High-density subminiature thick-film chip resistor and manufacturing method therefor

A chip resistor and manufacturing method technology, applied in resistor manufacturing, thick film resistors, resistors and other directions, can solve the problems of low utilization rate of production materials, environmental impact of waste, low manufacturing accuracy, etc., to achieve low manufacturing costs and meet application requirements Requirement, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings.

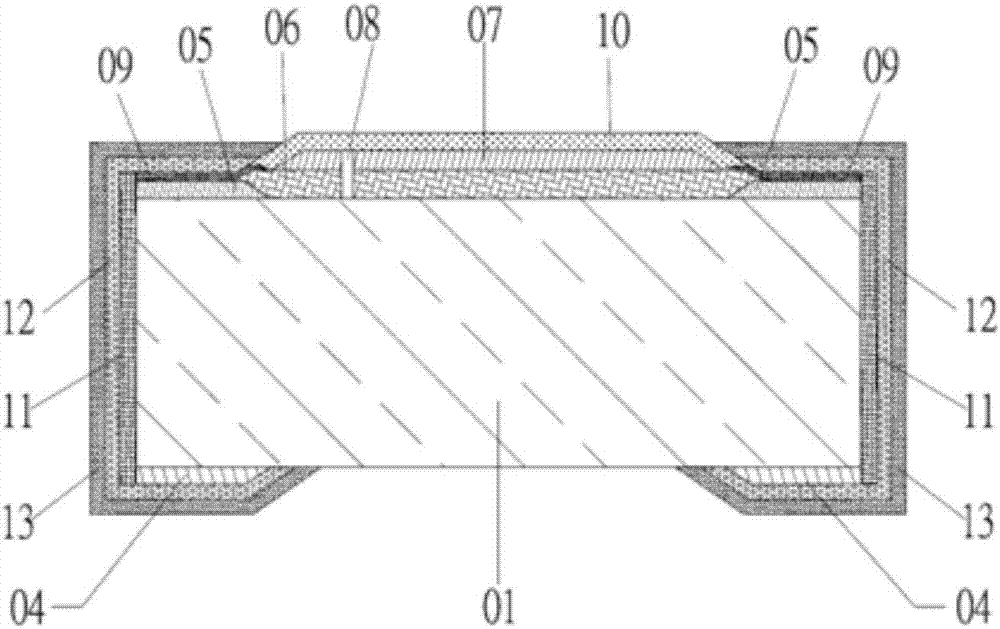

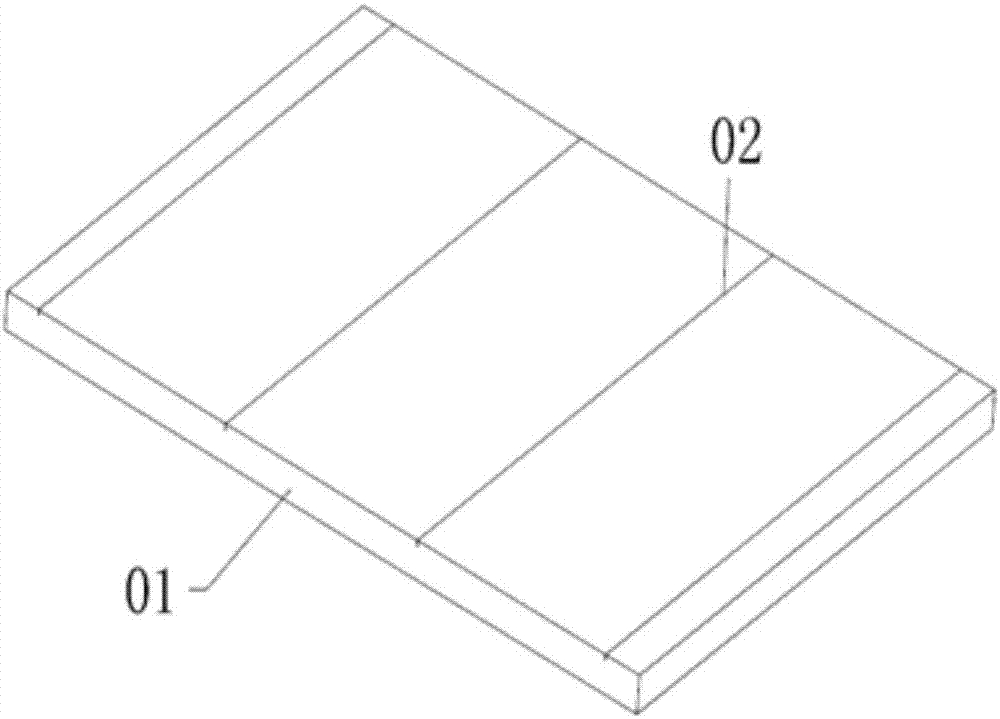

[0049] Such as figure 1 As shown, the high-density ultra-small thick film chip resistor of the present invention includes a ceramic substrate 01, the two long sides of the back of the ceramic substrate 01 are provided with folding lines 02, and the front two short sides of the ceramic substrate 01 are provided with There are folded grain lines 03, the folded grain lines 02 and the folded grain lines 03 are vertically arranged in the space, the back electrode 04 is printed on the back of the ceramic substrate 01, and the folded grain lines 03 are printed on the front of the ceramic substrate 01. The inner side is symmetrically printed with a first front electrode 05, and a resistance body 06 is printed between the two first front electrodes 05. The upper surface of the resistance body 06 is provided with a first protective layer 07, and the resistance body 06 and A rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com