Co-CoOx/NMC (nitrogen-doped mesoporous carbon supported cobalt-cobalt oxide) nanocomposite material and preparation method and application thereof

A nitrogen-doped mesoporous carbon and nanocomposite technology is applied in the preparation/purification of carbon, cobalt oxide/cobalt hydroxide, nanotechnology, etc. It can improve the performance of electrocatalytic oxygen reduction, easy operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

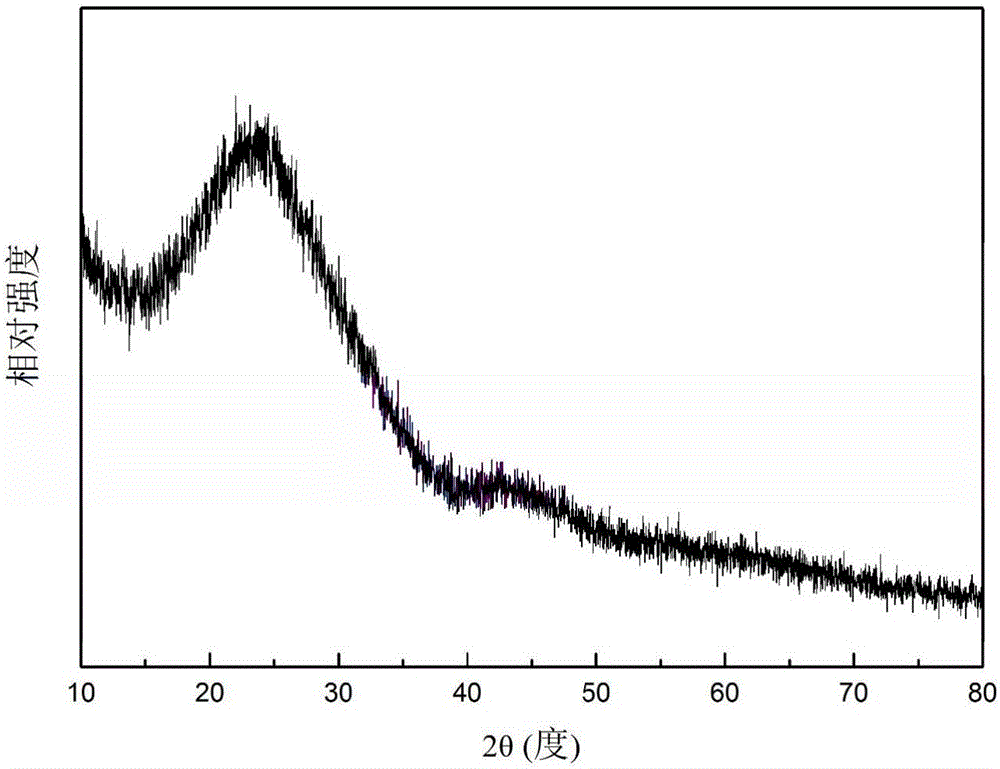

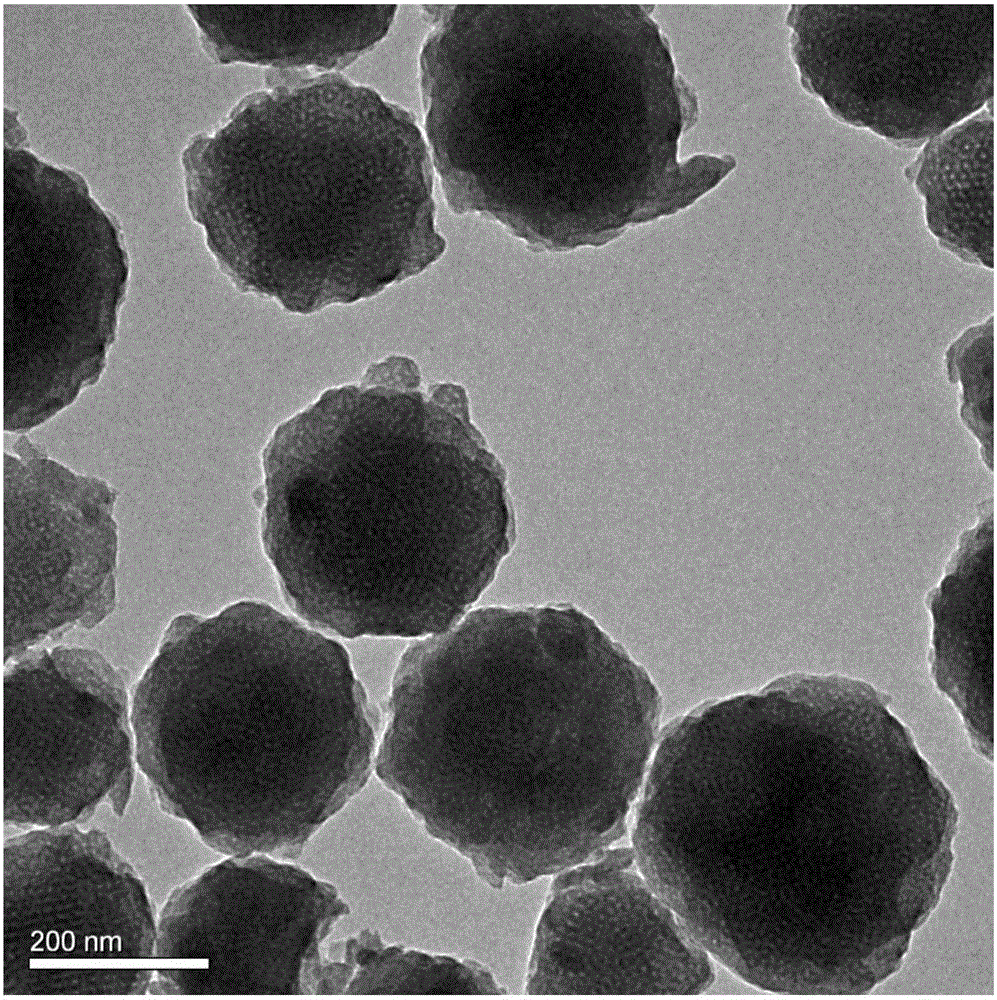

[0034] At room temperature, fully dissolve 0.24mmol triblock copolymer F127, 10mmol 3-aminophenol, 5mmol urotropine and 19mmol ammonia water in 52ml of water, stir well, heat in an oil bath at 80°C, condense and reflux and stir for 24h to make it Fully polymerize; naturally cool down after polymerization, settle, wash with water to collect the product, and dry overnight in a vacuum oven at 40°C; after drying, heat up to 350°C at a heating rate of 1°C / min for calcination in a high-temperature tube furnace under an Ar gas atmosphere 1h, then raised to 600°C at the same heating rate and then calcined for 3h, and the mesoporous carbon was obtained after natural cooling, denoted as NMC-600 (see figure 1 with 2 ).

[0035] Depend on figure 1 with 2 It can be seen that the mesoporous carbon NMC-600 is an amorphous material with a spherical shape and a uniform mesoporous structure.

Embodiment 2

[0037] At room temperature, fully dissolve 0.24mmol triblock copolymer F127, 10mmol 3-aminophenol, 5mmol urotropine, 0.6mmol Co(NO 3 ) 2 ·6H 2O and 19 mmol of ammonia water, stirred thoroughly, heated in an oil bath at 80°C, condensed and refluxed and stirred for 24 hours to fully polymerize; after polymerization, the temperature was naturally lowered, the product was collected by sedimentation, washed with water, and dried overnight in a vacuum oven at 40°C; after drying In a high-temperature tube furnace under an Ar gas atmosphere, heat up to 350°C at a rate of 1°C / min for calcination for 1 hour, then raise the temperature to 600°C for 3 hours at the same rate, and then naturally cool down to obtain nitrogen-doped mesoporous carbon Loaded cobalt-cobalt oxide nanocomposites, denoted as Co-CoO x -1 / NMC-600 (see image 3 with 4 ).

[0038] Depend on image 3 It can be seen that the composite Co-CoO x The characteristic diffraction peaks of Co and CoO appeared in the XRD ...

Embodiment 3

[0040] At room temperature, fully dissolve 0.24mmol triblock copolymer F127, 10mmol 3-aminophenol, 5mmol urotropine, 1.2mmol Co(NO 3 ) 2 ·6H 2 O and 19 mmol of ammonia water, stirred thoroughly, heated in an oil bath at 80°C, condensed and refluxed and stirred for 24 hours to fully polymerize; after polymerization, the temperature was naturally lowered, the product was collected by sedimentation, washed with water, and dried overnight in a vacuum oven at 40°C; after drying In a high-temperature tube furnace under an Ar gas atmosphere, the temperature was raised to 350°C for 1 hour at a heating rate of 1°C / min, and then calcined for 3 hours at the same heating rate to 600°C, and nitrogen-doped mesoporous pores were obtained after natural cooling. Carbon-supported cobalt-cobalt oxide nanocomposites, denoted as Co-CoO x -2 / NMC-600 (see Figure 5 , 6 , 7, 8 and 9).

[0041] Depend on Figure 5 It can be seen that the composite Co-CoO x The characteristic diffraction peaks o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com