System and method for treating titanium dioxide molten salt chlorination waste salt

A technology of molten salt chlorination and titanium dioxide, applied in the chemical industry, can solve problems such as environmental pollution, unfavorable resource utilization level, soil and water pollution, etc., and achieve the effects of simple and easy operation, efficient recovery, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

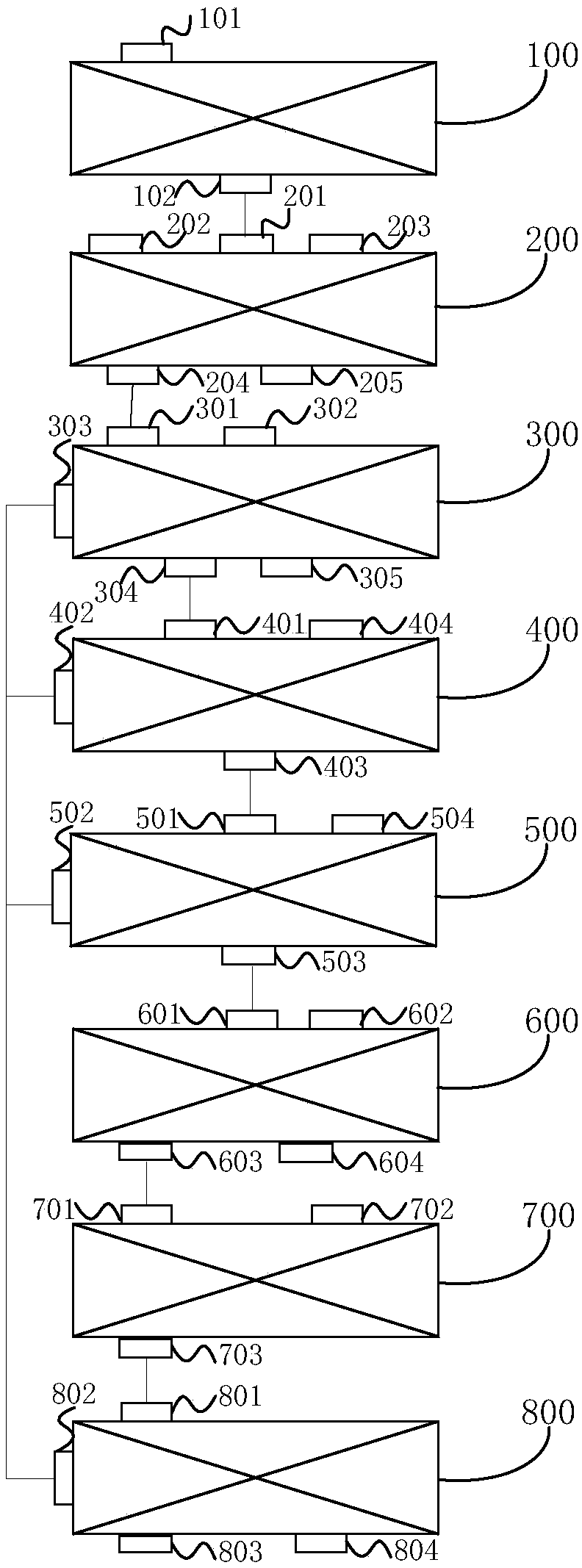

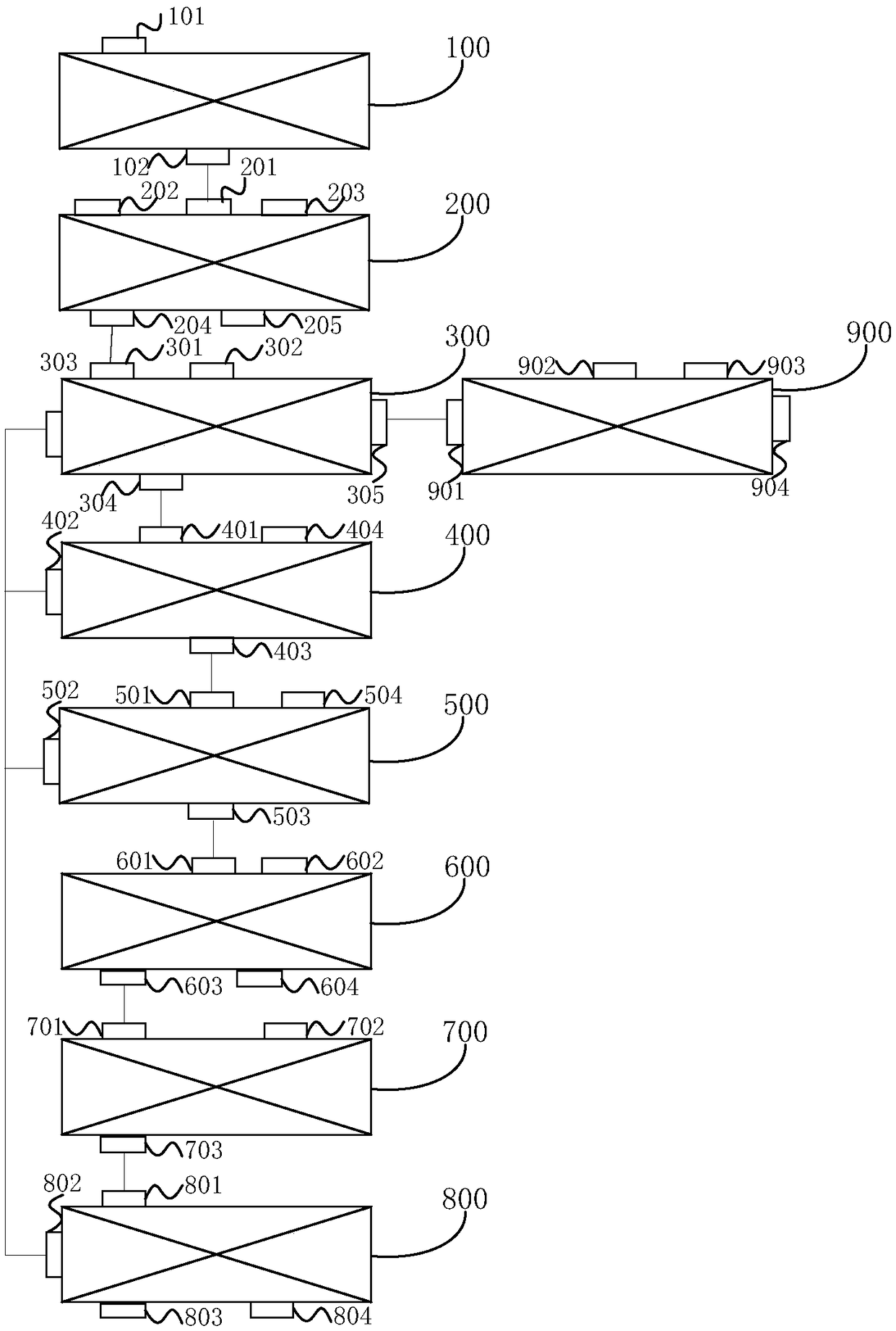

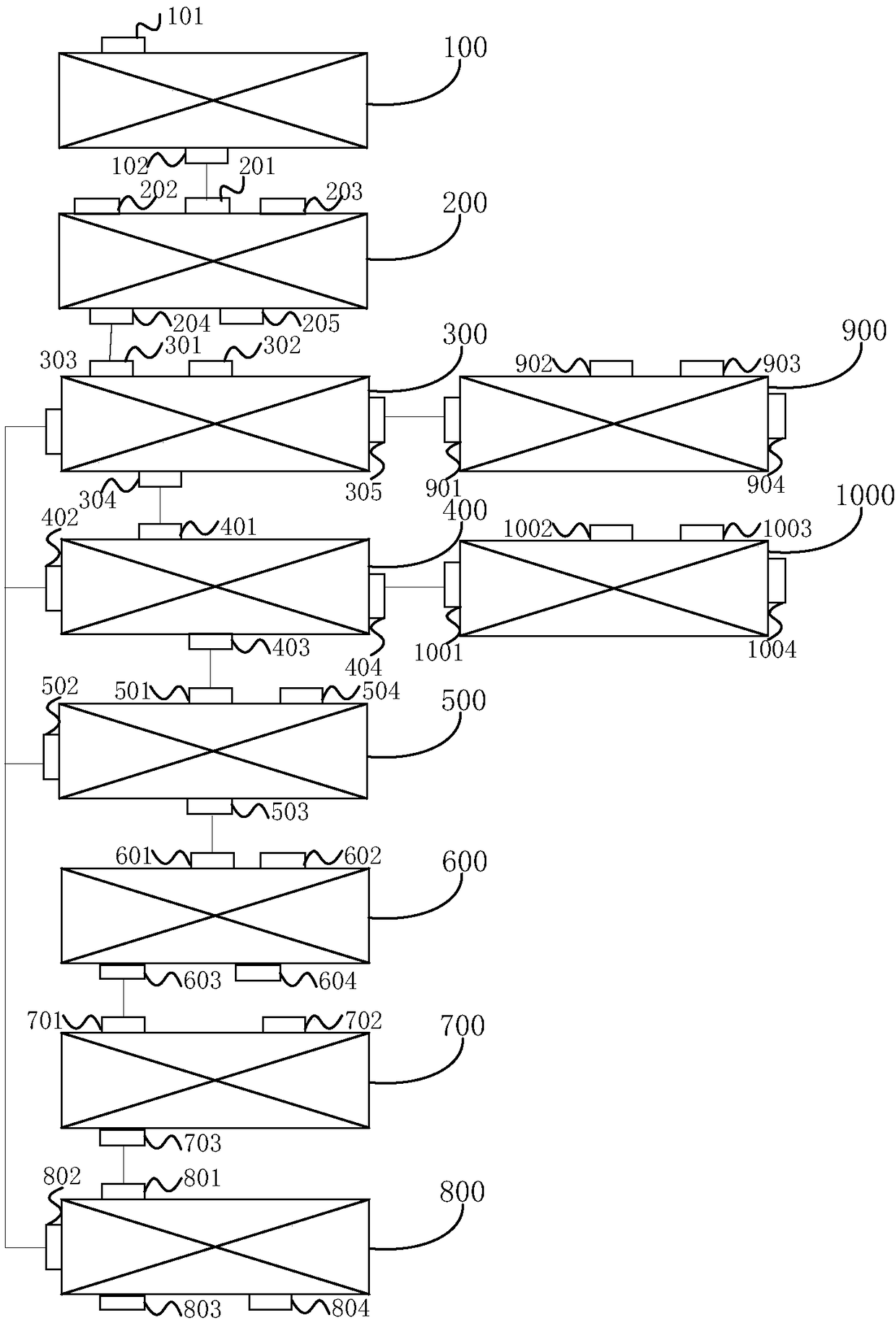

Image

Examples

Embodiment 1

[0157] (1) Crushing: the titanium dioxide molten salt chlorination waste salt is crushed to obtain titanium dioxide molten salt chlorination waste salt particles with a particle size of less than 80 mesh.

[0158] (2) Acid dissolution-separation: water and titanium dioxide molten salt chlorination waste salt particles are mixed according to the liquid-solid volume mass ratio of 1:4, and the composition of the obtained titanium dioxide molten salt chlorination waste salt solution is shown in Table 2, and to Hydrochloric acid is added to adjust the pH of the solution to 2, the stirring speed is 20-600r / min, and the time is 30-120min to obtain 100L of the first filtrate and filter residue.

[0159] (3) Heavy iron-filtering: the first filtrate is heated to 80 degrees Celsius, and 1.2 times the theoretical amount of MnO is added thereto 2 , with a mass of 824.76g. The stirring speed is 200 revs / min, and the pH of the mixed solution is adjusted to 3.0 with a sodium hydroxide soluti...

Embodiment 2

[0168] (1) Crushing: the titanium dioxide molten salt chlorination waste salt is crushed to obtain titanium dioxide molten salt chlorination waste salt particles with a particle size of less than 80 mesh.

[0169] (2) Acid dissolution-separation: water and titanium dioxide molten salt chlorination waste salt particles are mixed according to the liquid-solid volume mass ratio 1:3, and the composition of the obtained titanium dioxide molten salt chlorination waste salt solution is shown in Table 3, and to Hydrochloric acid is added to adjust the pH of the solution to 2, the stirring speed is 20-600r / min, and the time is 30-120min to obtain 100L of the first filtrate and filter residue.

[0170] (3) Heavy iron-filtering: the first filtrate is heated to 90 degrees Celsius, and 1.2 times the theoretical amount of MnO is added thereto 2 , with a mass of 719.61g. The stirring speed is 200 revs / min, and the pH of the mixed solution is adjusted to 3.0 with a sodium hydroxide solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com