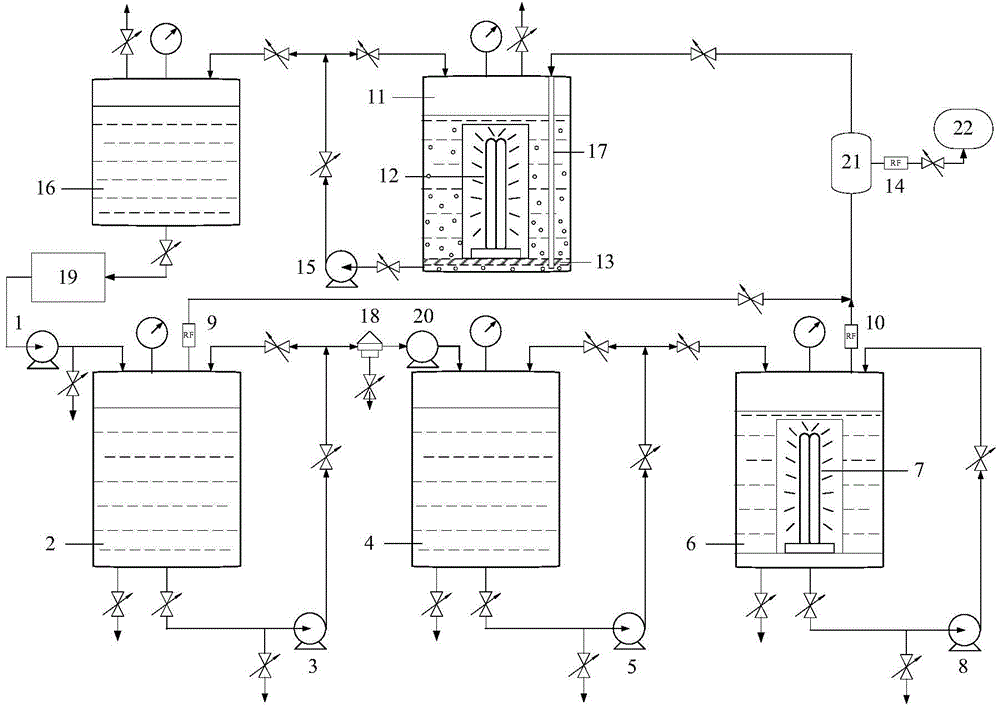

Low-carbon zero-emission circulating hydrogen preparing device

A hydrogen and gas separation technology, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve problems such as low hydrogen production efficiency, reduce pollutant emissions, and improve overall hydrogen production. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, the present invention will be explained in detail.

[0066] The pretreatment equipment of the device of the present invention can carry out the operation of centrifugation, heat drying and crushing, and the centrifugal device is preferably a centrifuge, the heating and drying device is preferably a high-temperature oven, and the crushing device is a grid, a crusher, a powder mill One or more combinations of machine and grit chamber, preferably a pulverizer.

[0067] The dark fermentation reactor in the device of the present invention is a conventional reactor of the prior art, such as plug flow reactor (PFR), complete mixing reactor (CSTR), anaerobic contact reactor (ACR), upflow anaerobic reactor, etc. Oxygenated sludge bed (UASB), upflow solids reactor (USR), expanded granular sludge bed (EGSB), internal circulation anaerobic reactor (IC), external circulation anaerobic reactor (EC), anaerobic sequence Batch batch reactor (ASBR), baffled reactor (ABR), a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com