Full-automatic reinjection water (additive) system and use method thereof

A technology for re-injection of water and additives, which is applied in earth-moving drilling, machinery/engine, liquid variable-capacity machinery, etc. The effect of increasing pulverized coal carry-out rate and increasing coalbed methane production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

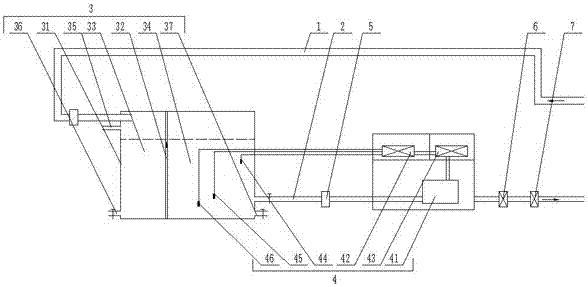

[0027] Such as figure 1 As shown, a fully automatic water injection (additive) system of the present invention includes a water return pipe 1, a water injection pipe 2, a water storage tank 3 and a control box 4. One end of the water return pipe 1 is connected to the drainage pipe of a coalbed methane well, and the other end is connected to the water storage The water inlet end of the water tank 3 is connected, one end of the water injection pipe 2 is connected with the water outlet end of the water storage tank 3, and the other end is connected to the water injection port of the coalbed methane well to inject water into the coalbed methane well. The control box 4 is arranged on the water injection pipe 2 on, used to control the entire water cycle process;

[0028] The structure of the control box 4 is: comprising a metering pump 41, a water level control module 42 and a remote control module 43, the metering pump 41 is a high pressure pump, the metering pump 41 is arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com