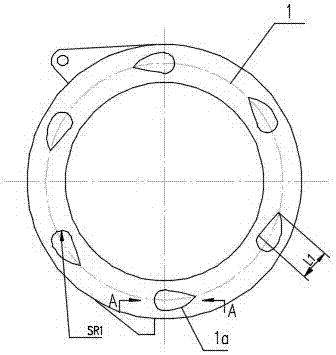

Quenching inductor for conical pit of brake disc and matched application size determining method

A technology for quenching inductors and brakes, which is applied in the field of brake pressure plate cone sockets, quenching inductors and matching dimensions, which can solve the problems of unsatisfactory heating effect and poor profiling, and achieve simple and feasible matching methods and good profiling Improve performance and ensure heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0058] The quenching inductor used for the cone socket of the brake pressure plate is made of pure copper, and its components include: the heating coil 2a in the quenching inductor 2, the left square tube 2b, the right square tube 2c, the left round tube 2d and the right circle The tube 2e has five parts, each of which is a hollow pure copper tube; the water inlet end of the left square tube 2b is welded vertically with the water outlet end of the left circular tube 2d, and the water outlet end is welded horizontally with the water inlet of the heating coil 2a , the water outlet end of the right square mouth pipe 2c is welded vertically with the water inlet end of the right round pipe 2e, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com