Medicinal composition for treating Hashimoto's thyroiditis, and preparation method and use thereof

A technology of Hashimoto's thyroiditis, which is applied in the field of pharmaceutical composition and its preparation for the treatment of Hashimoto's thyroiditis, to achieve clear therapeutic effect and process economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

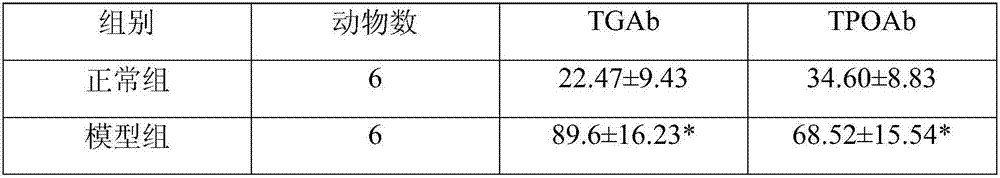

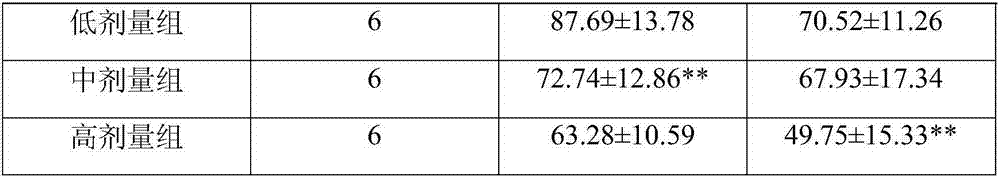

Examples

Embodiment 1

[0034] Example 1 The preparation of the polysaccharide extract of Trichosanthes rind and dried fig (1)

[0035] Take 100g of trichosanthes peel and 500g of dried figs, crush them, add 3L of ethyl acetate to soak for 12 hours; discard the organic solvent, add 1.3L of water to the dregs, boil for 2 hours, extract twice, filter and combine Filtrate; use a thin film evaporator to concentrate the water extract to 600ml, set the temperature to 60°C, and use the concentrated solution for later use; add 1.5L of 80% ethanol to the concentrated solution, and let it stand at 25°C to precipitate the crude polysaccharide, and filter to obtain the crude polysaccharide. Cake 8.6g; add 200ml of water to dissolve the filter cake, use the Servage method to deproteinize the crude polysaccharide of the filter cake (32ml chloroform / 8ml n-butanol), after mixing, centrifuge at a speed of 500g for 30min; combine the supernatants; then Dialyze with ordinary cellulose dialysis bags for 24 hours to remo...

Embodiment 2

[0036] The preparation of the polysaccharide extract of embodiment two Trichosanthes bark and dried fig (two)

[0037] Take 100g of Trichosanthes peel and 100g of dried figs, crush them, add 2L of dichloromethane to soak for 24 hours; discard the organic solvent, add 1L of water to the medicinal residue, boil for 3 hours, extract 3 times, filter, and combine the filtrates Concentrate the water extract to 300ml with a thin-film evaporator, set the temperature to 80°C, and use the concentrate for later use; add 1.2L of ethanol to the concentrate, let it stand at 4°C to precipitate the crude polysaccharide, filter to obtain 4.2g of crude polysaccharide filter cake Add 200ml of water to dissolve the filter cake, adopt the Servage method to deproteinize the crude polysaccharide of the filter cake (32ml chloroform / 8ml n-butanol), after mixing, centrifuge at a speed of 1000g, and centrifuge for 60min; merge the supernatant; The cellulose dialysis bag was dialyzed for 48 hours to remo...

Embodiment 3

[0038] Example 3 The preparation of the polysaccharide extract of Fructus Trichosanthes Peel and dried fig (three)

[0039]Take 20g of trichosanthes peel and 400g of dried figs, crush them, add 4.2L of ethanol aqueous solution (80%v / v-90%v / v) to soak for 12 hours; discard the organic solvent, add 1.5L of water to the medicinal residue , boiled and extracted for 4 hours, extracted twice, filtered, and combined filtrate; use a thin film evaporator to concentrate the water extract to 400ml, set the temperature to 75°C, and set the concentrate for use; add 1L of 90% ethanol to the concentrate, and stand at 4°C , make the crude polysaccharide separate out, filter, get the crude polysaccharide filter cake 12.4g; Add 600ml water to dissolve the filter cake, adopt Servage method to carry out deproteinization (96ml chloroform / 24ml n-butanol) to the filter cake crude polysaccharide, after mixing, centrifuge, Rotating speed is 800g, centrifugal 20min; Merge supernatant; Adopt common cell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com