Chip for light-emitting diode and preparation method thereof

A technology of light-emitting diodes and chips, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as low reliability and easy breakage, and achieve the effects of improving reliability, enhancing stability, and avoiding electrode breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

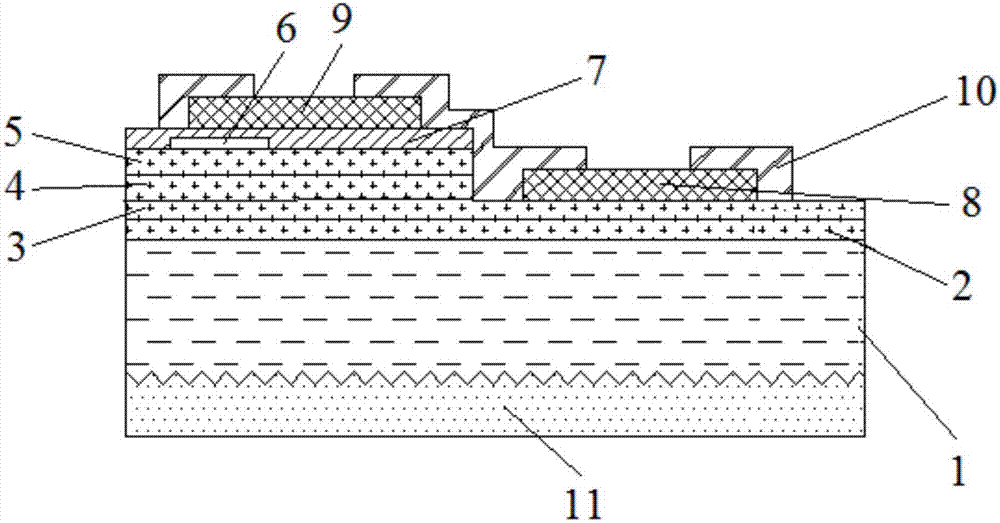

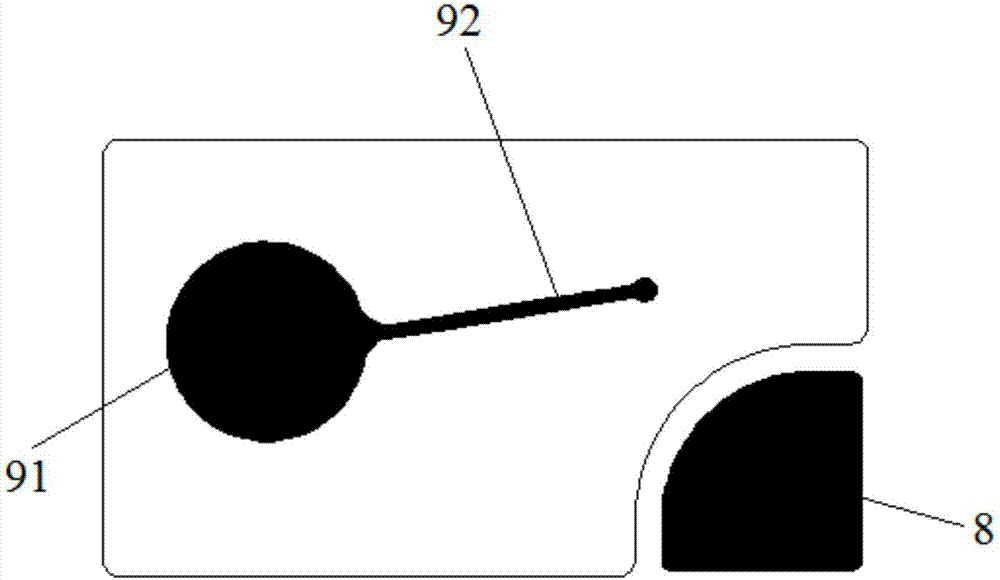

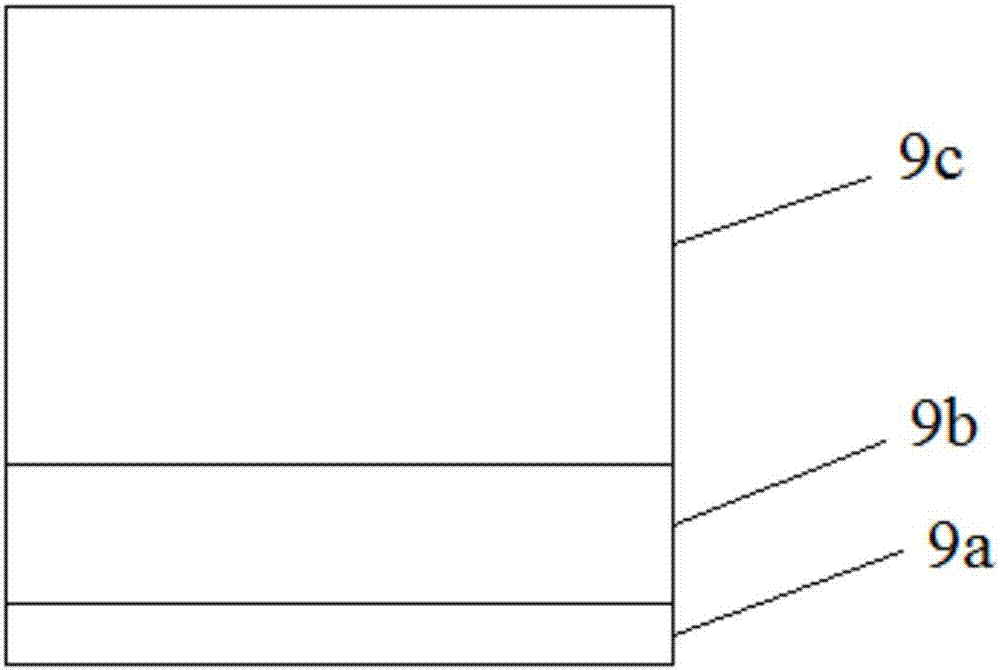

[0036] An embodiment of the present invention provides a light emitting diode chip, see figure 1 , the chip includes a substrate 1, and a gallium nitride buffer layer 2, an n-type gallium nitride layer 3, a multi-quantum well layer 4, a p-type gallium nitride layer 5, and a current blocking layer 6 stacked on the substrate 1 in sequence and a transparent conductive layer 7 , the chip is provided with grooves extending from the transparent conductive layer 7 to the N-type gallium nitride layer 3 . The chip also includes an N-type electrode 8, a P-type electrode 9 and a passivation layer 10. The N-type electrode 8 is arranged on the N-type gallium nitride layer 3 in the groove, and the passivation layer 10 is arranged on the transparent conductive layer 7, the concave On the sidewall of the groove and on the N-type gallium nitride layer 3 in the groove. The P-type electrode includes a cylinder whose bottom surface is arranged on the P-type gallium nitride layer and the transpar...

Embodiment 2

[0054] The embodiment of the present invention provides a method for preparing a light-emitting diode chip, which is suitable for preparing the chip provided in Embodiment 1, see Figure 4 , the preparation method comprises:

[0055] Step 201: sequentially growing a GaN buffer layer, an N-type GaN layer, a multi-quantum well layer, and a P-type GaN layer on the substrate.

[0056] Specifically, the substrate is a sapphire substrate. The multi-quantum well layer may include multiple indium gallium nitride layers and multiple gallium nitride layers, and the multiple indium gallium nitride layers and multiple gallium nitride layers are alternately stacked.

[0057] Step 202: Open a groove extending from the P-type GaN layer to the N-type GaN layer.

[0058] Step 203: forming a current blocking layer and a transparent conductive layer on the P-type GaN layer.

[0059] Specifically, the material of the current blocking layer may be silicon dioxide or aluminum oxide, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com