Forward and reverse rotation control and implementation method of Magnus effect vertical-axis wind turbine rotor

An implementation method and technology of wind turbines, applied in the control of wind turbines, engine control, wind turbines, etc., can solve the problems of large mechanical loss, large moment of inertia of cylinders, and difficult commutation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

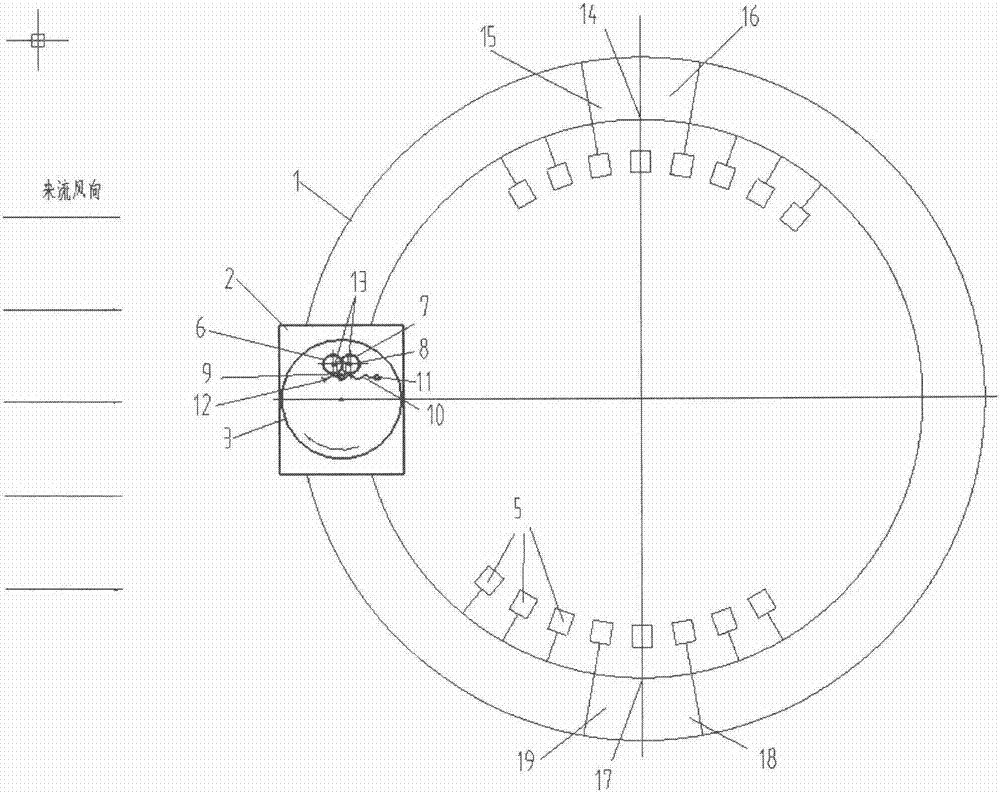

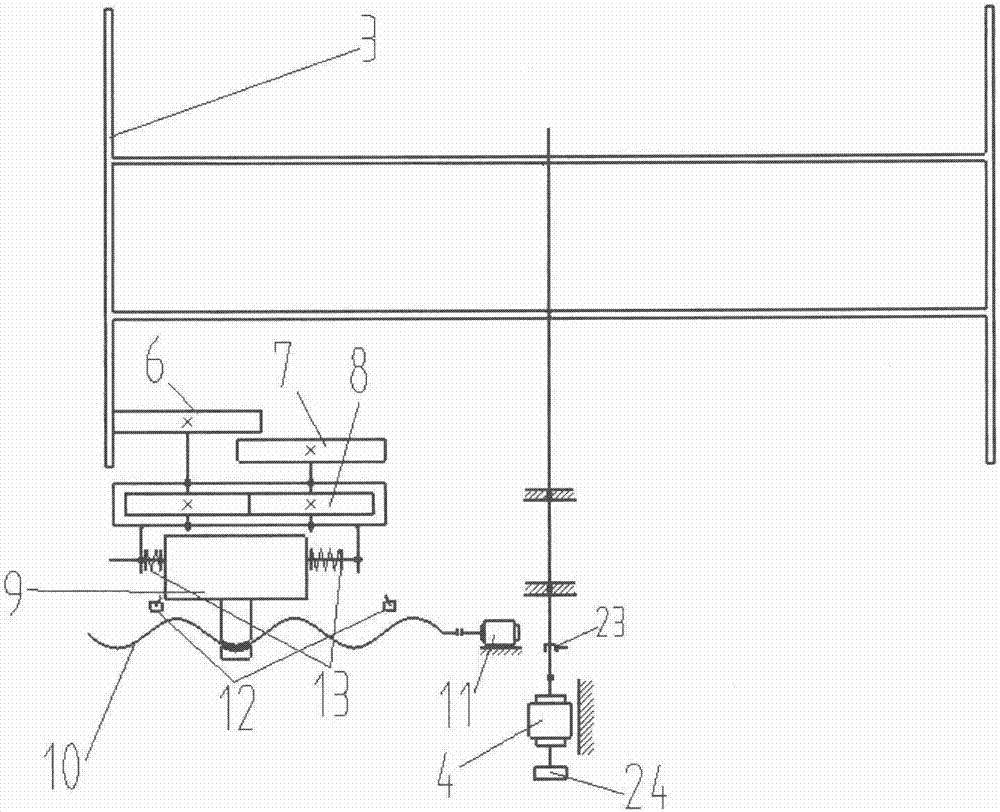

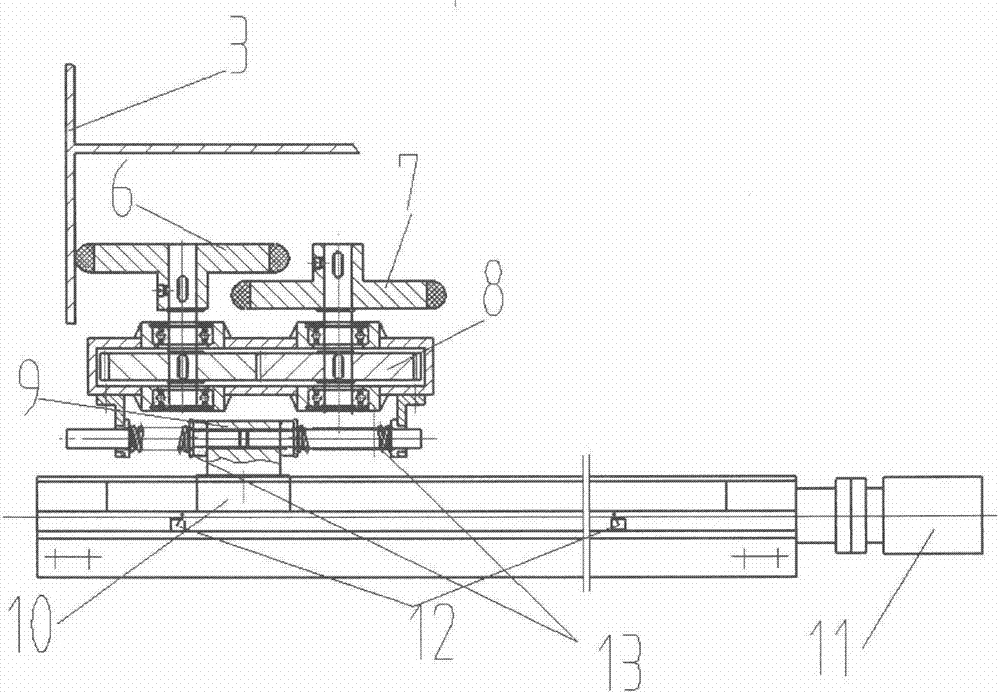

[0038] In the embodiment of the present invention, a Magnus effect vertical axis wind turbine rotor forward and reverse control and implementation method is provided. According to the on-site wind direction, the orientation of the forward and reverse conversion point of the wind turbine rotor is adjusted in real time, and at the conversion point The dynamic reversing area of the rotor is set before and after the rotor. Through the energy storage mechanism with two buffer wheels with opposite rotation directions, part of the energy of the forward rotation of the rotor can be stored and converted into the starting energy after the rotor reverses. The frequency conversion control motor is fully Using the period of time when the rotor passes through the commutation zone, gradually increase the driving frequency of the motor to a predetermined value based on the starting speed of the rotor inversion and the dynamic characteristics of the system, and reduce the energy consumption in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com