Halogen-free flame retardation and smoke suppression asphalt and production method thereof

A technology of asphalt and modified asphalt, applied in building components, building insulation materials, construction and other directions, can solve the problems of inability to improve the conventional performance of asphalt, unfavorable durability of asphalt pavement, large amount of flame retardants, etc., and achieve good environmental protection. effect, excellent flame retardant and smoke suppression effect, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

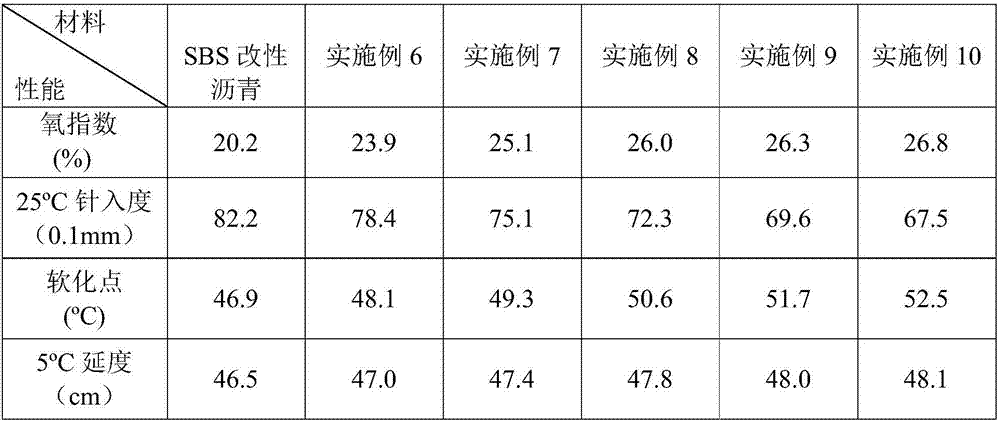

Examples

preparation example Construction

[0030] A preparation method of halogen-free flame-retardant smoke-suppressing pitch; specifically comprising the following steps:

[0031] 1), firstly mix distilled water, attapulgite and organic reagent according to the proportion at 70-80°C to obtain mixture A;

[0032] 2), then add coupling agent to mixture A, and obtain mixture B after stirring evenly;

[0033] 3), then the mixture B is naturally cooled, vacuum filtered and washed until no bubbles are generated in the extracted liquid, then dried, ground and passed through a 200-mesh sieve to obtain the organic attapulgite;

[0034] 4) After heating the asphalt to a molten state, add organic attapulgite and dispersant in turn at a stirring speed of 1500-2500r / min, and then stir evenly to obtain mixture C;

[0035] 5) Add a defoamer to the mixture C and stir evenly to obtain a halogen-free flame-retardant and smoke-suppressing asphalt.

[0036] Specifically, in step 1) and step 2), the mixture is obtained after stirring a...

Embodiment 1

[0040] Step 1. Take 100g of distilled water, 10g of attapulgite and 1.4g of octadecyltrimethylammonium chloride and stir at 70°C for 1.5h at a rate of 400r / m to obtain mixture A;

[0041] Step 2: Add 0.05 g of silane coupling agent to mixture A, and continue stirring at the same rate as step 1 for 1.5 h to obtain mixture B;

[0042] Step 3. After the mixture B is cooled, perform vacuum filtration and water washing until no air bubbles are generated in the extracted liquid, then perform drying treatment, and then grind and pass through a 200-mesh sieve to obtain an organic attapulgite;

[0043] Step 4: Heat 200g of SK90# base asphalt to 150°C to a molten state, then add 2g of organic attapulgite and 0.02g of sodium dodecylbenzenesulfonate at a stirring rate of 2000r / m, and keep the temperature at 3000r / m Stir at a high speed for 20min to obtain mixture C;

[0044] Step 5: Add 0.01 g of polydimethylsiloxane to the mixture C and stir at a rate of 1000 r / m for 5 minutes to obtain...

Embodiment 2

[0046] Step 1. Take 150g of distilled water, 10g of attapulgite and 1.5g of octadecyltrimethylammonium chloride and stir at 80°C for 2.5h at a rate of 300r / m to obtain mixture A;

[0047] Step 2. Add 0.06 g of borate coupling agent to mixture A, and continue stirring for 1 h at the same rate as step 1 to obtain mixture B;

[0048]Step 3. After the mixture B is cooled, perform vacuum filtration and water washing until no air bubbles are generated in the extracted liquid, then perform drying treatment, and then grind and pass through a 200-mesh sieve to obtain an organic attapulgite;

[0049] Step 4: Heat 200g of SK90# base asphalt to 150°C to a molten state, then add 4g of organic attapulgite and 0.06g of sodium lauryl sulfate at a stirring rate of 2000r / m, and keep stirring at a rate of 3000r / m at this temperature 20min, obtain mixture C;

[0050] Step 5: Add 0.03 g of polyoxypropylene into the mixture C and stir for 5 min at a rate of 1000 r / m to obtain organic attapulgite-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com