Scale remover and preparation method thereof

A technology of descaling agent and control unit, applied in the field of descaling agent and its preparation, can solve the problems of secondary pollution of water body, poor descaling effect, polluted environment, etc., and achieve multiple coordination points and strong chelating ability , the effect of wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A detailed description will be given below in conjunction with the accompanying drawings.

[0038] The present invention provides a descaling agent formed by injecting at least one component material of the descaling agent into a well through a descaling agent injection device and mixing them. The component substances of the present invention include single substances and mixtures of at least two mutually nonreactive substances. Preferably, the mixture is formed by mixing at least two mutually non-reactive substances according to a certain mass ratio.

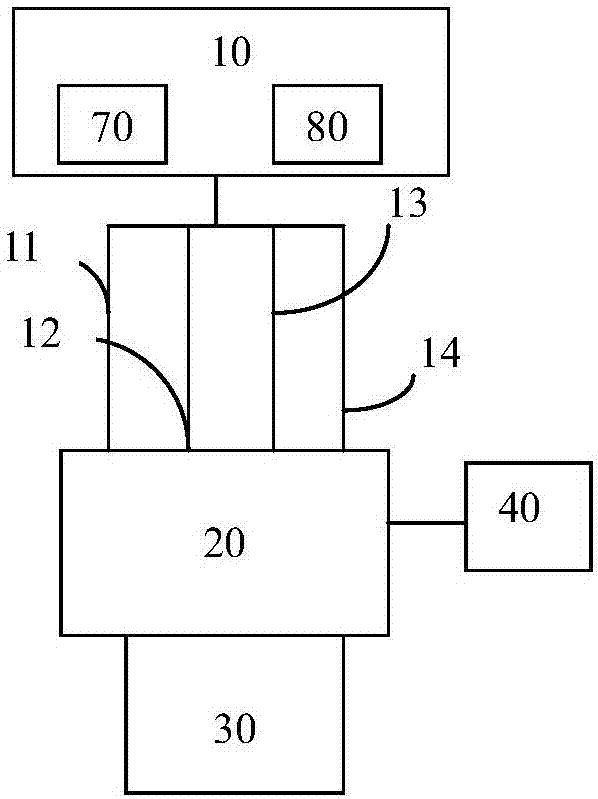

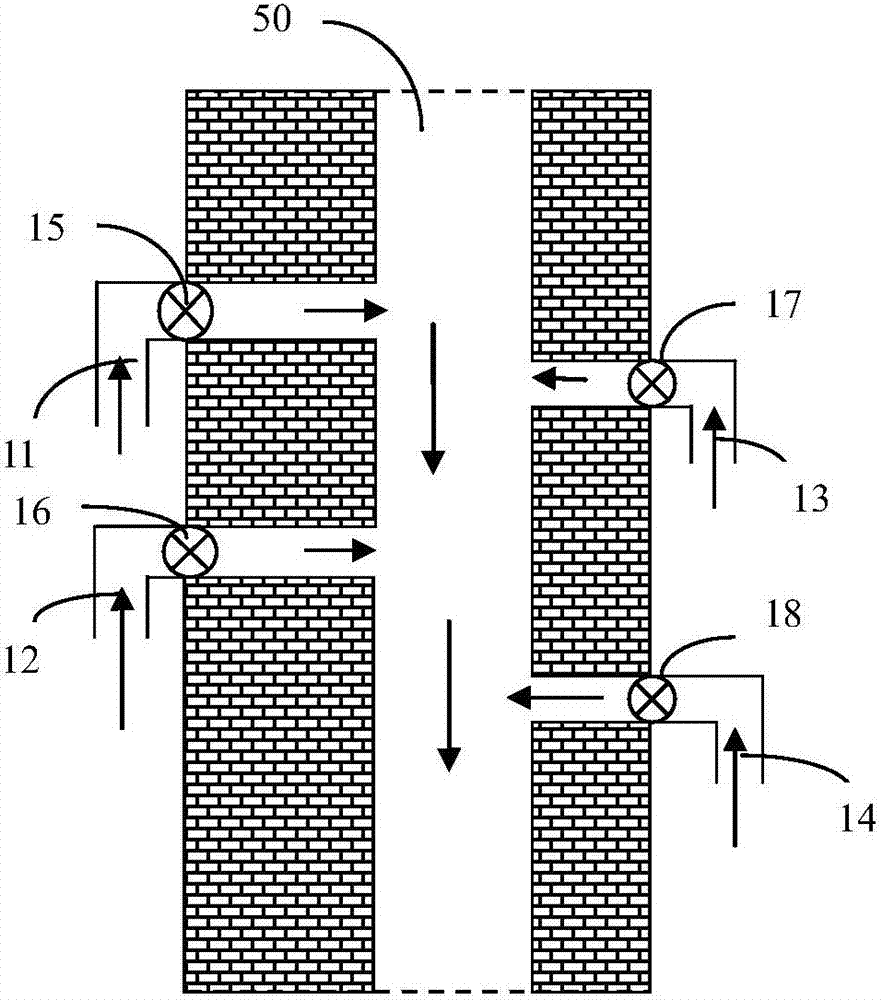

[0039] Such as figure 1 As shown, the descaling agent injection device of the present invention includes an input unit 10 , an injection unit 20 and a control unit 40 . The injection unit 20 is coupled with the wellhead 30 of the oil well. The control unit 40 is connected with the pressure device 70 and the trigger device 80 in a wired or wireless manner.

[0040] The feed unit 10 serves to feed at least one componen...

Embodiment 2

[0061] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

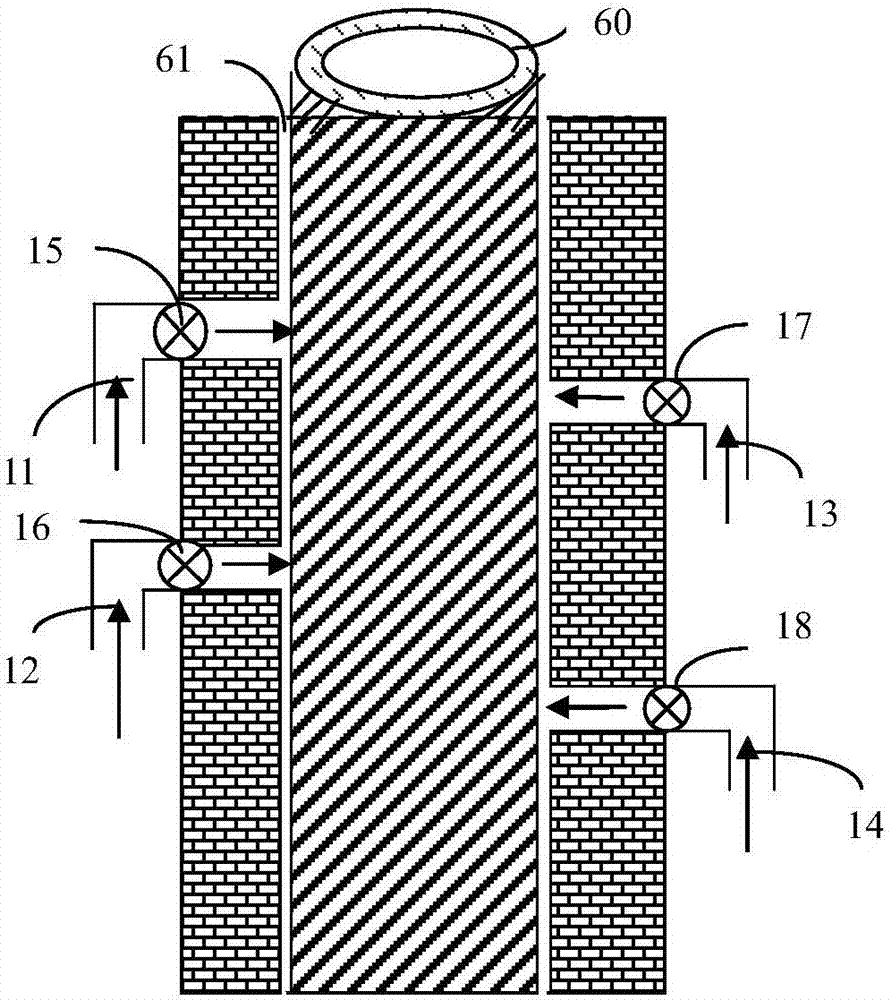

[0062] Such as image 3 As shown, the main channel 50 of the present invention is provided with a polymerization tube 60 . The main channel 50 is a cylindrical pipe, and the polymer tube 60 is cylindrical with inclined threads distributed on the outer surface. Preferably, the radius of the polymerization tube 60 is smaller than the radius of the main channel 50 . The space between the polymer tube 60 and the hole wall of the main channel 50 forms an annular space 61 . The annular space builds up to a certain pressure as the input line feeds the pressurized component material into the annular space. At least one component substance is sprayed on the surface of the polymer tube at a specified flow rate by the choke valve, and under the pressure of the annular space 61, flows along the inclined thread and uniformly gathers and mixes.

[0063] A pressure collectio...

Embodiment 3

[0074] This embodiment is a further improvement on Embodiment 1 and Embodiment 2, and repeated content will not be repeated here.

[0075] The invention provides a descaling method, which is characterized in that the descaling method is to inject at least one descaling agent component into the oil and gas well through a descaling agent injection device in a time-sharing and asynchronous manner, and the descaling agent The injection device at least includes an input unit, an injection unit and a control unit, and the injection unit coupled with the wellhead includes a main channel and at least one component for injecting the descaling agent and is provided with a flow characteristic according to the component The input pipe of the choke valve whose parameters control the injection rate and injection angle of the component, the control unit dynamically adjusts the flow characteristic parameters connected to the The input pressure of at least one input line between the input unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com