Method for producing succinic acid through polypropylene nonwoven fabric immobilized Actinobacillus succinogenes fermentation

A polypropylene non-woven fabric, actinomycetes technology, applied in the field of bioengineering, can solve the problems of difficult to reuse bacteria, the conversion rate is only 65%, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1 batch fermentation

[0016] Take the gram weight as 15g / m 2 Polypropylene melt-blown non-woven fabric, sterilized at 121°C for 20min. Actinobacillus succinogenes A.succinogenes CCTCC NO:M2012036 Shake flask seeds in CO 2 Cultivate in the atmosphere for 12 hours, the culture temperature is 38°C, insert the seeds of Actinobacillus succinicum shake flask into 25mL seed medium according to the inoculum size of 3%, at 35°C, pass CO 2 After cultivating under anaerobic conditions for 3 hours, put the non-woven fabric into the seed medium and continue the adsorption culture for 3 hours. Seed medium contains glucose 8-12g / L, yeast extract 10-14g / L, K 2 HPO 4 15—17g / L, NaH 2 PO 4 5-7g / L, natural pH, sterilized at 115°C for 20min.

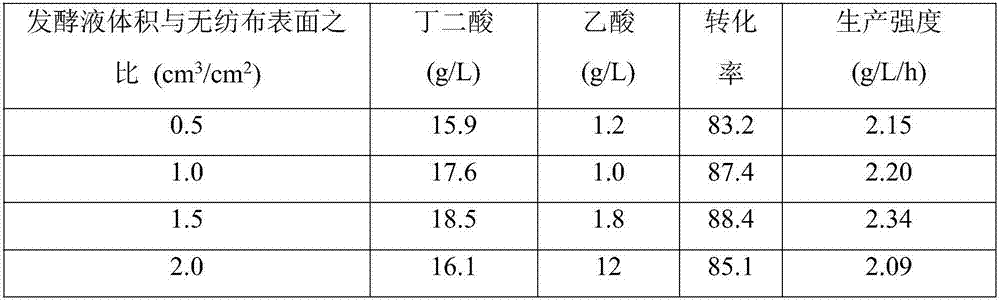

[0017] After the adsorption culture of Actinobacillus succinate, put the non-woven fabric immobilized with Actinobacillus succinate into the shake flask with fresh fermentation medium, the ratio of the volume of the fermentation liq...

Embodiment 2

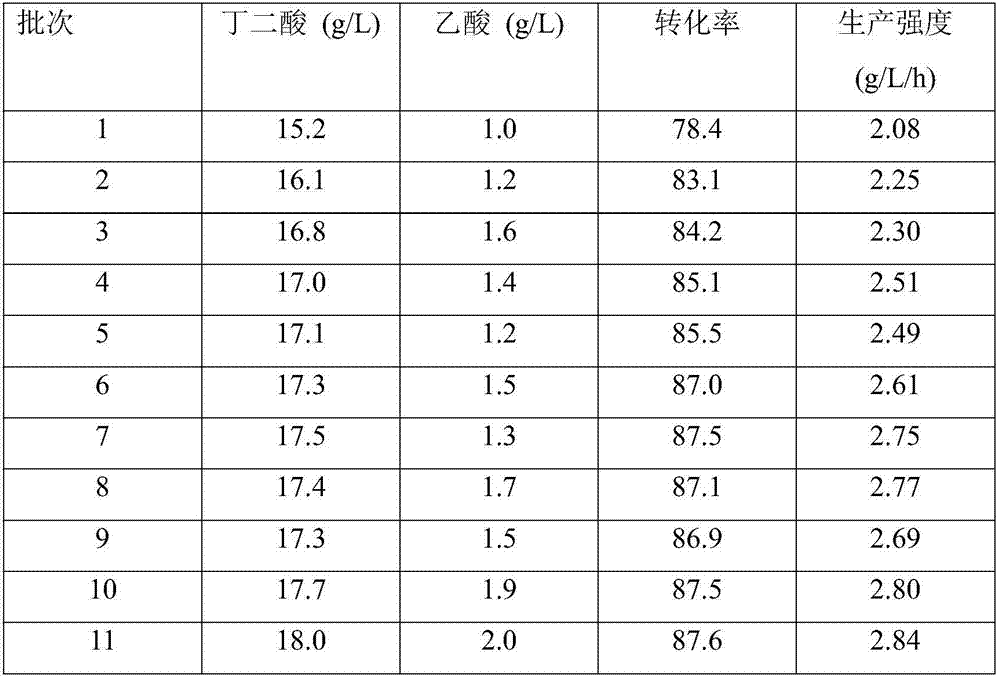

[0020] Embodiment 2 Batch fermentation repeatedly

[0021] With reference to the method of embodiment 1, carry out repeated batch fermentation experiment. The ratio of the volume of the fermentation broth to the surface of the non-woven fabric is 1.0cm 3 / cm 2 , the initial sugar concentration was 20g / L, and the acid production was measured by sampling every 3h. When the glucose concentration in the fermentation broth was lower than 5g / L, the average fermentation time was 15h. The fresh fermentation medium was replaced, and the next batch of fermentation was repeated. The fermentation batch was repeated 11 times, and the total running time was 120 hours. The results are shown in Table 2. According to the results in the table, it was found that with the increase of fermentation batches, the yield of succinic acid tended to increase.

[0022] Table 2 Reactor repeated batch fermentation to produce succinic acid

[0023]

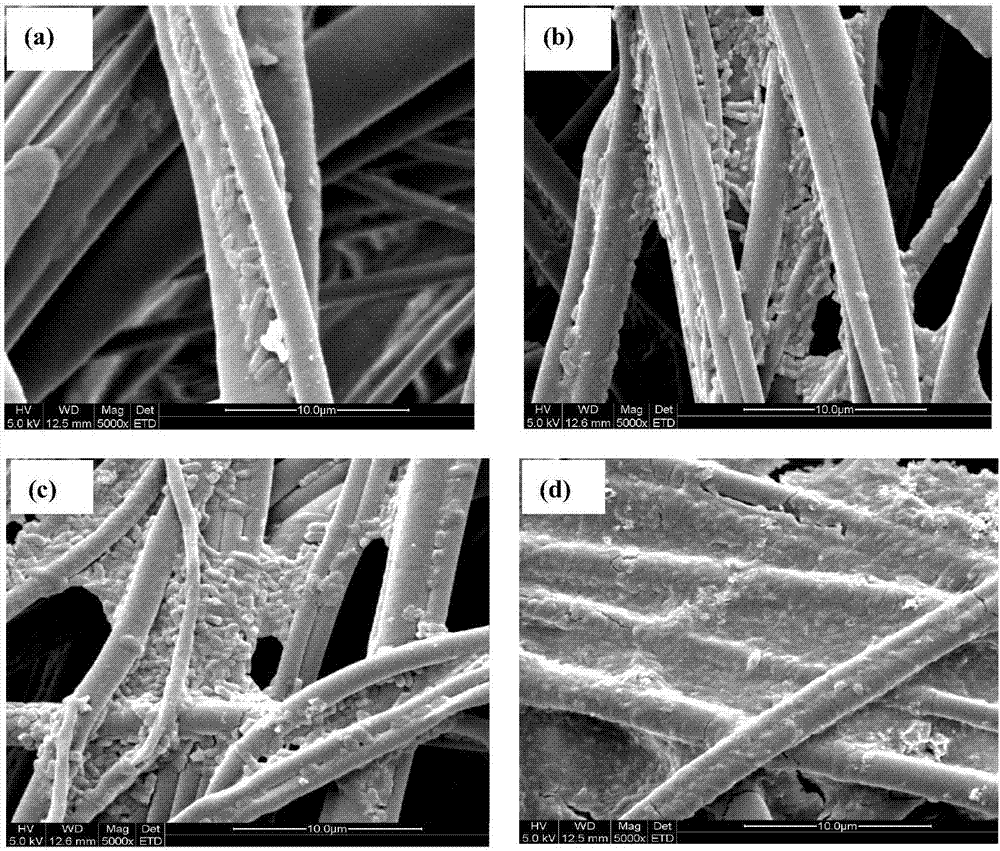

[0024] The morphology of Actinobacillus succinicum ...

Embodiment 3

[0025] The influence of embodiment 3 fermented liquid glucose concentration produces succinic acid by fermentation

[0026] The batch fermentation experiment was carried out with reference to the method of Example 1. The ratio of the volume of the fermentation broth to the surface of the non-woven fabric is 1.0cm 3 / cm 2 , the initial sugar concentration was 10-30g / L, and the acid production was measured by sampling every 3 hours. When the glucose in the fermentation liquid was consumed, the fermentation was terminated. The results are shown in Table 3.

[0027] Table 3 The influence of the concentration of glucose in the fermentation liquid on the production of succinic acid by fermentation

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com