Ink formula, photoelectric device and preparation method for functional layer of photoelectric device

A technology of optoelectronic devices and functional layers, which is applied in the fields of electrical solid devices, chemical instruments and methods, semiconductor/solid device manufacturing, etc., and can solve problems such as uneven film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In another typical embodiment of the present application, a method for preparing a functional layer of a photoelectric device is provided, the preparation method comprising: setting A component as the first preliminary layer; setting B component in the first preliminary layer Form the second preparatory layer on the preform to obtain a preform; dry the preform to obtain the functional layer of the photoelectric device; wherein, the A component and the B group are respectively the A component and the B component in any of the above-mentioned ink formulations . The optoelectronic device can be an electroluminescent device or a solar cell or a photovoltaic cell. The aforementioned drying treatment may be any drying treatment, such as vacuum drying, infrared drying or oven drying, etc., preferably in a manner that does not affect the performance of the functional layer during drying. The timing of the aforementioned drying treatment may be after the preparatory layer of on...

Embodiment 1-8

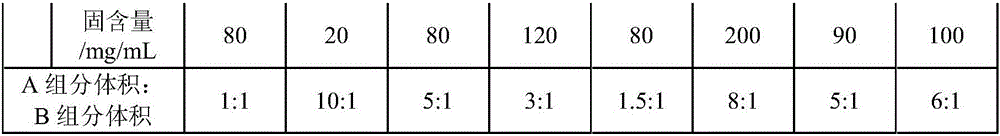

[0060] The functional materials in Examples 1-8 are all luminescent nanocrystals (red quantum dots, CdSe / ZnS with oleylamine ligands), and the types and amounts of components in the ink formulations of each example are as follows.

[0061] Table 1:

[0062]

[0063]

[0064] The ink formula inkjet printing (printer model is DMP2831) of above-mentioned each embodiment is on transparent glass substrate, uses Filmetrics F40 model machine to test film thickness, evenly gets nine positions to test, then calculates thickness uniformity=(Max-Min ) / (2Ave), and Ave=(d1+d2+d3+...+d8+d9) / 9, where Max refers to the value with the largest thickness among the 9 data, Min refers to the value with the smallest thickness, and Ave refers to each The average thickness of the point, d1, d2...d9 represent the thickness value of each point. The smaller the value of thickness uniformity, the more uniform the film thickness. The test results of the thickness uniformity of each embodiment are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com