Preparation method and application of porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure photocatalytic material

A catalytic material, carbon nitride technology, applied in the direction of graphene, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low process yield, pollution cost, high cost, etc., and achieve low cost and high process efficiency. The effect of mild conditions and strong interfacial contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure photocatalytic material, comprising the following steps:

[0027] (1) Synthesis of GO

[0028] GO nanosheets were synthesized by a modified Hummer method using natural graphite powder. First, 1.25 g NaNO 3 and 2.5g of graphite powder were gradually dispersed in concentrated H 2 SO 4 (60mL) solution. The temperature of the mixture was kept at 0 °C, and 7.5 g of KMnO was added 4 Dissolved gradually, and the mixture was stirred at 30 °C for 6 h to allow oxidation. Next, the mixture was diluted with 230 mL of deionized water and stirred at 90 °C for 20 min. By adding 6mL H 2 o 2 Terminate the reaction to reduce residual KMnO 4 , and a bright yellow mixture was obtained after the reduction reaction. The mixture was washed with deionized water, and then solid GO nanosheets were isolated by freeze-drying.

[0029] (2) Synthesis of porous two-dimensional carbon n...

Embodiment 2 to 5

[0031] The amount of GO in step (2) was replaced by 0.005, 0.007, 0.013 and 0.016 g GO, respectively, to obtain the corresponding products.

[0032] Taking the product obtained in Example 1 as an example, the characterization results are as follows:

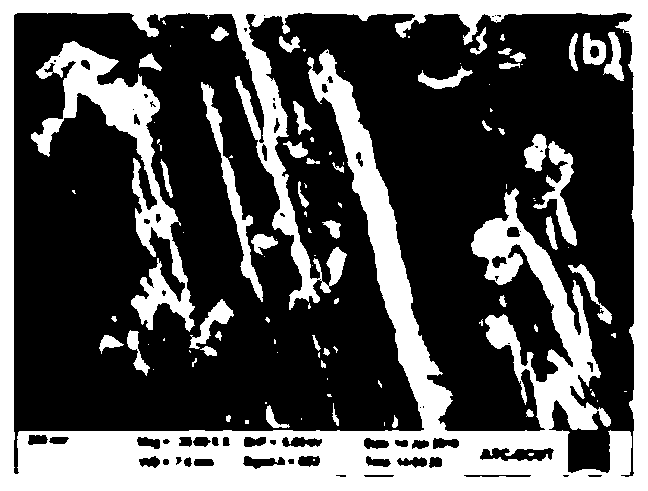

[0033] Depend on figure 1 and figure 2 It can be seen that the GOCN prepared in Example 1 is indeed a porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure.

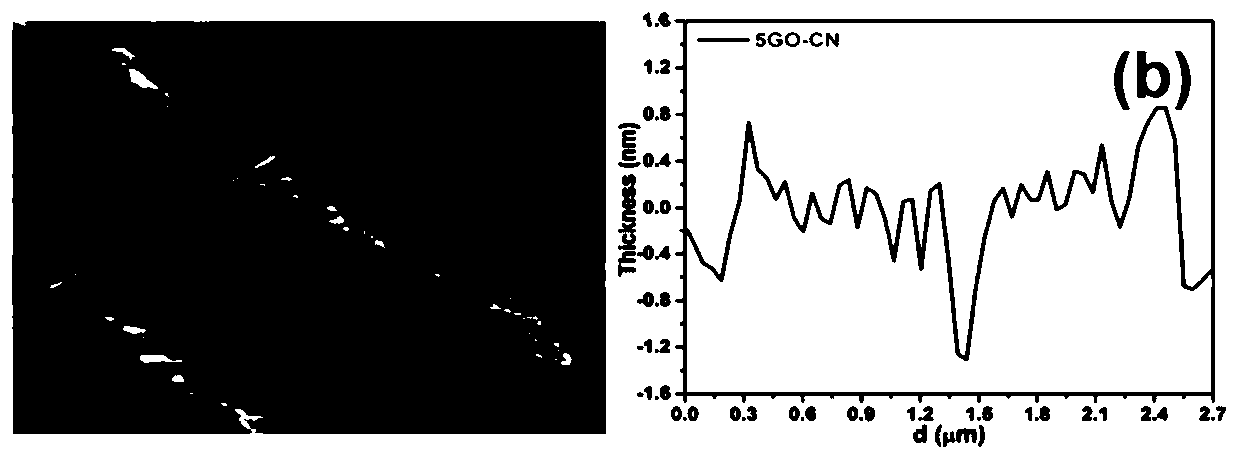

[0034] image 3 It is shown that GOCN is indeed a porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure, and the thickness of the outer carbon nitride layer in GOCN is about 0.5 nm, which is close to the monolayer thickness of CN. In addition, the thickness of the entire GOCN sample is about 1.6 nm, which can be concluded as an ultrathin structure.

[0035] The GOCN photocatalytic material and CN obtained in Example 1 of the present invention were used for the photocatalytic hydrogen production activity test. From ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com