Carbon fiber supported CoWP catalyst and preparation method

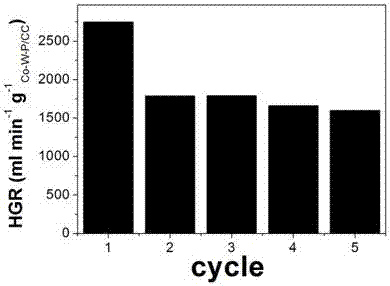

A carbon fiber and catalyst technology, applied in the field of hydrogen energy and fuel cells, can solve the problems of high energy consumption and high cost, and achieve the effects of high hydrogen production rate, stable performance and dense distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

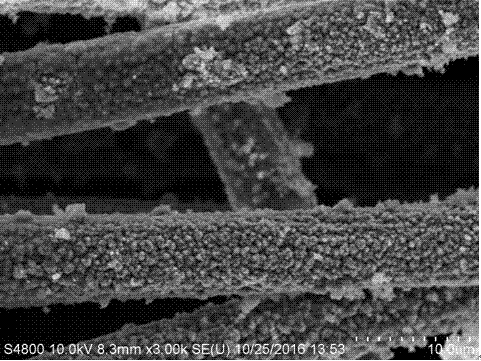

[0033] Soak the carbon fiber cloth in absolute ethanol, vibrate ultrasonically at 25°C for 10 min, and then immerse in 0.01 M hydrochloric acid for 5 min with magnetic stirring. Wash with deionized water and ultrasonic vibration for 10 min.

[0034] In electrodeposition 1, the carbon fiber is impregnated in a mixed solution of cobalt chloride and boric acid, and the electrodeposition is carried out at a temperature of 40°C and a current density of 900mA / cm2 for 10, 20, 30, and 40mins. The carbon fiber is taken out and rinsed with deionized water.

[0035] Immerse the electrodeposited carbon fiber in cobalt chloride solution for 2.5 hours.

[0036] Immerse the carbon fiber in a mixed solution of 0.05M sodium tungstate and 0.1M sodium hypophosphite, conduct electrodeposition at a temperature of 50°C and a current density of 600mA / cm2 for 10 minutes, take out the carbon fiber, rinse it with deionized water and absolute ethanol.

[0037] Put the electrodeposited carbon fiber into...

Embodiment 2

[0039] Soak the carbon fiber cloth in absolute ethanol, vibrate ultrasonically at 25°C for 10 min, and then immerse in 0.01 M hydrochloric acid for 5 min with magnetic stirring. Wash with deionized water and ultrasonic vibration for 10 min.

[0040] In electrodeposition 1, the carbon fiber was impregnated in a mixed solution of cobalt chloride and boric acid at a temperature of 40°C and the current density was 300, 500, 700, and 900mA / cm2 for 20mins. The carbon fiber was taken out and rinsed with deionized water.

[0041] Immerse the electrodeposited carbon fiber in cobalt chloride solution for 2.5 hours.

[0042] Immerse the carbon fiber in a mixed solution of 0.05M sodium tungstate and 0.1M sodium hypophosphite, conduct electrodeposition at a temperature of 50°C and a current density of 600mA / cm2 for 10 minutes, take out the carbon fiber, rinse it with deionized water and absolute ethanol.

[0043] Put the electrodeposited carbon fiber into a drying oven at 50°C for 12 hour...

Embodiment 3

[0045] Soak the carbon fiber cloth in absolute ethanol, vibrate ultrasonically at 25°C for 10 min, and then immerse in 0.01 M hydrochloric acid for 5 min with magnetic stirring. Wash with deionized water and ultrasonic vibration for 10 min.

[0046] In electrodeposition 1, the carbon fiber was impregnated in a mixed solution of cobalt chloride and boric acid at a temperature of 40°C and a current density of 900mA / cm2 for 20mins. The carbon fiber was taken out and rinsed with deionized water.

[0047] The carbon fiber after electrodeposition 1 was immersed in cobalt chloride solution for 0.5, 1, 1.5, 2, 2.5 hours.

[0048] Immerse the carbon fiber in a mixed solution of 0.05M sodium tungstate and 0.1M sodium hypophosphite, conduct electrodeposition at a temperature of 50°C and a current density of 600mA / cm2 for 10 minutes, take out the carbon fiber, rinse it with deionized water and absolute ethanol.

[0049] Put the electrodeposited carbon fiber into a drying oven at 50°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com