Method for preparing sheet Bi2WO6

A flake and solution technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, tungsten compounds, etc., can solve the problems of low proportion and low photocatalytic reaction efficiency, and achieve no environmental pollution , Simple process, good dispersion of powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Dissolve 1.5mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.10mol / L;

[0036] 2) 3mmol bismuth ammonium citrate is dissolved in 15ml deionized water, so that the molar concentration of bismuth ammonium citrate solution is 0.20mol / L, a certain amount of NaOH tablet is dissolved in 10ml deionized water, so that the sodium hydroxide solution molar concentration 0.4mol / L;

[0037] Add the ammonium bismuth citrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the sodium hydroxide solution dropwise to the above mixed solution at the same rate, and stir for 30 minutes, then at 180 ℃ for 2 hours for heat treatment. Then, lower to room temperature, take out the reaction product, filter, wash with dilute acetic acid and deionized water successively, and dry at 60°C to obtain flaky Bi 2 WO 6 .

Embodiment 2

[0039] 1) Dissolve 3mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.20mol / L;

[0040] 2) 6mmol bismuth ammonium citrate is dissolved in 15ml deionized water, so that the molar concentration of bismuth ammonium citrate solution is 0.40mol / L, a certain amount of NaOH tablet is dissolved in 10ml deionized water, so that the sodium hydroxide solution molar concentration 0.8mol / L;

[0041] Add the ammonium bismuth citrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the sodium hydroxide solution dropwise to the above mixed solution at the same rate, and stir for 30 minutes, then at 200 ℃ for 6 hours to heat treatment. Then, after cooling down to room temperature, the reaction product was taken out, filtered, washed three times with dilute acetic acid, deionized water and ethanol, and dried at 60°C to obtain flaky Bi 2 WO 6 .

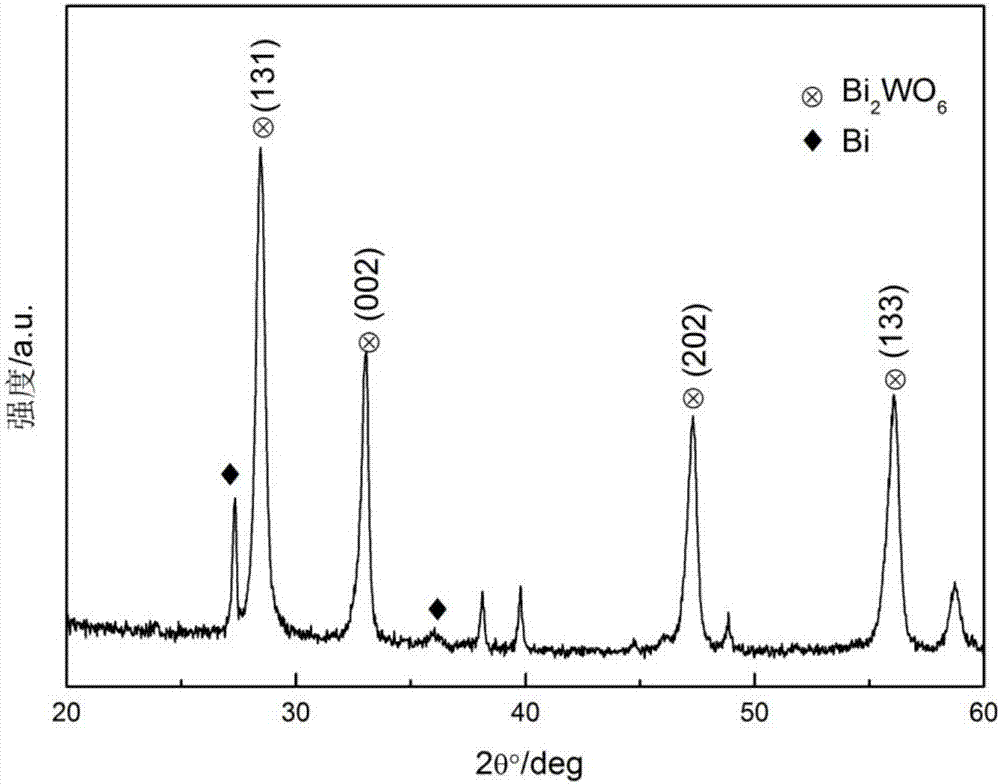

[0042] The synthesized fl...

Embodiment 3

[0044] 1) Dissolve 4.5mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.30mol / L;

[0045] 2) 9mmol bismuth ammonium citrate is dissolved in 15ml deionized water, so that the molar concentration of bismuth ammonium citrate solution is 0.60mol / L, a certain amount of NaOH tablet is dissolved in 10ml deionized water, so that the sodium hydroxide solution molar concentration 2mol / L;

[0046] Add the bismuth ammonium citrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the sodium hydroxide solution dropwise to the above mixed solution at the same rate, and stir for 30 minutes, then at 250 ℃ for 15 hours for heat treatment. Then, after cooling down to room temperature, the reaction product was taken out, filtered, washed three times with dilute acetic acid, deionized water and ethanol, and dried at 60°C to obtain flaky Bi 2 WO 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com