Completely independent spring healthcare mattress

A completely independent, mattress technology, applied in the field of spring mattresses, can solve the problems of weakening the characteristics and functions of independent spring mattresses, restricting the independence and extensibility of springs, etc., achieving novel appearance, avoiding spring displacement, and structural unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

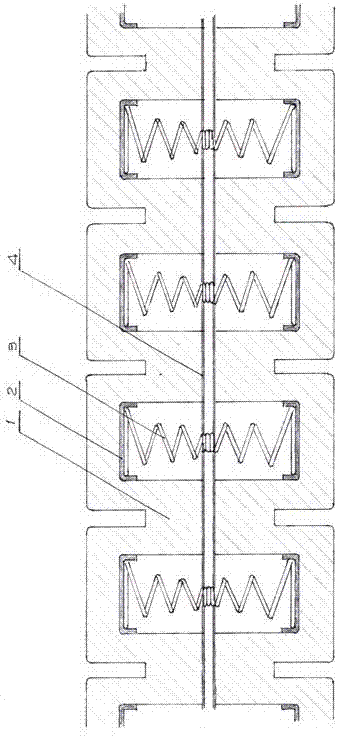

[0028] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0029] Such as image 3 The fully independent spring health mattress shown includes:

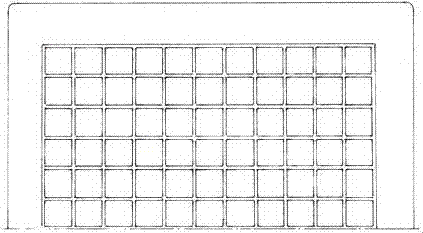

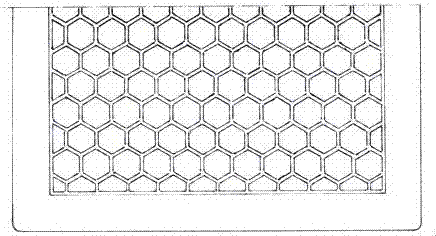

[0030] High-density sponge mattress base sheet 1: It is produced and processed by a cold-curing molding process. The isocyanate raw materials used in the cold-curing molding process are mainly TDI and MDI. If processing performance and foam properties need to be improved, TDI can be modified with trimers or urethanes. The more common method is to use 80 / 20TDI or MDI is used in combination, the temperature of the mold is controlled between 45 degrees and 55 degrees during production, and the post-curing stage needs to reach 11-12 hours to achieve the best performance. Figure 1~2 It is a schematic diagram of a regular quadrilateral column and a regular hexagonal column shape high-density sponge mattress substrate. The front of the high-density sponge mattress ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com