Cadmium-based ferromagnetic semiconductor material and preparation method thereof

A semiconductor and ferromagnetic technology, which is used in the selection of materials, the magnetic properties of inorganic materials, and the manufacture of inductors/transformers/magnets. High transition temperature and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] This embodiment provides a method for preparing a ferromagnetic semiconductor material, comprising the following steps:

[0084] 1) 3.153 grams of SrAs powder, 4.361 grams of Cd powder, 1.528 grams of As powder, 0.066 grams of Mn powder and 0.029 grams of Na 3 As powder is uniformly mixed (the atomic content ratio of Sr:Na:Cd:Mn:As is 0.97:0.03:1.94:0.06:2), and the mixture is pressed into an alumina ceramic test tube;

[0085] 2) Put the ceramic test tube with the reactant into the vacuum-sealed quartz tube;

[0086] 3) Put the quartz tube in a high-temperature furnace and sinter at a temperature of 700° C. for 30 hours.

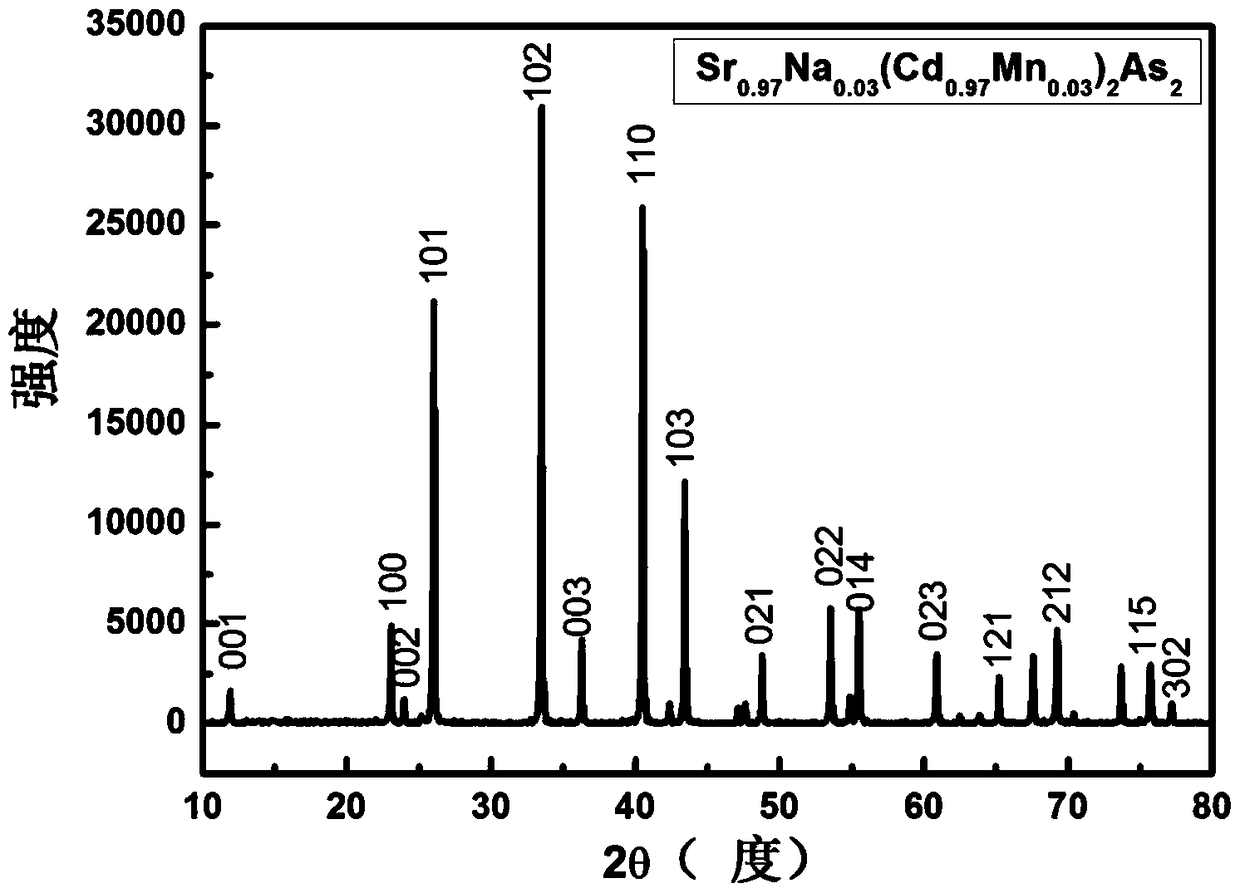

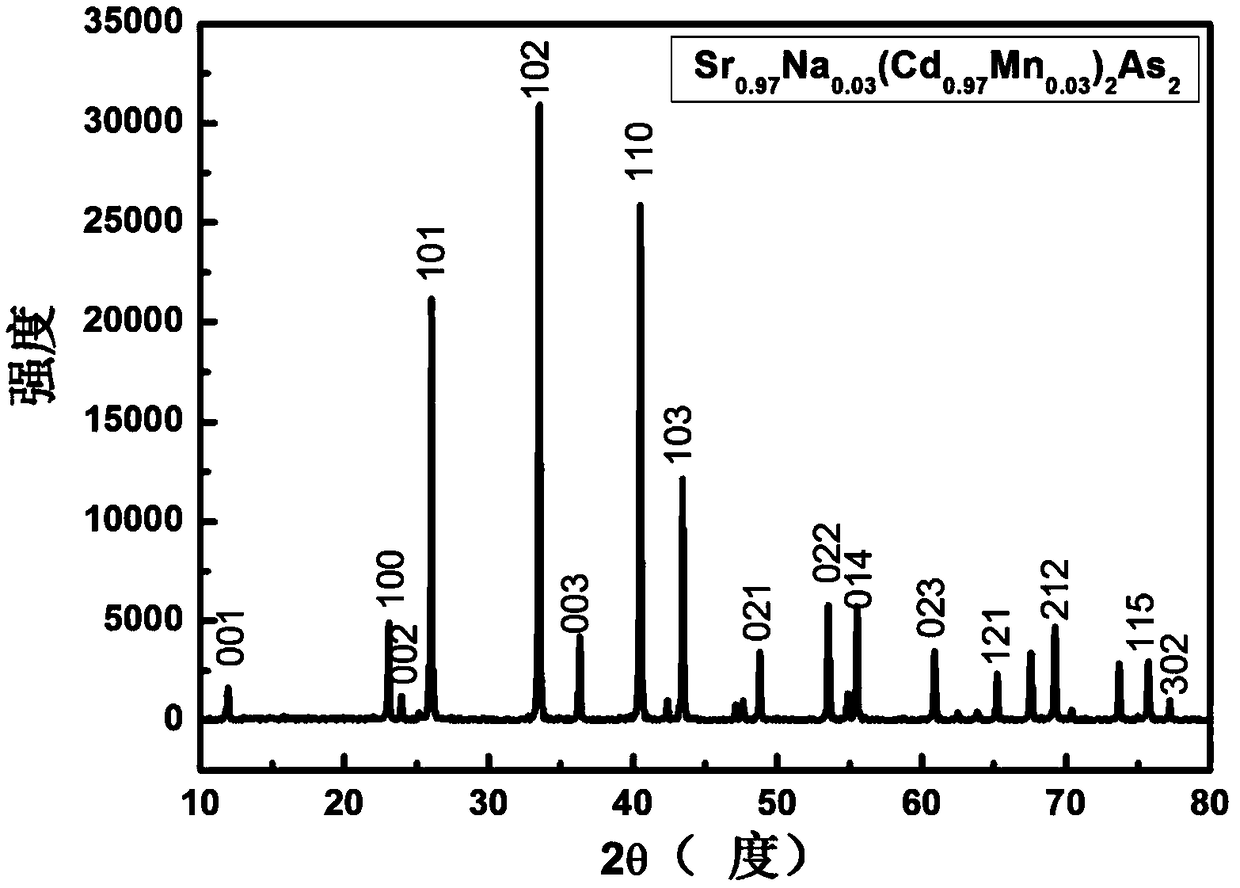

[0087] The block product obtained in step 3) was ground into powder, and subjected to X-ray diffraction analysis. figure 1 is its X-ray diffraction pattern, from figure 1 It can be concluded that the sample is a hexagonal crystal system, and all diffraction peaks have corresponding diffraction indices, and there are no miscellaneous peaks, that is...

Embodiment 2

[0094] This embodiment provides a method for preparing a ferromagnetic semiconductor material, comprising the following steps:

[0095] 1) 3.088 grams of SrAs powder, 4.272 grams of Cd powder, 1.548 grams of As powder, 0.11 grams of Mn powder and 0.048 grams of Na 3 As powder is evenly mixed (the atomic content ratio of Sr:Na:Cd:Mn:As is 0.95:0.05:1.90:0.10:2), and the mixture is put into a niobium tube under the protection of argon and sealed;

[0096] 2) Put the niobium tube containing the reactant into the quartz tube filled with argon and seal it;

[0097] 3) Put the quartz tube in a high-temperature furnace and sinter at a temperature of 750° C. for 20 hours;

[0098] 4) Grinding and mixing the sintered bulk material under the protection of argon, pressing it into tablets, putting it into a niobium tube and sealing it;

[0099] 5) Put the niobium tube into the quartz tube filled with argon and seal it;

[0100] 6) Put the quartz tube in a high-temperature furnace and s...

Embodiment 3

[0109] This embodiment provides a method for preparing a ferromagnetic semiconductor material, comprising the following steps:

[0110] 1) 3.007 grams of SrAs powder, 4.159 grams of Cd powder, 1.573 grams of As powder, 0.165 grams of Mn powder and 0.072 grams of Na 3 As powder is uniformly mixed (the atomic content ratio of Sr:Na:Cd:Mn:As is 0.925:0.075:1.85:0.15:2), and the mixture is put into a niobium tube under the protection of argon and sealed;

[0111] 2) Put the niobium tube containing the reactant into the quartz tube filled with argon and seal it;

[0112] 3) Put the quartz tube in a high-temperature furnace and sinter at a temperature of 800°C for 20 hours;

[0113] 4) Grinding and mixing the sintered bulk material under the protection of argon, pressing it into tablets, putting it into a niobium tube and sealing it;

[0114] 5) Put the niobium tube into the quartz tube filled with argon and seal it;

[0115] 6) Put the quartz tube in a high temperature furnace a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com