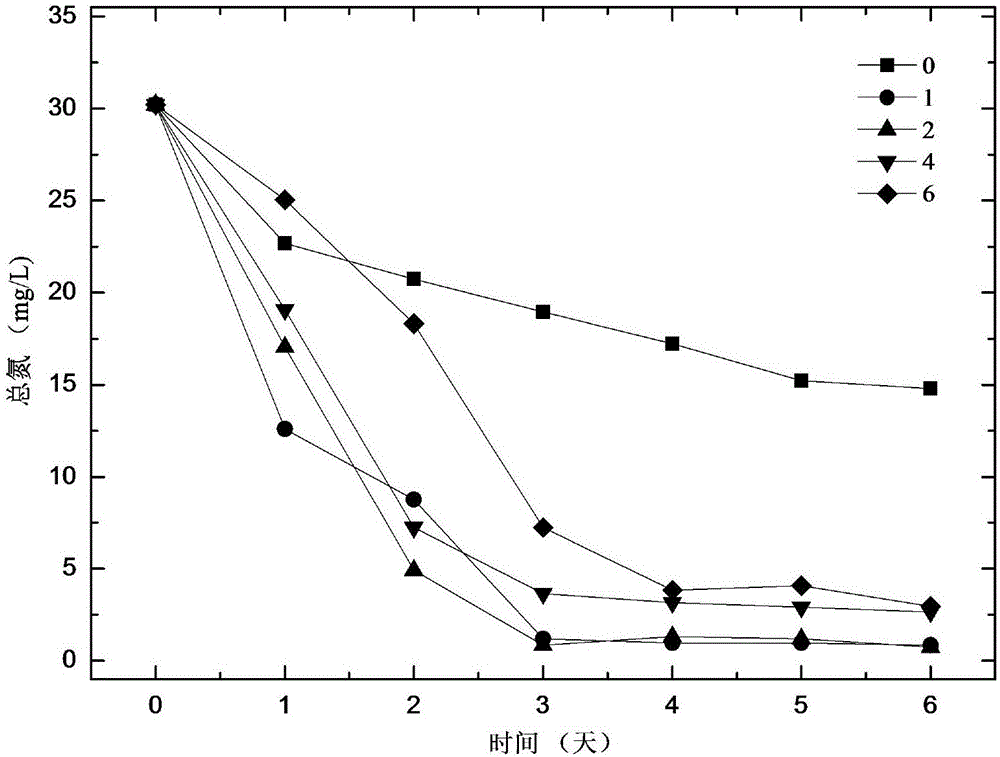

[0039] Such as image 3 As shown, the total nitrogen content decreased continuously with the culture time. The final total nitrogen content of the experimental group without crude glycerin was hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com